Anaerobic ammonia oxidation reactor

An anaerobic ammonium oxidation and reactor technology, applied in the field of anaerobic ammonium oxidation reactors, can solve the problems of being unfavorable for the separation of granular sludge and muddy water, destroying the structure of activated sludge, and high nitrogen content in effluent, so as to achieve the separation of muddy water. Good effect, high reaction potential, high influent ammonia concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

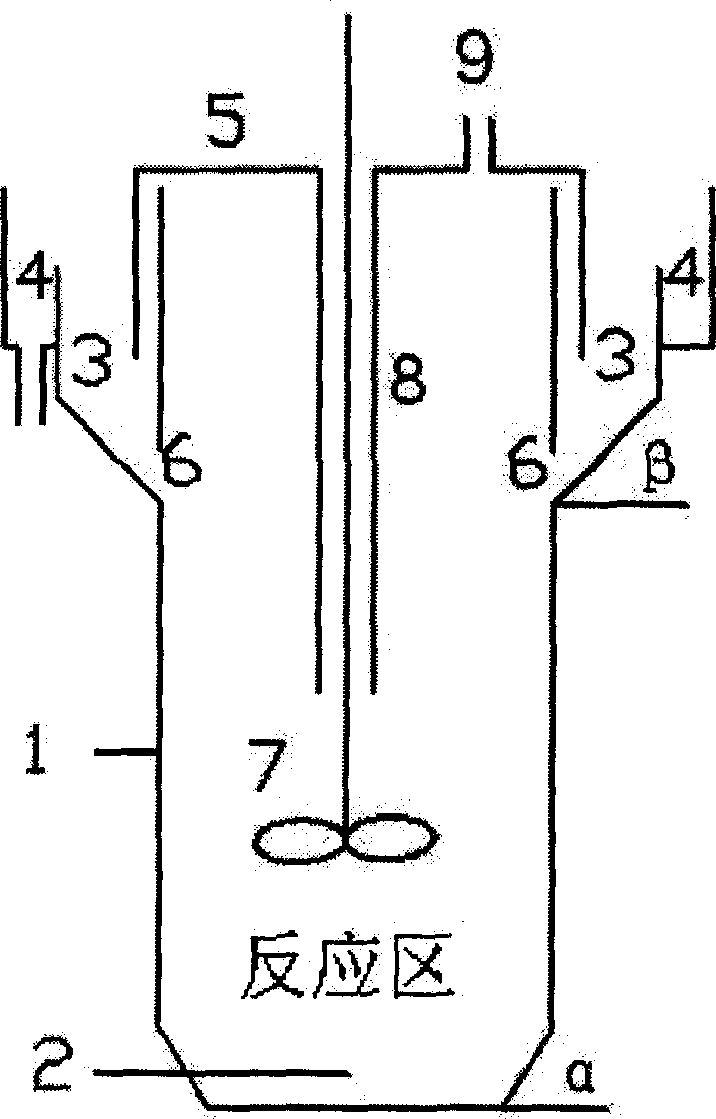

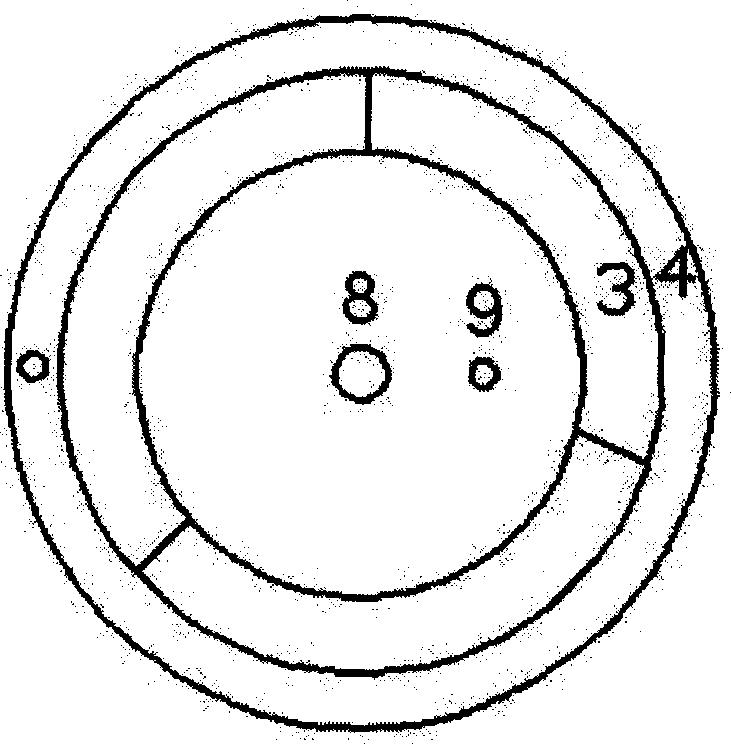

[0011] As shown in the figure, the anammox reactor has a cylindrical reactor body 1, a water inlet pipe 2 is provided at the lower end of the reactor body, and a sludge sedimentation area 3, an overflow weir 4, and a sealing cover 5 are arranged at the upper end of the reactor body , a sludge reflow joint 6 is provided at the lower end of the sludge sedimentation area, an agitator 7 is provided inside the reactor, a stirring shaft sleeve 8 and an air outlet 9 are provided on the sealing cover, and the anammox bacteria in the reactor take the form of particles The form of sludge exists.

[0012] The height-to-diameter ratio H / D of the cylindrical reactor body 1 is 1.5-2.5, and the horizontal inclination angle α of the lower slope is 50°-55°. The height of the sludge settling area 3 accounts for 1 / 5-1 / 6 of the height of the reactor body, and the volume of the sludge settling area accounts for 1 / 6-1 / 7 of the total volume. The angle β between them is 50°~55°. The water inlet pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com