Light-conducting board and backlight mould set

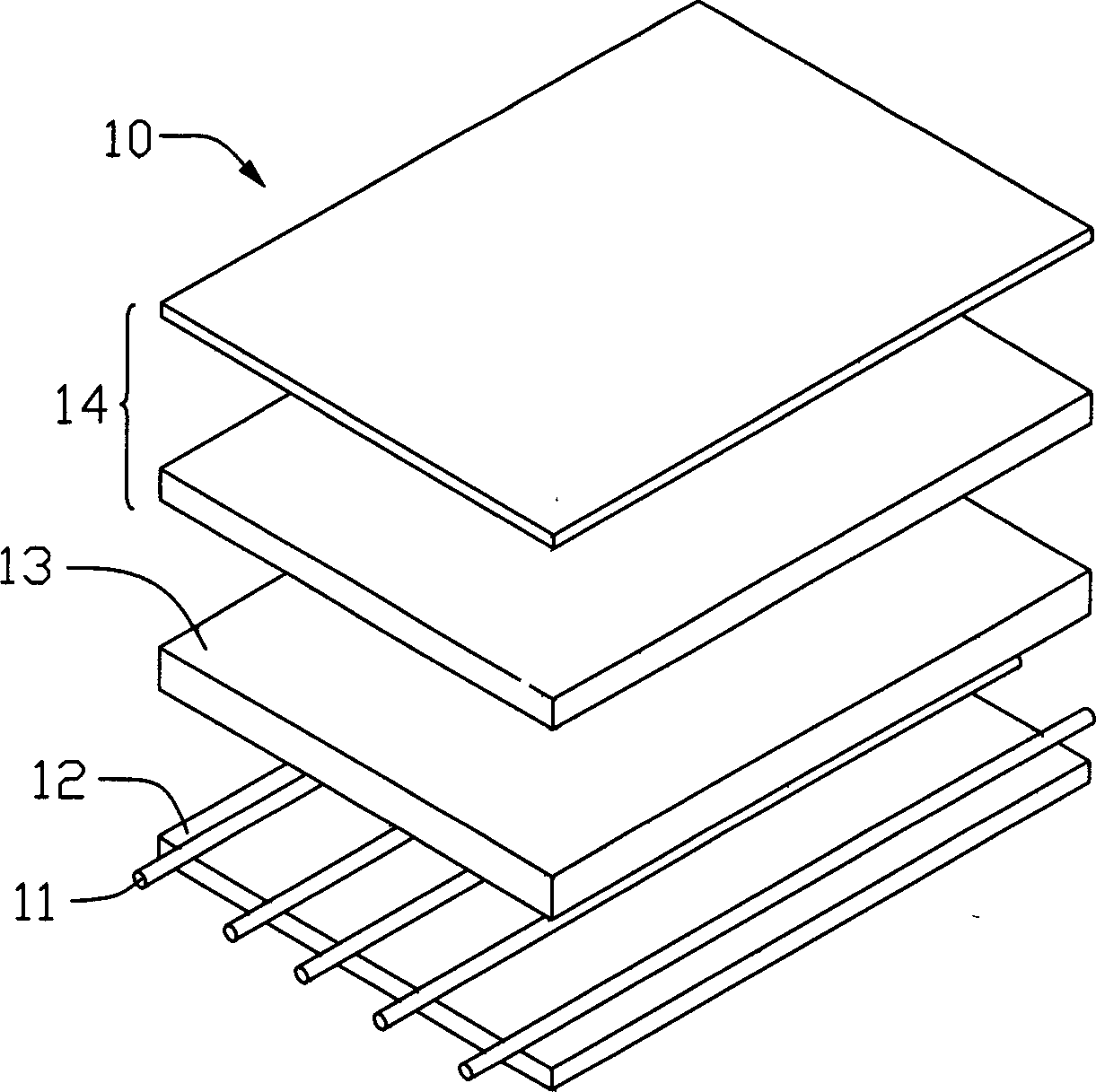

A technology of backlight module and light guide plate, which is applied in the direction of light guide, optics, optical components, etc., can solve the problems of difficult liquid crystal display, high cost, and difficult processing of light guide plate, and achieve the effect of simplifying the system and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

