Six point positioning base line transfer method for refine casting blade

A six-point positioning and blade technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve problems affecting blade quality, blade surface indentation, heavy weight, etc., to reduce labor intensity, accurate processing standards, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

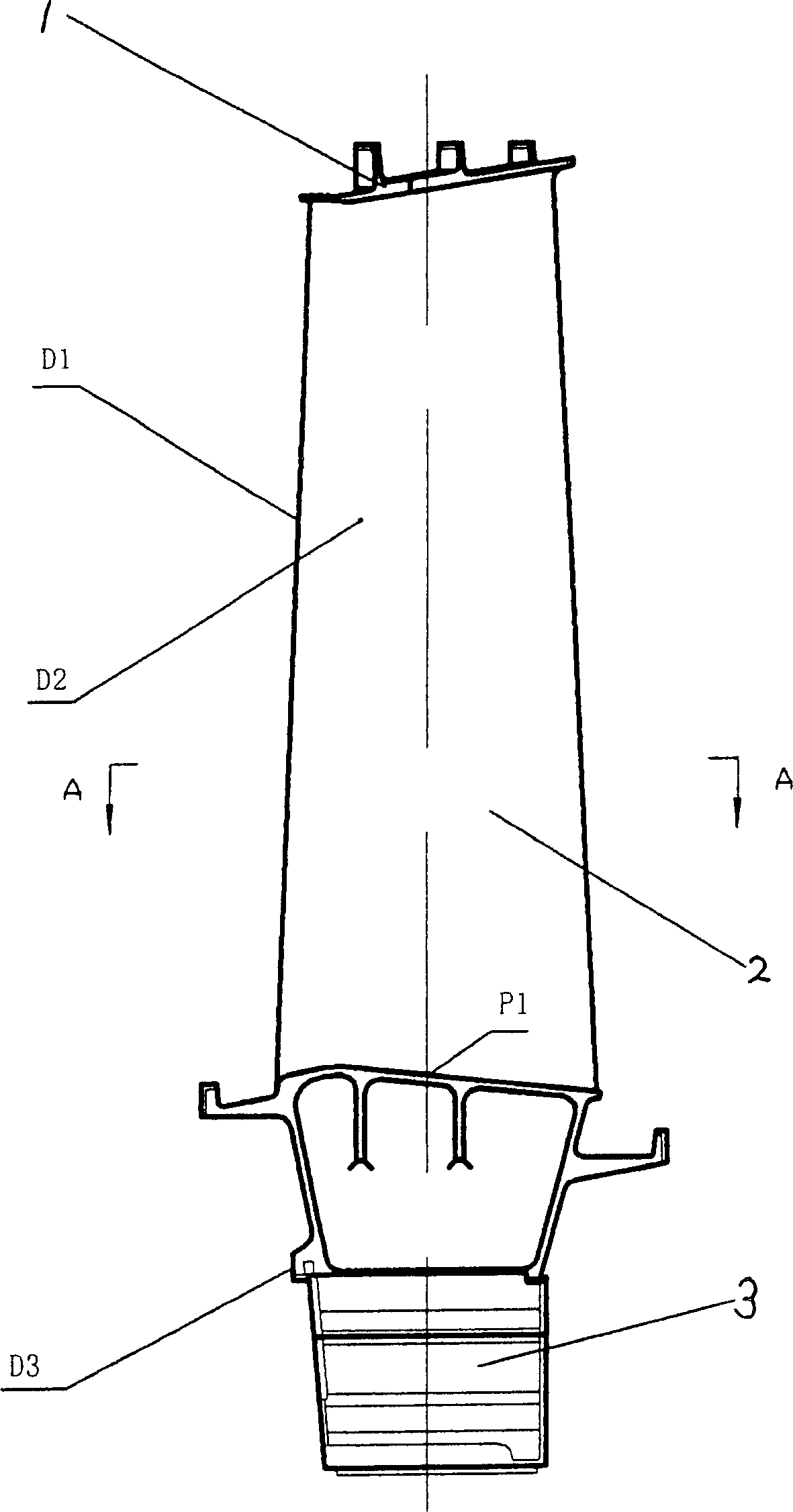

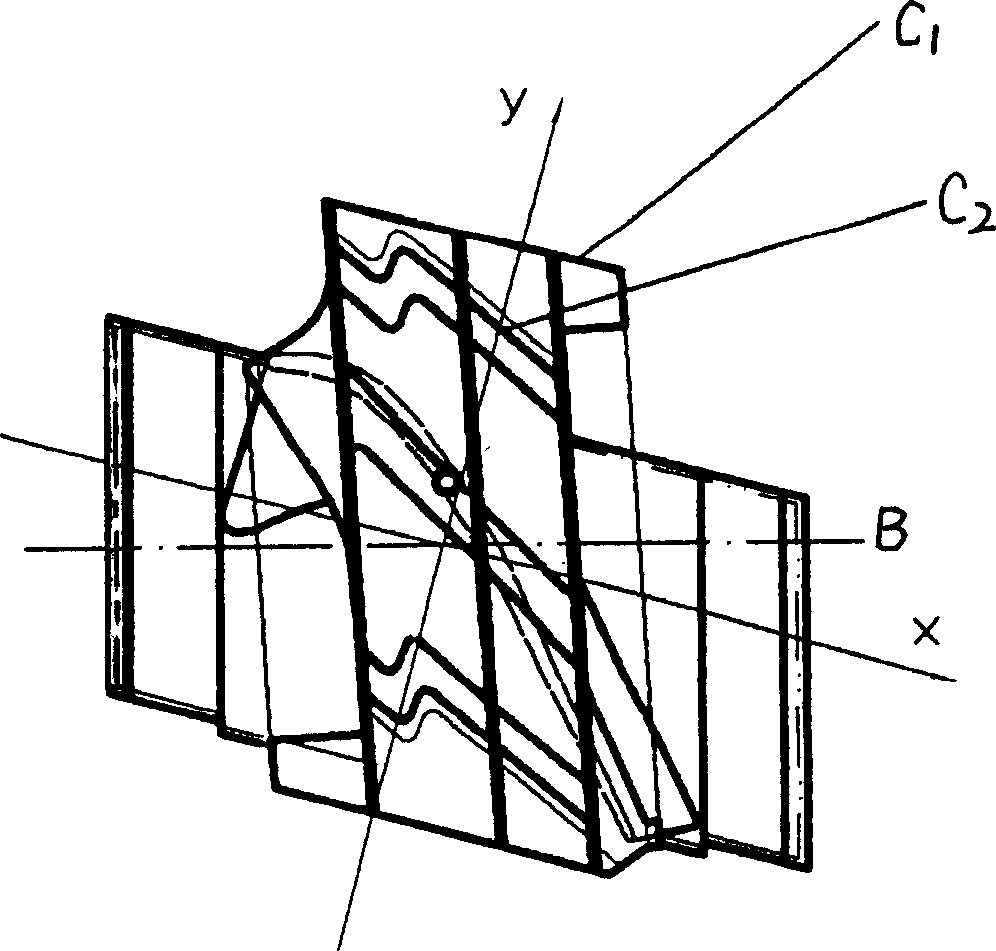

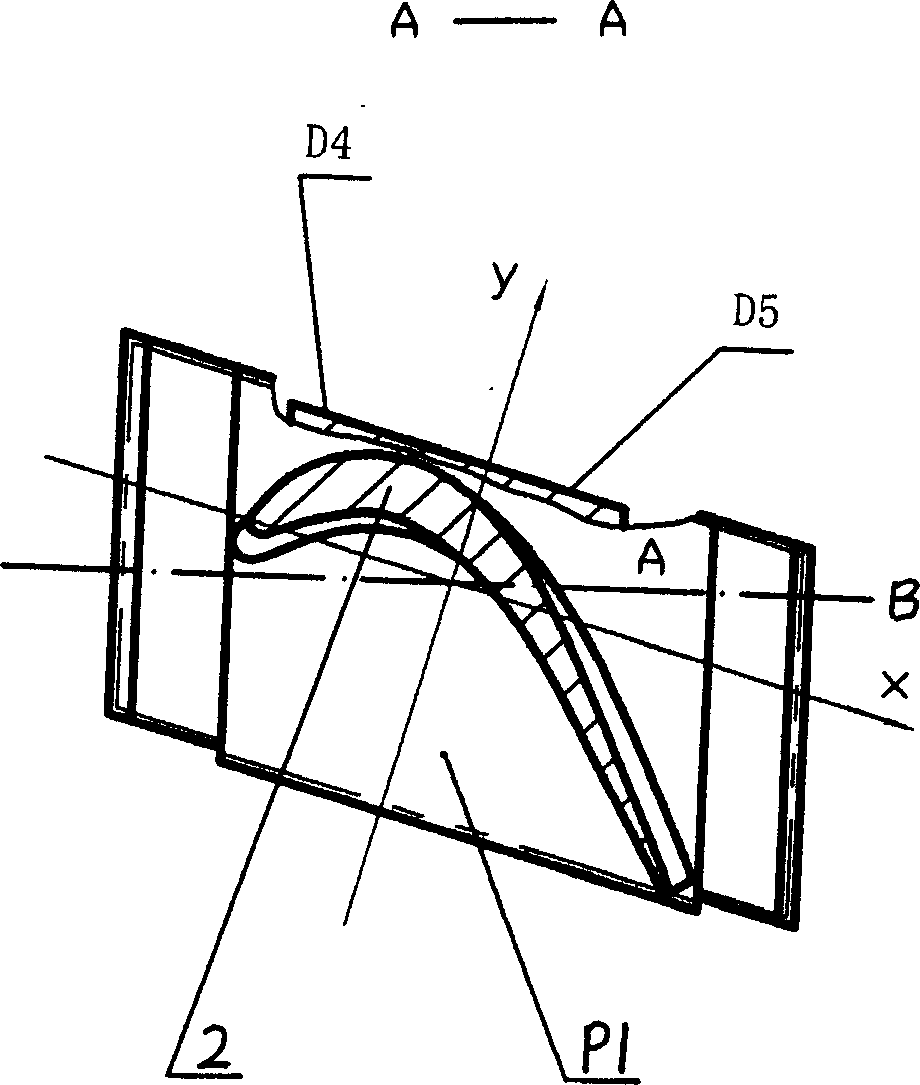

[0020] Embodiment 1: with heavy-duty gas turbine blade (such as figure 1 , figure 2 , image 3 Shown) as an example, the method for its six-point positioning reference transfer includes the following steps:

[0021] 1. Adjust the six-point positioning fixture: the six-point positioning fixture is a fixture for clamping the workpiece on the machine tool. The