Substrate placing stage

A carrier platform and substrate technology, applied in the direction of conveyor objects, optics, instruments, etc., can solve problems such as uneven coating, residual pin marks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

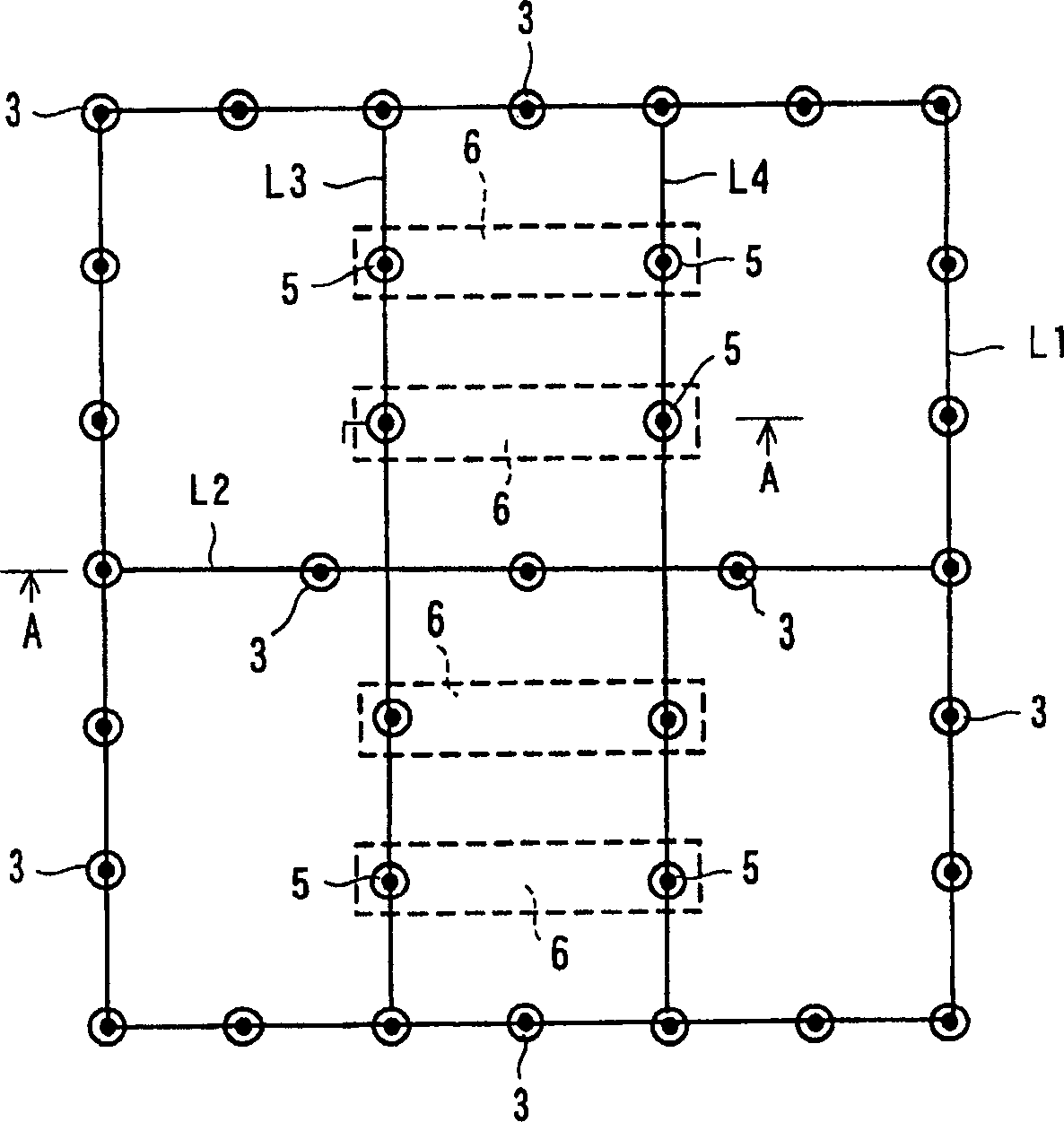

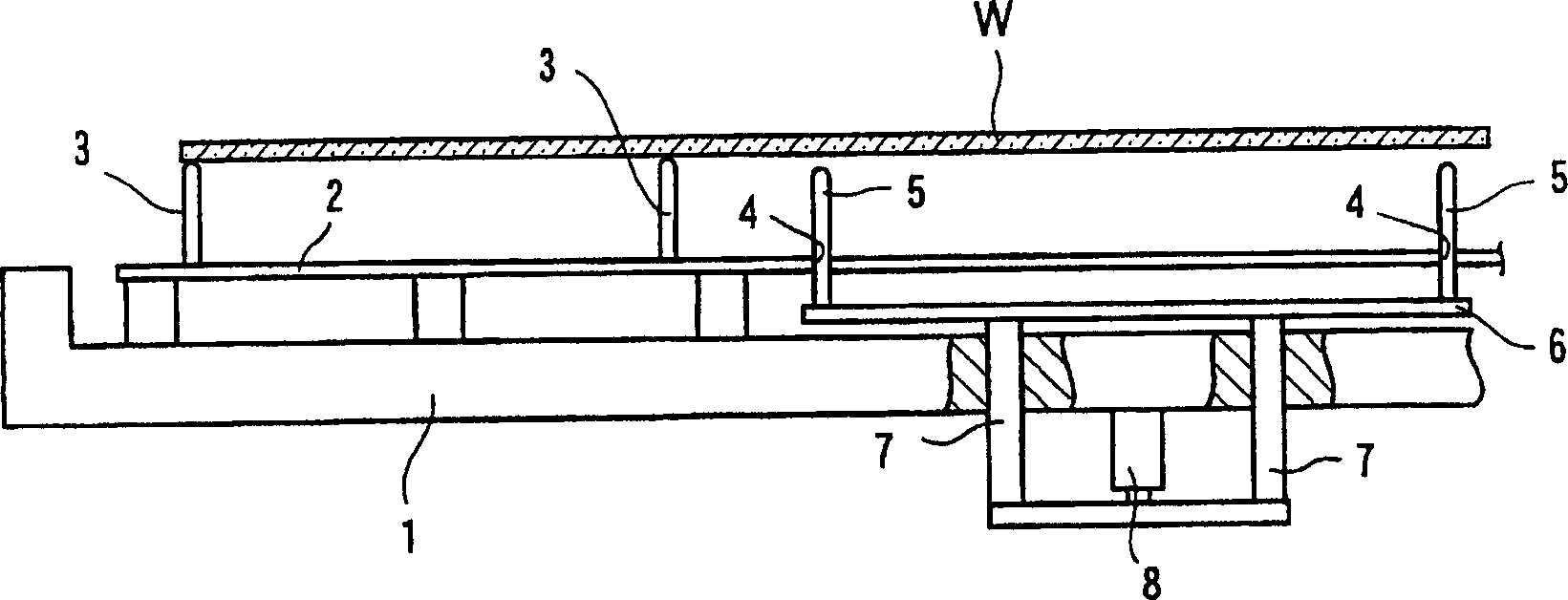

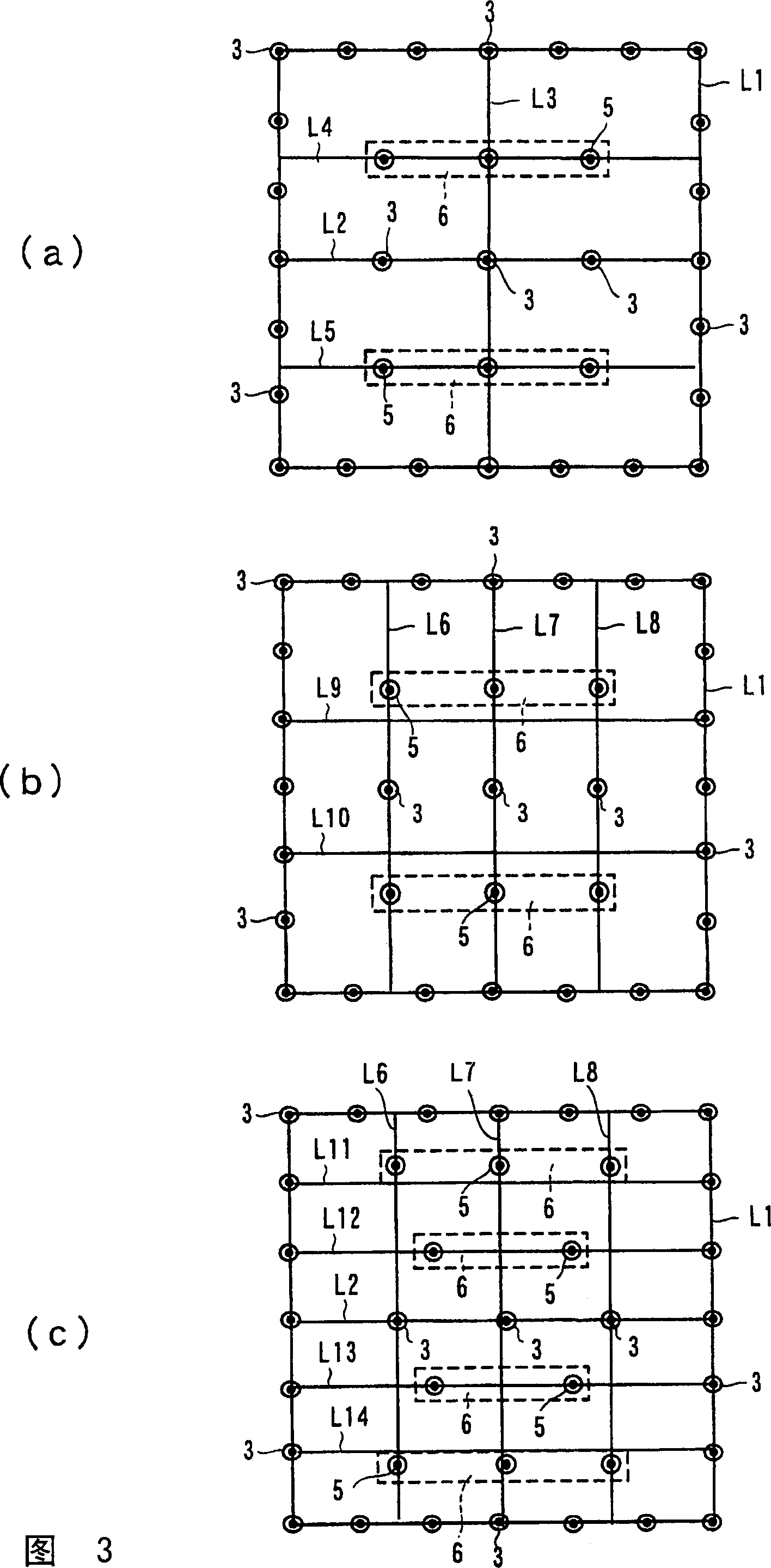

[0033] Embodiments of the present invention will be described below with reference to the drawings. figure 1 It is a top view of the substrate carrying platform of the present invention. figure 2 is along figure 1 An enlarged cross-sectional view of the main part of the line A-A.

[0034] This substrate stage is used, for example, in a process of drying a resist liquid or the like applied on a large glass substrate under reduced pressure.

[0035] The substrate supporting platform is a relatively thin substrate supporting platform installed on the base 1 , and a plurality of fixing pins 3 are installed on the supporting plate 2 . The fixed pin 3 is arranged at a position overlapping the outer peripheral edge L1 outside the effective area of the large substrate W placed on the substrate stage in a plan view, and is also arranged at a position where the large substrate W is cut into two parts. At the position where the scheduled cutting line L2 overlaps.

[0036] On the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com