Wet etching device and wet etching method

A wet etching and etching technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of decreased etching quality and low product yield, and achieve the effect of good etching quality and high product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

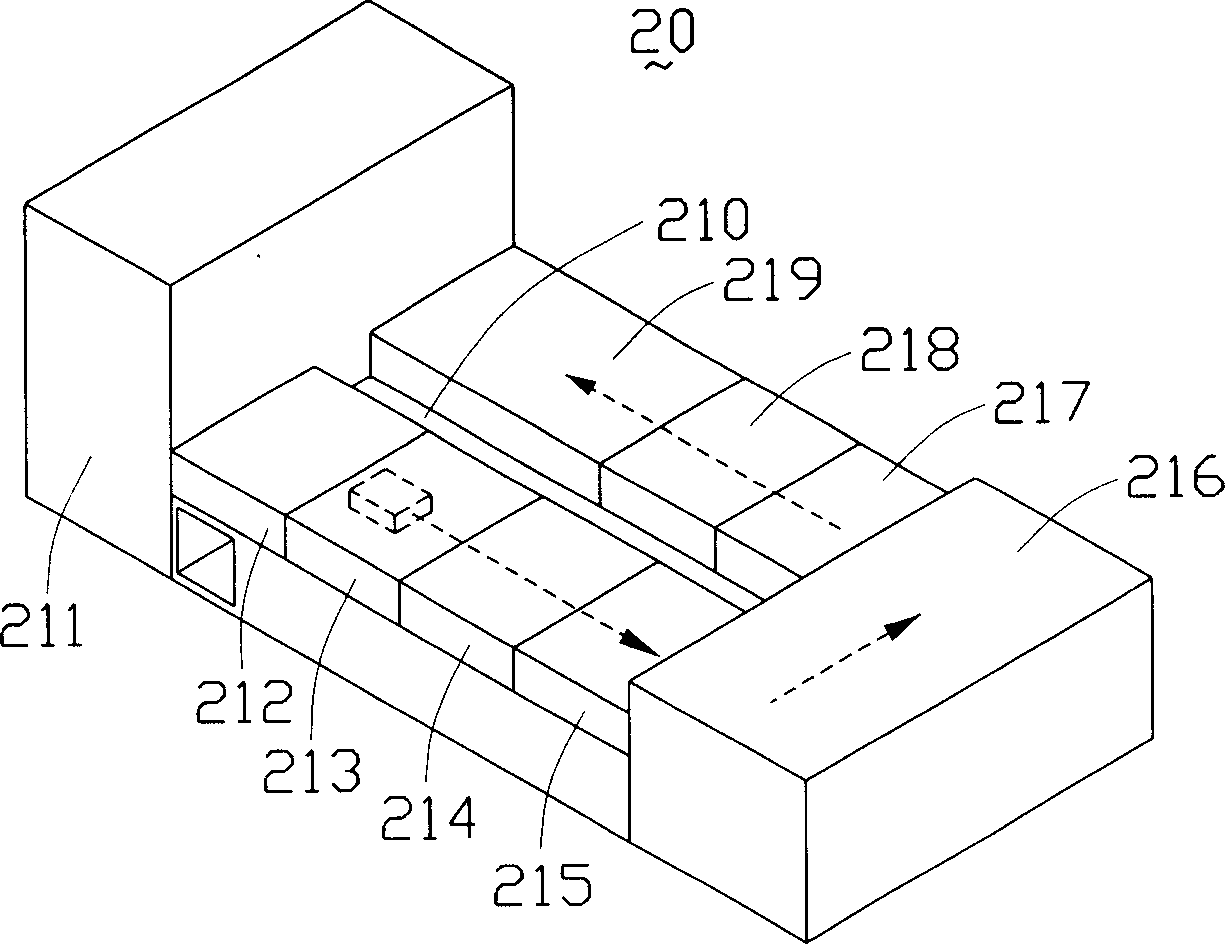

[0020] see figure 2 , is a schematic perspective view of the first embodiment of the wet etching equipment of the present invention. The wet etching equipment 20 includes a substrate carrying chamber 211, a buffer chamber 212, a first etching chamber 213, a cleaning chamber 214, a second etching chamber 215, a wet transfer chamber 216, a rinsing chamber 217, a drying chamber 218, a transfer room 219 and a maintenance area 210 in the center.

[0021] The wet etching equipment 20 is arranged horizontally, and the substrate carrying chamber 211 is respectively connected with the buffer chamber 212 and the dry transfer chamber 219 . The substrate carrying chamber 211, the buffer chamber 212, the first etching chamber 213, the cleaning chamber 214, the second etching chamber 215, the wet transfer chamber 216, the rinse chamber 217, the drying chamber 218 and the dry transfer chamber 219 are connected end-to-end in order and surround in a rectangular shape. The maintenance area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com