Solid-state laser generator

一种激光发生器、固态的技术,应用在激光器、声子激发器、激光器零部件等方向,能够解决不能容易增加固态激光介质数量等问题,达到高输出的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

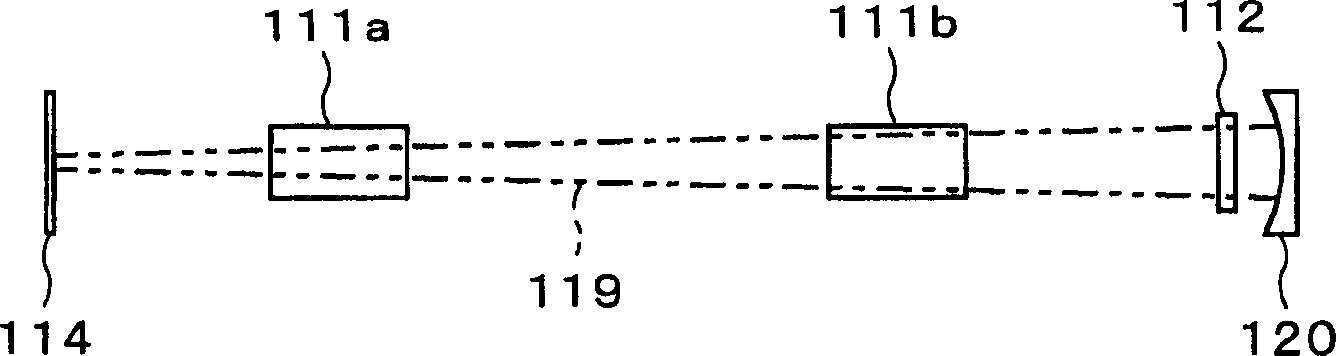

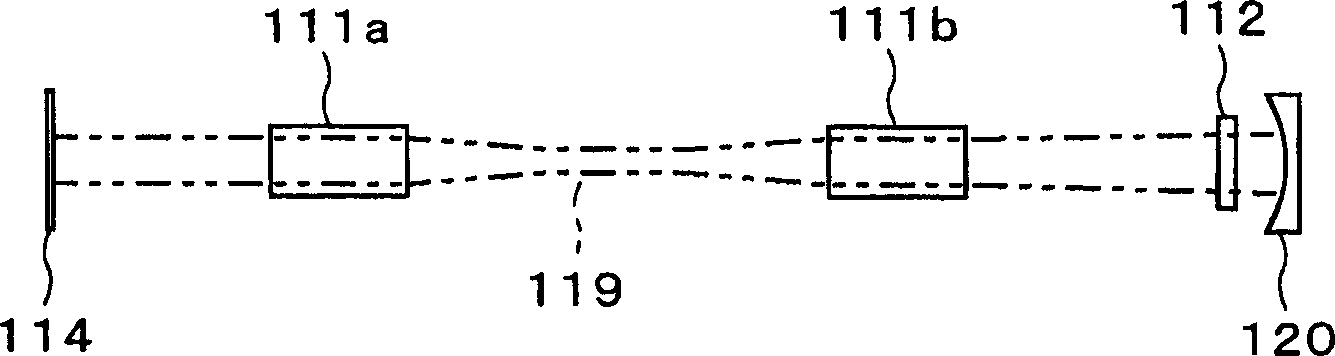

[0030] A solid-state laser generator according to an embodiment of the present invention will be described in detail below with reference to the accompanying drawings. First, a solid-state laser generator according to a first embodiment of the present invention will be described. image 3 is a diagram showing the configuration of a resonator in the solid-state laser generator of this embodiment. The solid-state laser generator of the present embodiment is a solid-state laser generator employing intracavity frequency conversion having a resonator for performing second harmonic conversion.

[0031] The resonator 10 in the solid-state laser generator of the present embodiment has: a Q switch 3a; a solid-state laser medium 1a, which is used to amplify the fundamental frequency laser 9; a Q switch 3b; a Q switch 3c; a solid-state laser medium 1b, which is used to amplify the fundamental frequency laser 9; Fundamental frequency laser 9 amplification; And Q switch 3d, they are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com