Novel anammox biomembrane reactor and biological denitrifying method thereof

A technology of biofilm reactor and anaerobic ammonium oxidation, which is applied in chemical instruments and methods, anaerobic digestion treatment, biological water/sewage treatment, etc., can solve the problems of sludge loss, prevent sludge loss and improve detoxification Nitrogen efficiency, effect of improving interception performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

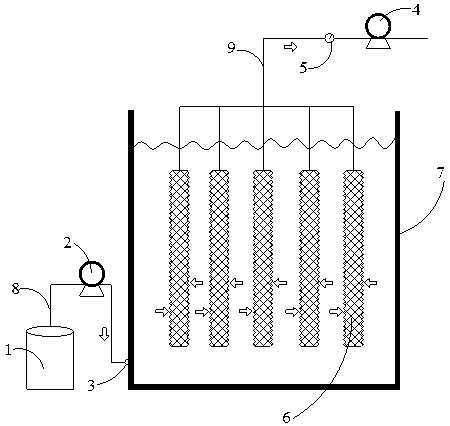

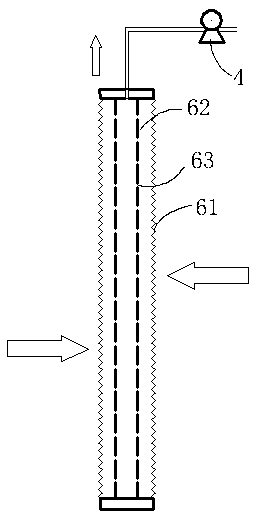

[0033] Such as figure 1 Shown is a schematic structural diagram of the anammox biofilm reactor of the present invention, including a reaction tank 7 and an inlet tank 1 . The lower part of the reaction pool 7 is provided with a water inlet. The water inlet tank 1 is connected to the water inlet of the reaction tank 7 through a water inlet pipe 8, and the water inlet pipe 8 is provided with a water inlet pump 2 and a water inlet valve 3. The water inlet valve 3 is preferably arranged at the position where the water inlet pipe 8 is connected to the water inlet. Five filter assemblies 6 are arranged in the reaction tank, and the filter assemblies include a support structure with a cavity and permeable water and non-woven fabrics covering the outer surface of the support structure. The top of each filter assembly 6 is connected to the water outlet pump 4 through an outlet pipe 9 , The outlet pipe 9 is provided with a vacuum pressure gauge 5. The outlet pipe 9 communicates with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com