Integrated baffle-type autotrophic biological denitrification reactor

A technology of biological denitrification and reactor, which is applied in chemical instruments and methods, biological water/sewage treatment, anaerobic digestion treatment, etc. Rich group structure and improved impact load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

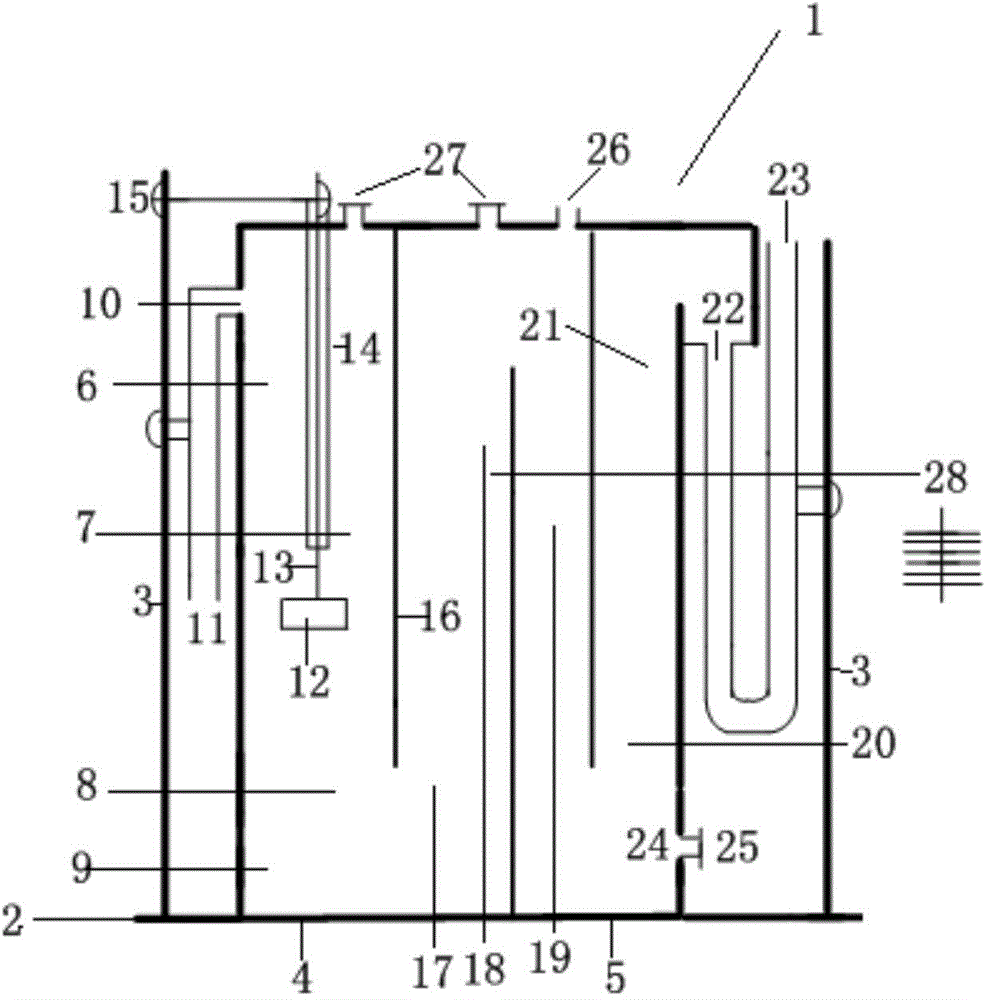

[0022] refer to figure 1 , an integrated baffled autotrophic biological denitrification reactor, comprising a reactor body 1, a base 2 and a support 3, the reactor body 1 and the support 3 are fixed on the base 2, The reactor body 1 is provided with a first baffle 16, and the first baffle 16 divides the reactor body 1 into a short-path nitrification unit 4 and an anammox unit 5, and the The upper end of the first baffle plate 16 is connected with the top of the reactor body 1, and a gap is left between the lower end and the bottom of the reactor body 1;

[0023] The short-range nitrification unit 4 is divided into a water inlet area 6, a reaction area 7, a first water outlet area 8 and a first sedimentation area 9 from top to bottom, and a water inlet pipe 11 is provided above the water inlet area 6. Water inlet 10; the bottom end of the reaction zone 7 is provided with an aeration head 12, and the aeration head 12 is connected with the aeration pipe 13 passing through the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com