six-point positioning fixture is determined according to the six positioning points D1, D2, D3, D4, D5, and P1 on the precision casting blade body The position and orientation of the hold-down mechanism;

[0022] 2. Casting blade wool: Compared with the size of the outer contour C2 of the finished precision casting blade, there is a straight surface on the blade edge C2 on the side of the wool crown 1, and the distance between the remaining straight surface and the edge C2 of the finished blade is the smallest The range is 2mm ~ 4mm, for subsequent wire cutting processing applications;

[0023] 3. Install the six-point...

Embodiment 2

[0026] Embodiment 2: with certain type submarine turbine blade (as Figure 4 , Figure 5 , Image 6 , Figure 7 Shown) as an example, the method for its six-point positioning reference transfer includes the following steps:

[0027] 1. Adjust the six-point positioning fixture: the six-point positioning fixture is a fixture for clamping the workpiece on the machine tool. The six-point positioning fixture is determined according to the six positioning points S1, S2, S3, S4, S5, and S6 on the precision casting blade body The position and orientation of the hold-down mechanism;

[0028] 2. Casting blade wool: Compared with the size of the outer profile C4 of the finished precision casting blade, there is a straight surface on the edge C4 of the blade crown 1 side of the wool material, and the distance between the remaining straight surface and the edge C4 of the finished blade is the smallest The range is 2mm ~ 4mm, for subsequent wire cutting processing applications;

[0029...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com