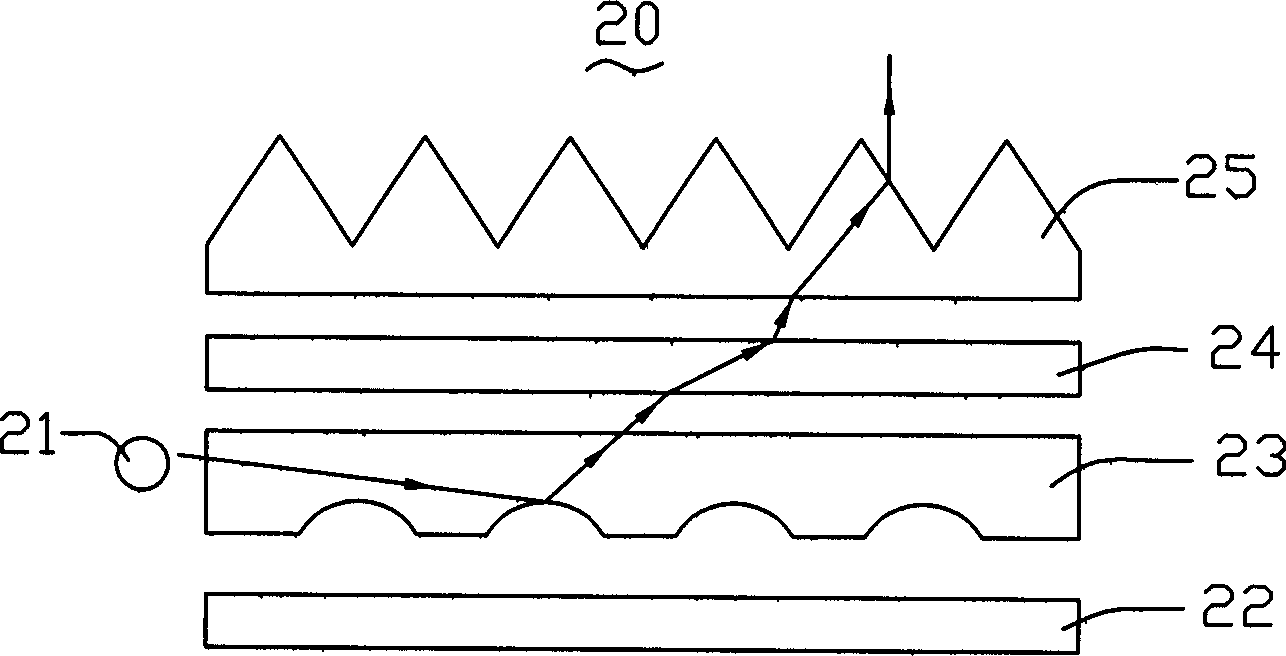

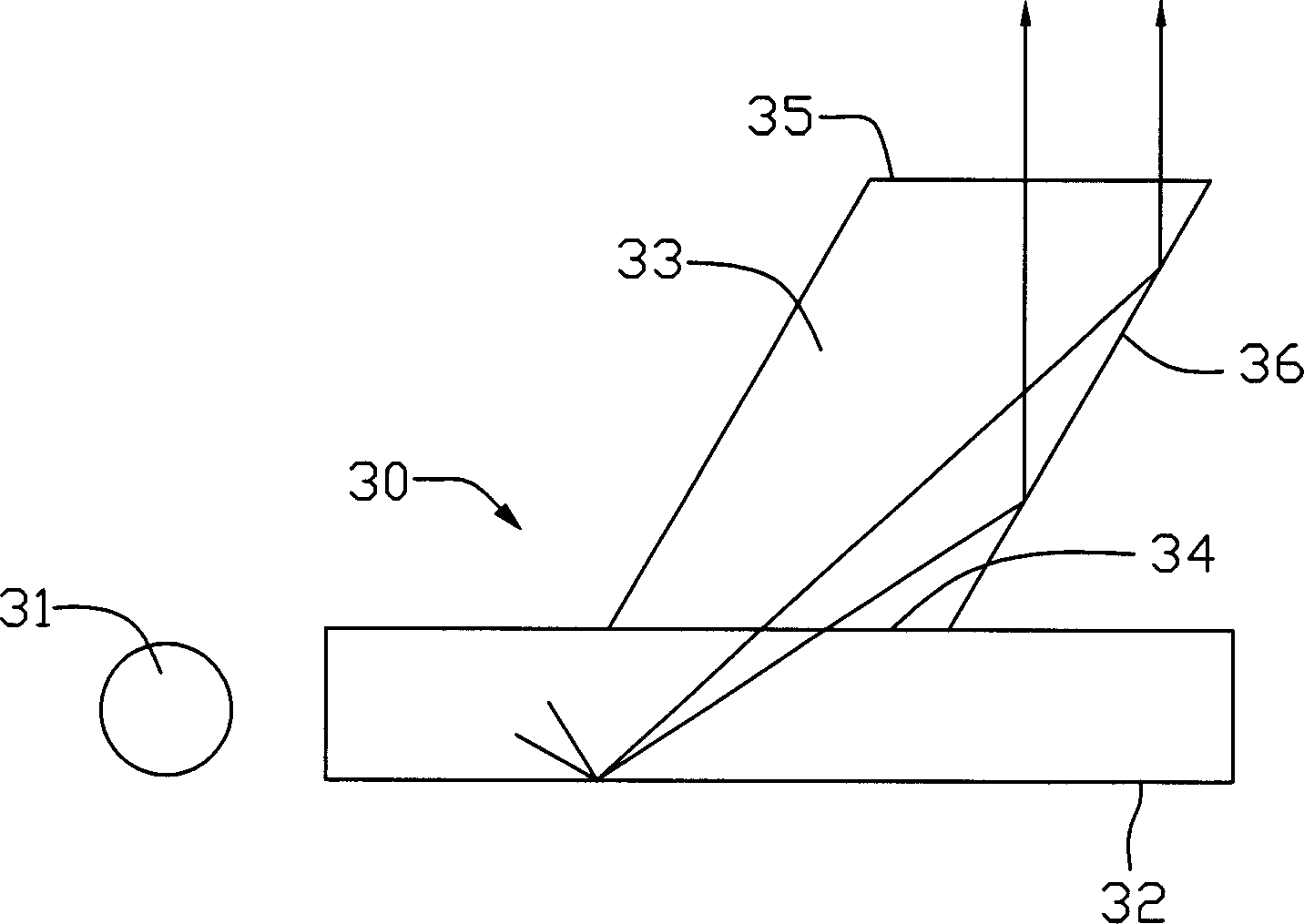

[0036]The light guide plate and the backlight module of the present invention will be further described in detail with reference to the accompanying drawings and multiple embodiments.

[0037] Please also refer to Figure 6 and Figure 7 The first embodiment of the present invention provides a 14.1-inch flat light guide plate 60, including two incident surfaces 62, 62', an outgoing surface 63, a reflective surface 64 opposite to the outgoing surface 63, and other two sides (not shown). marked). Wherein, the two incident surfaces 62, 62' are formed on the sides of the light guide plate 60 adjacent to the two cold cathode tubes 61, 61'. The emitting surface 63 is formed on the top surface of the light guide plate 60 . The reflective surface 64 is formed on the bottom surface of the light guide plate 60 . The reflective surface 64 is also formed with several V-shaped microstructures 640 protruding from the light guide plate 60 along the direction away from the outgoing surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com