Low noise reactor and its prodacing method

A manufacturing method and reactor technology, which are used in the manufacture of inductors/transformers/magnets, transformers/inductor cores, and circuits, etc. problems, to achieve the effect of preventing vibration or collision, preventing degradation, and improving fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

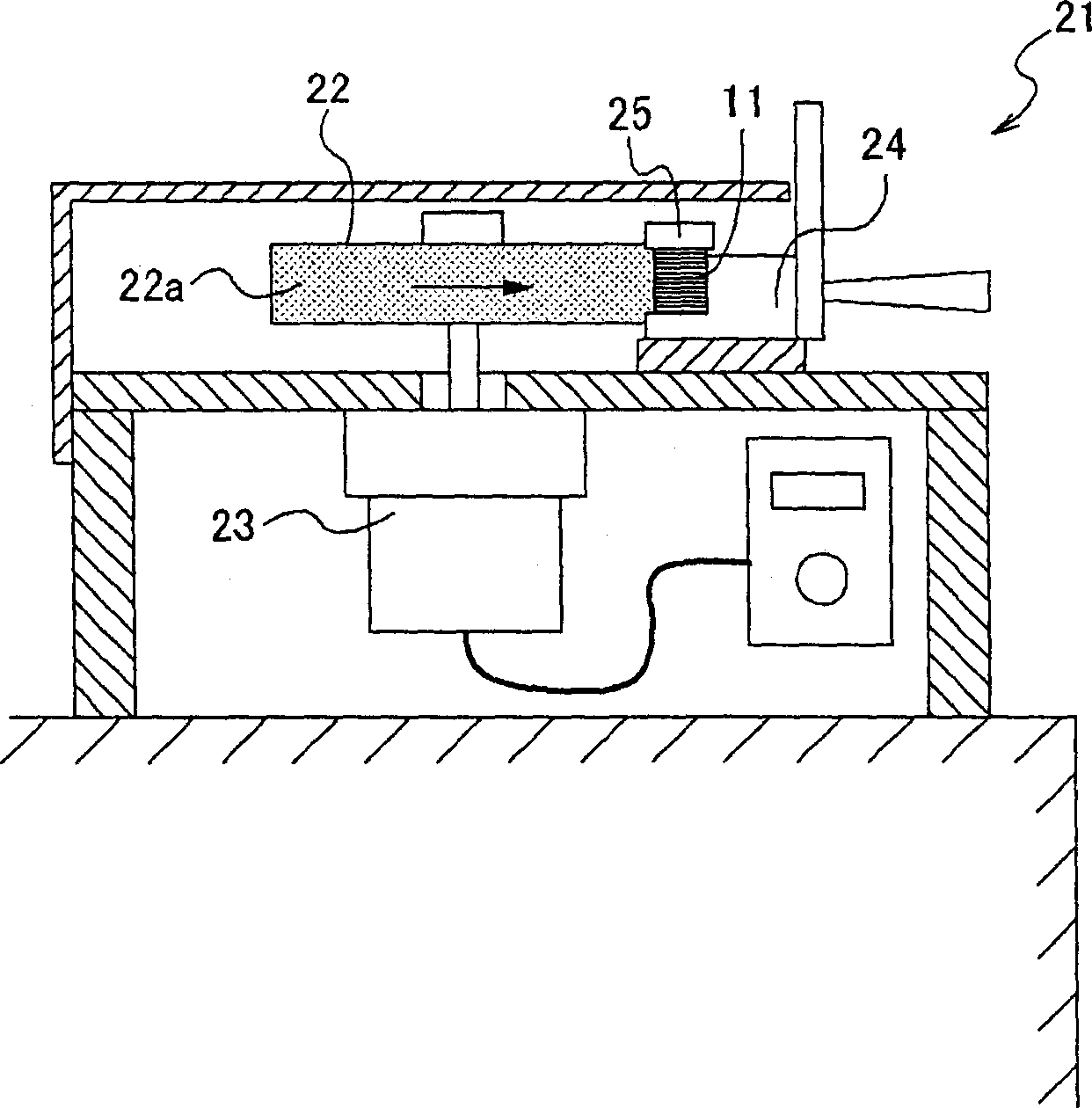

[0035] An embodiment of the present invention will be described below with reference to the accompanying drawings.

