Method for rolling cutting cone scrole spring

A scroll spring and manufacturing method technology, which is applied in the production field of truncated cone scroll springs, can solve problems such as difficult spring clearance, inaccurate spacing, and complicated rolling process, so as to achieve convenient rolling and reduce manufacturing difficulty. even gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The rolling method of truncated cone scroll spring can be carried out in the following steps:

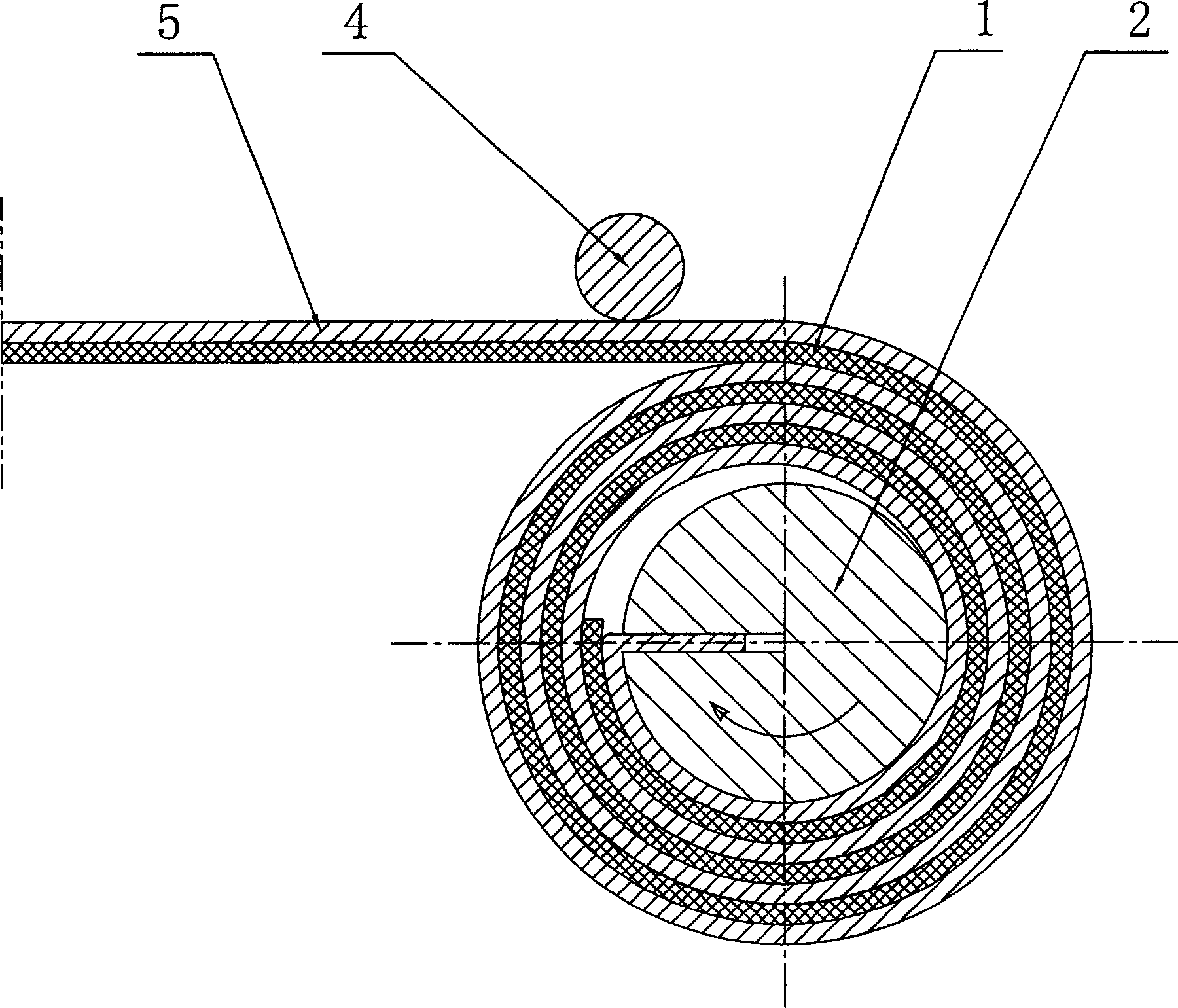

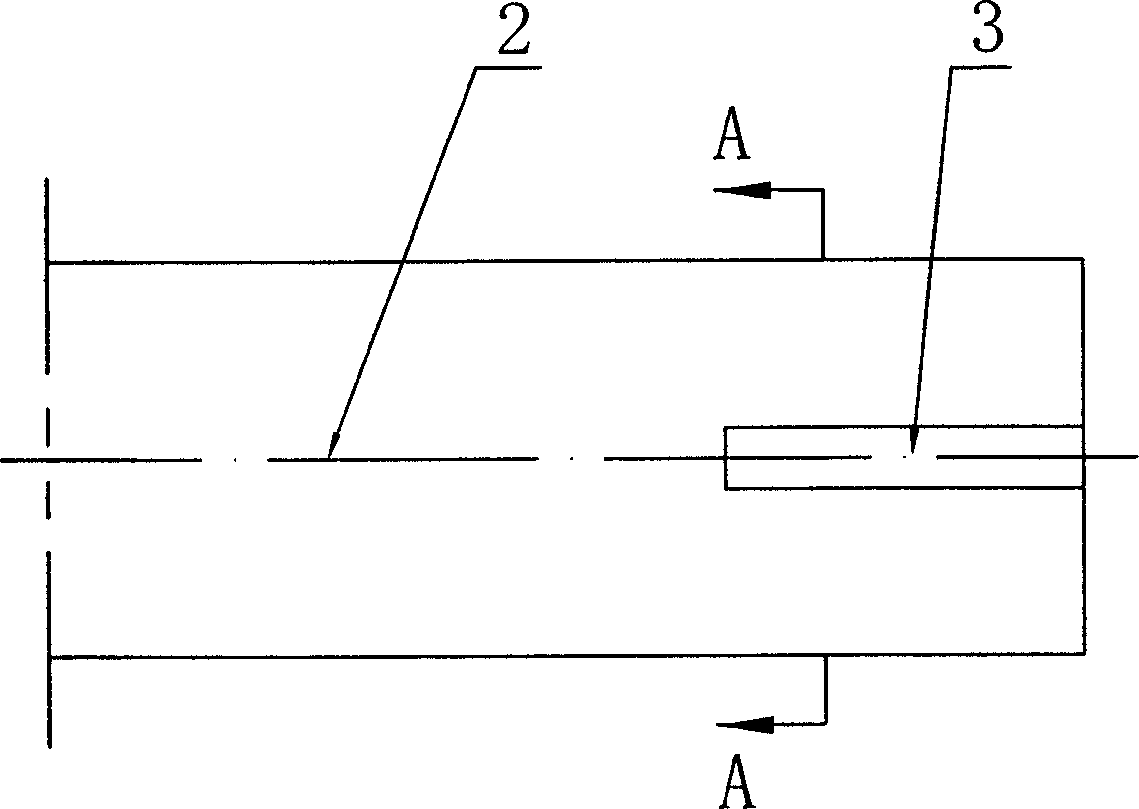

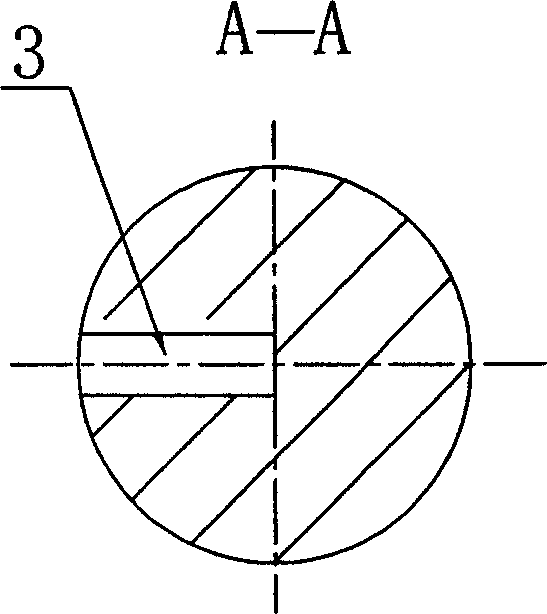

[0015] A) Insert one end of the pre-cut long strip plate into the opening 3 provided by the shaft end of a cylindrical mandrel 2, and make an acute angle between the plate 5 and the mandrel 2, and make an acute angle with the mandrel 2 A stop bar 4 is fixed at a position parallel to and separated from a certain distance, and the distance between the axis of the mandrel 2 and the stop bar 4 is not less than the radius of the scroll spring after the coil is formed;

[0016] B) Turn the mandrel 2 so that the sheet material 5 is attached to the stop bar 4, heat the sheet material between the mandrel and the stop bar, and continuously wind the mandrel 4, and stick the asbestos cardboard 1 against the stop bar 4 during winding. It is wound on the mandrel together on the sheet metal; the purpose of heating is to make the metal sheet soft and easy to bend.

[0017] C) After the roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com