Production and producing device for aspherical moulded glass

A manufacturing method and aspheric technology, which are applied in glass manufacturing equipment, glass pressing, manufacturing tools, etc., can solve the problems affecting the accuracy of aspheric surfaces, uneven surfaces of aspheric glass, and difficult polishing, and reduce thermal expansion. , Improve the Ra value, the effect of good shape accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is a method for manufacturing an aspheric molded glass with a nanoscale surface. The manufacturing method will be described below in conjunction with specific diagrams.

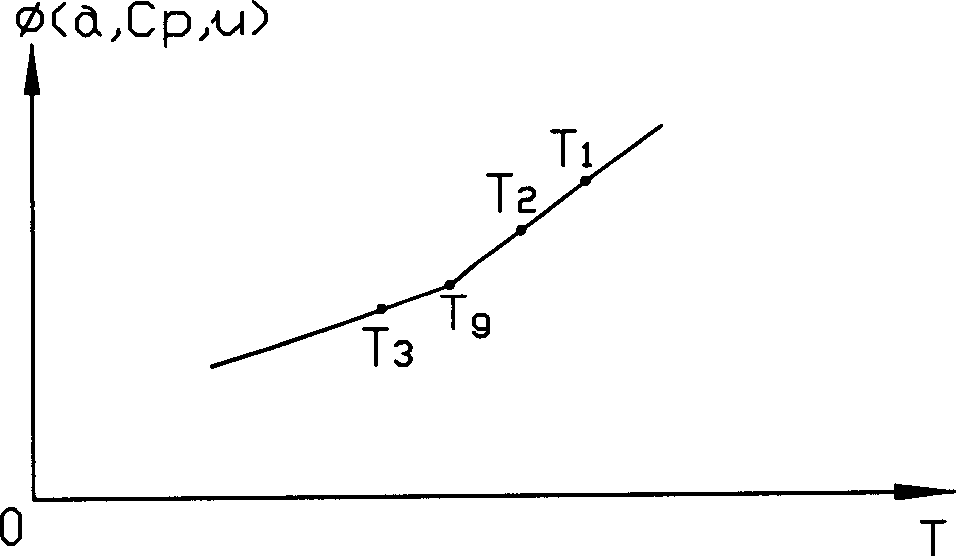

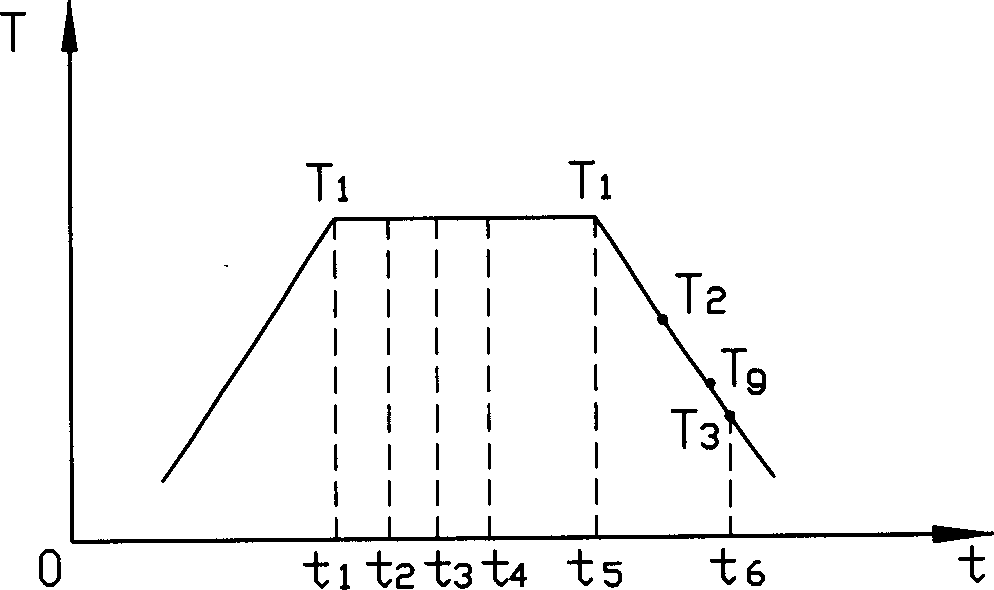

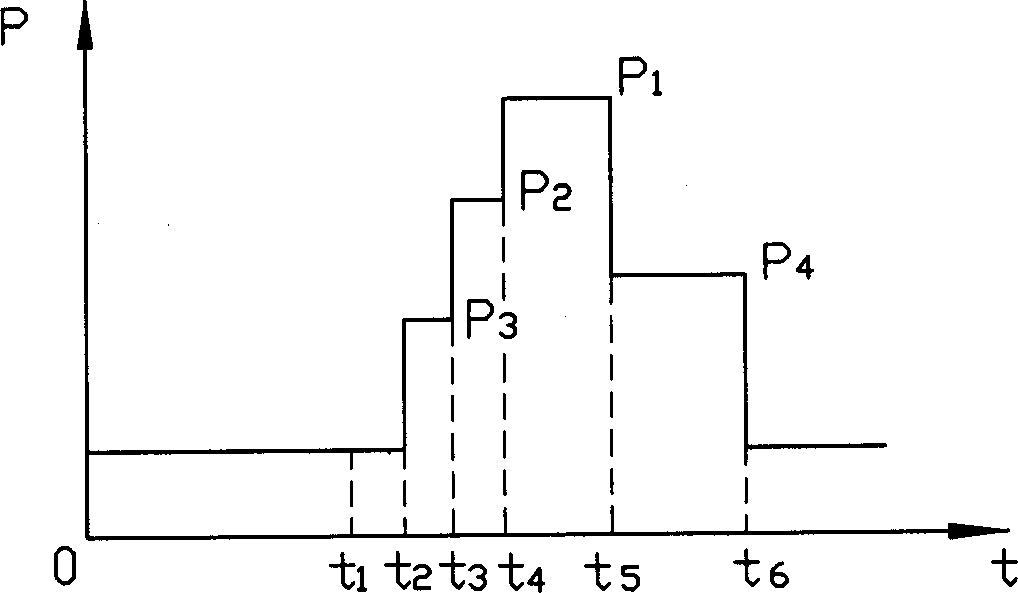

[0026] See figure 1 , the ordinate Φ(α, Cp, u) function represents the physical and mechanical properties of the aspheric molded glass, where the physical parameters: α represents the thermal expansion coefficient, Cp represents the heat capacity, u represents the viscosity of the glass; the abscissa represents the temperature, the curve in this figure Middle T 1 Indicates the forming temperature, T 2 Represents transition temperature, Tg represents glass transition temperature, T 3 Indicates the cooling temperature. In the glass molding process, the Tg point temperature is more important in molded glass. The material of molded glass is different, and its glass transition temperature Tg is correspondingly different. Usually after determining the Tg temperature, the forming tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com