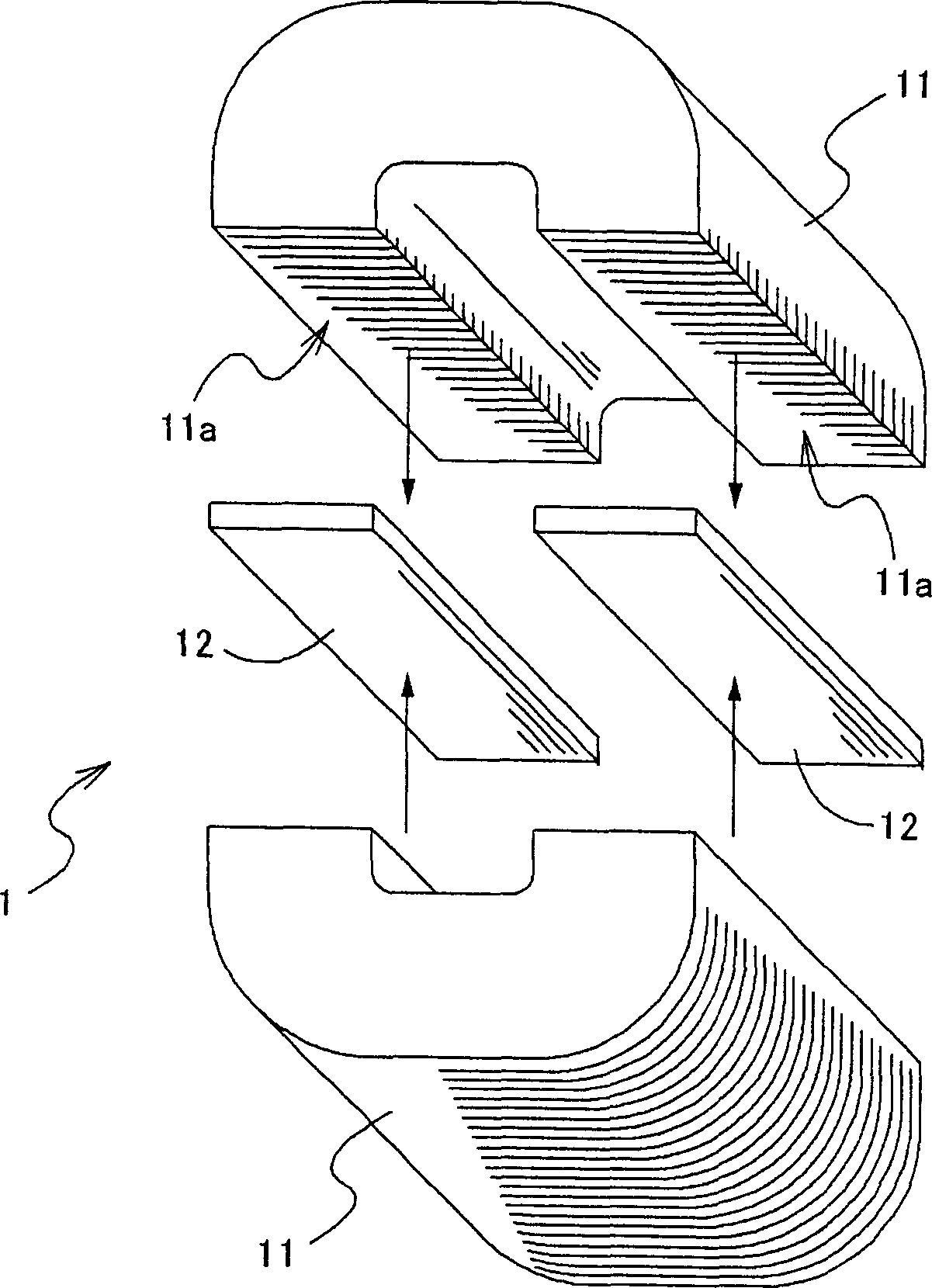

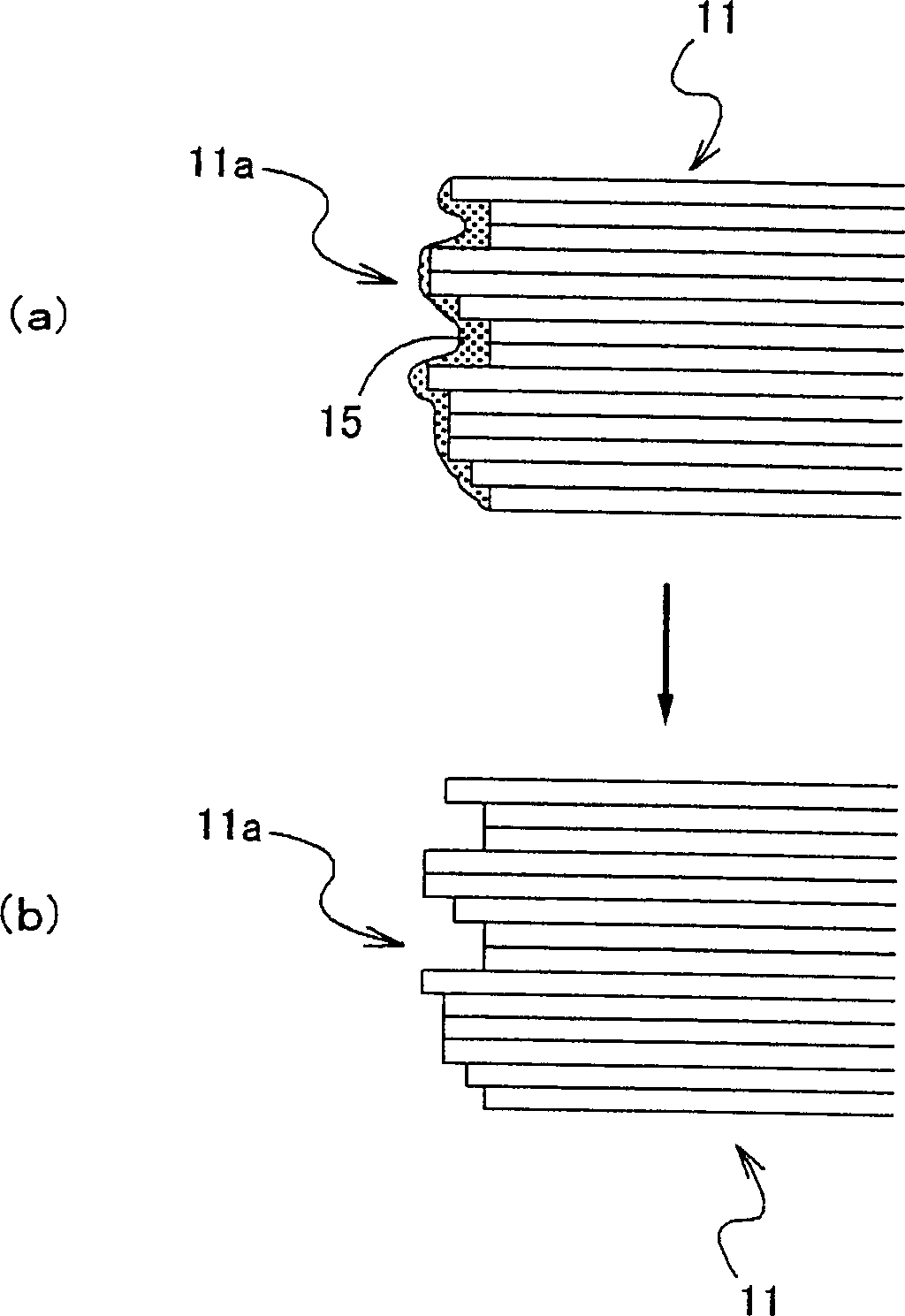

[0036] figure 1 A core body 1 of a low noise reactor of the present invention is shown. The core 1 comprises a plurality of laminated steel plates 11 having surfaces 11 a abutting against each other via spacers 12 .

[0037] Each laminated steel plate 11 is formed by laminating a plurality of substantially U-shaped steel plate layers. Laminated steel sheets 11 are impregnated with varnish, so that the steel sheet layers are bonded to each other by the impregnated varnish.

[0038] Instead of the impregnating varnish, epoxy or acrylic impregnating adhesives can also be used to bond the steel sheet layers to each other.

[0039] Each gap spacer 12 interposed between the abutting surfaces 11a of the laminated steel plates 11 may be made of a non-magnetic insulating member such as ceramics, glass, glass epoxy matrix, or the like.

[0040] The abutting surface 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com