Wheel type explosion-proof hydraulic brake

A technology of hydraulic brakes and wheel brakes, which is applied in the direction of drum brakes, brake types, brake actuators, etc., and can solve the problems of complex hydraulic systems, inapplicability, and high requirements for electronic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

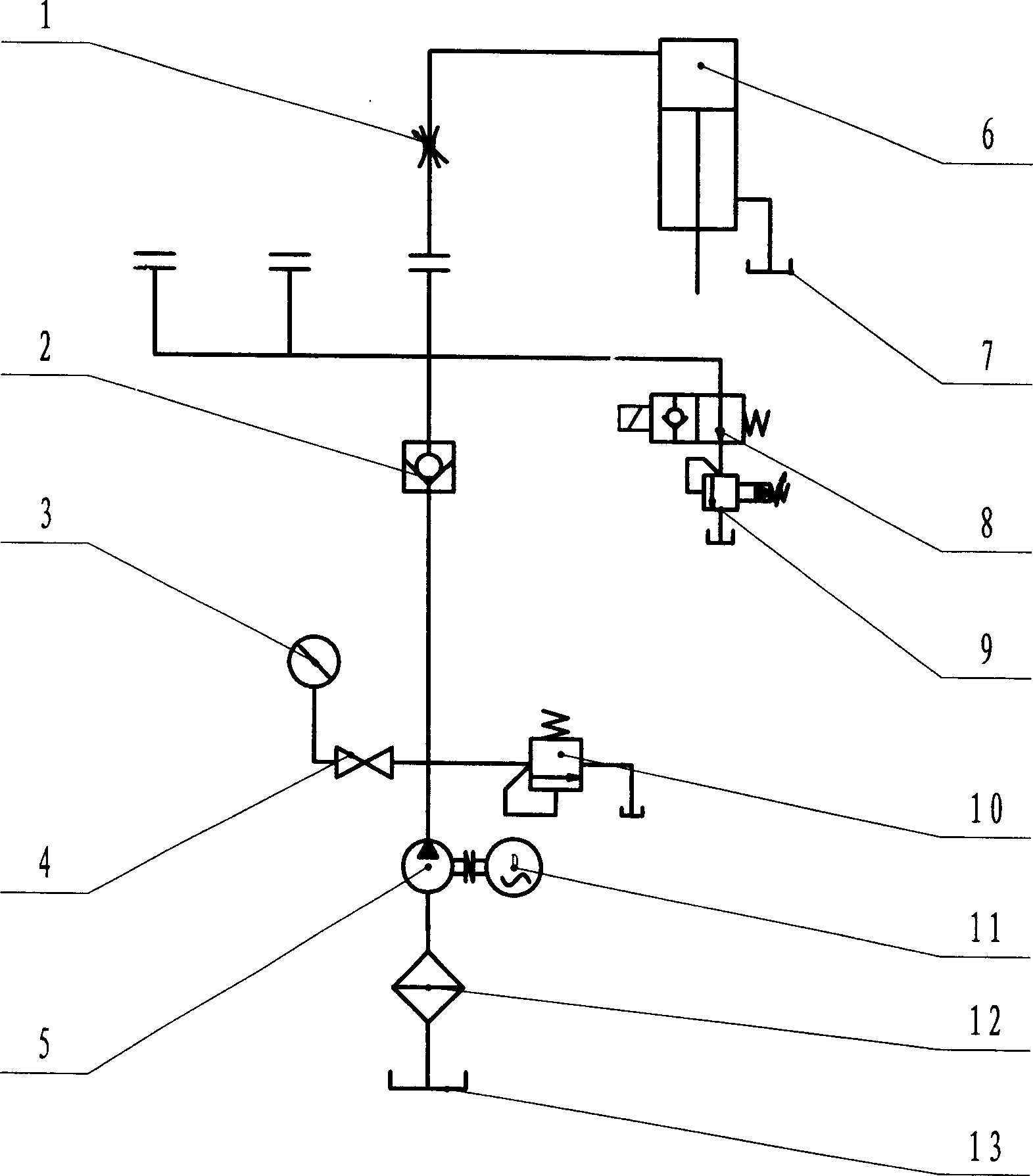

Method used

Image

Examples

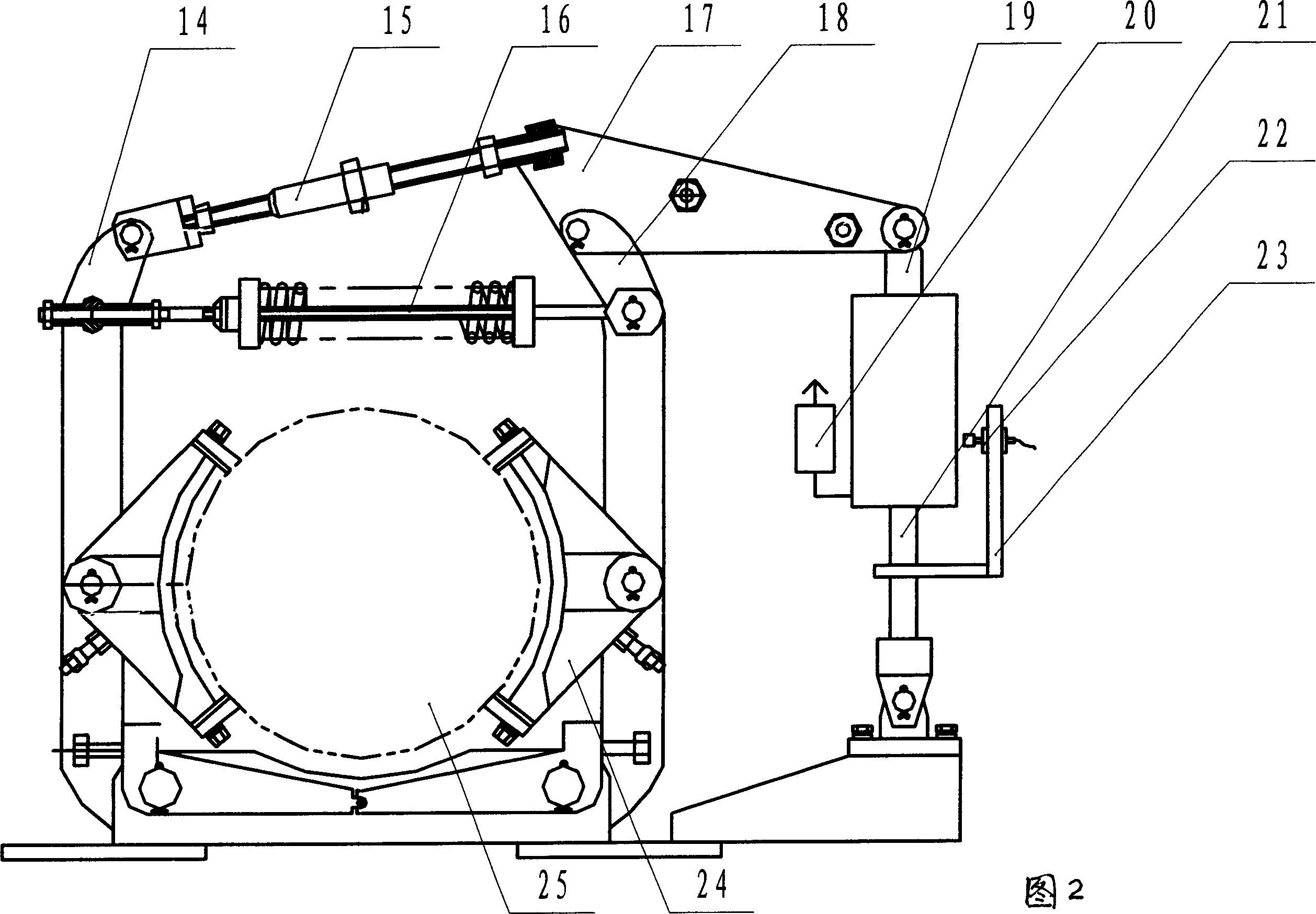

Embodiment Construction

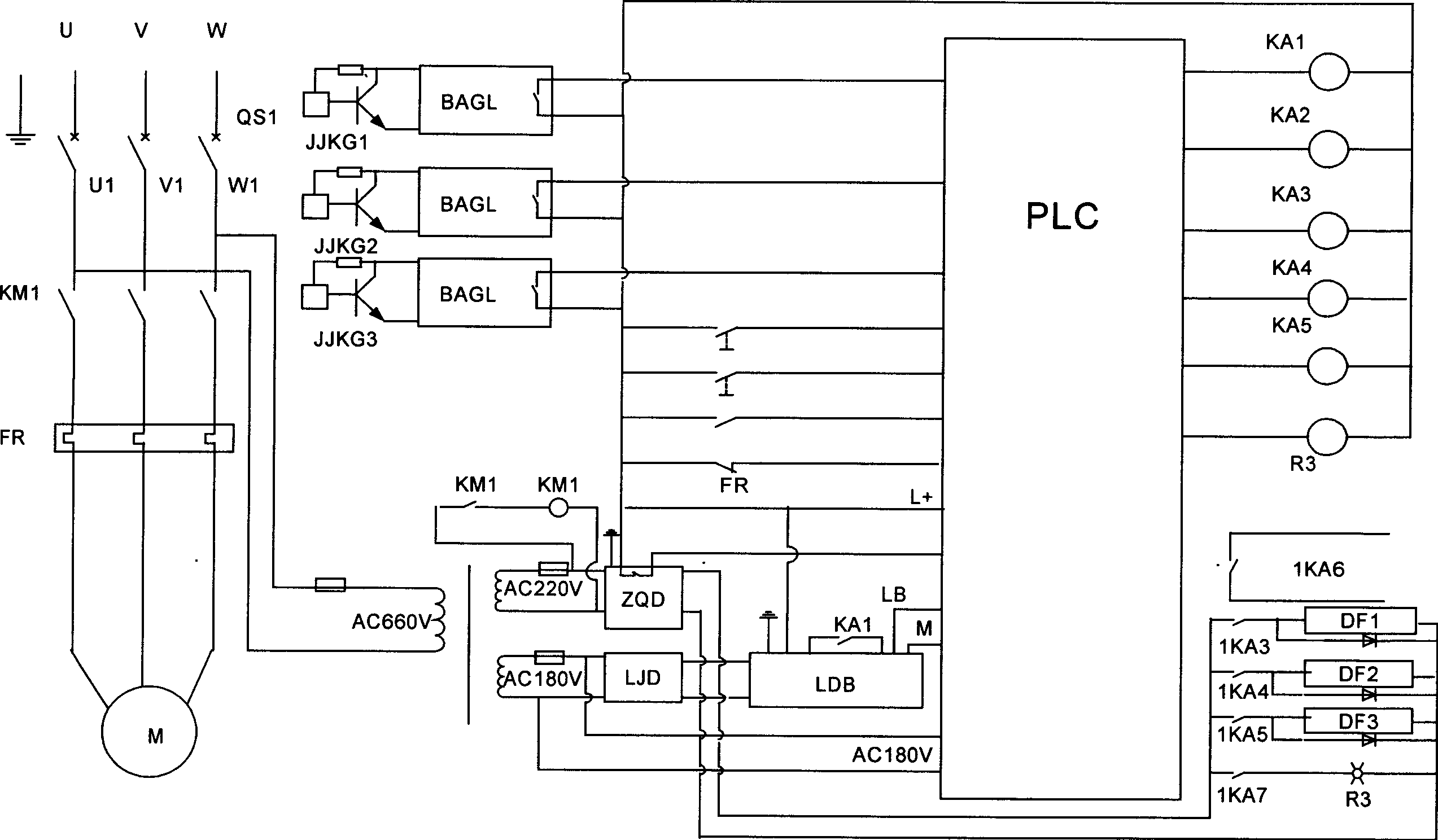

[0011] Explosion-proof electromagnetic ball valve 8 adopts two-position two-way electromagnetic ball valve, and the programmable controller adopts PLC of Siemens S7-200 series whose basic unit is CPU224.

[0012] Connect the 660V power supply, the explosion-proof electromagnetic ball valve 8, the power line and the signal line of the proportional pressure valve 9 to the electric control cabinet, and preload and deform the brake spring 16 according to the rated braking torque. The braking force at this time is the rated braking force. When the single-acting oil cylinder 6 was working, the piston rod 21 made the right end of the brake frame final lever triangular plate 17 subject to an upward thrust, which was transmitted to the left and right brake arms 14,18 through the pull rod 15. The force acting from the oil pressure of the single-acting oil cylinder 6 to the left and right brake arms 14 and 18 is the brake release force, and its direction is opposite to the direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com