Method for fabricating direction matched magnet in profiled square inner diameter of annular ferrite magnetic pole, and structure

A ferrite magnet and manufacturing method technology, applied in the manufacture of permanent magnets, inductors/transformers/magnets, magnetic circuits, etc., can solve the problems of insufficient magnetic force, easy breakage, good magnetic properties, etc., to improve the surface magnetic flux density, Strong acid and alkali resistance and moisture resistance, and the effect of improving the magnetic field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

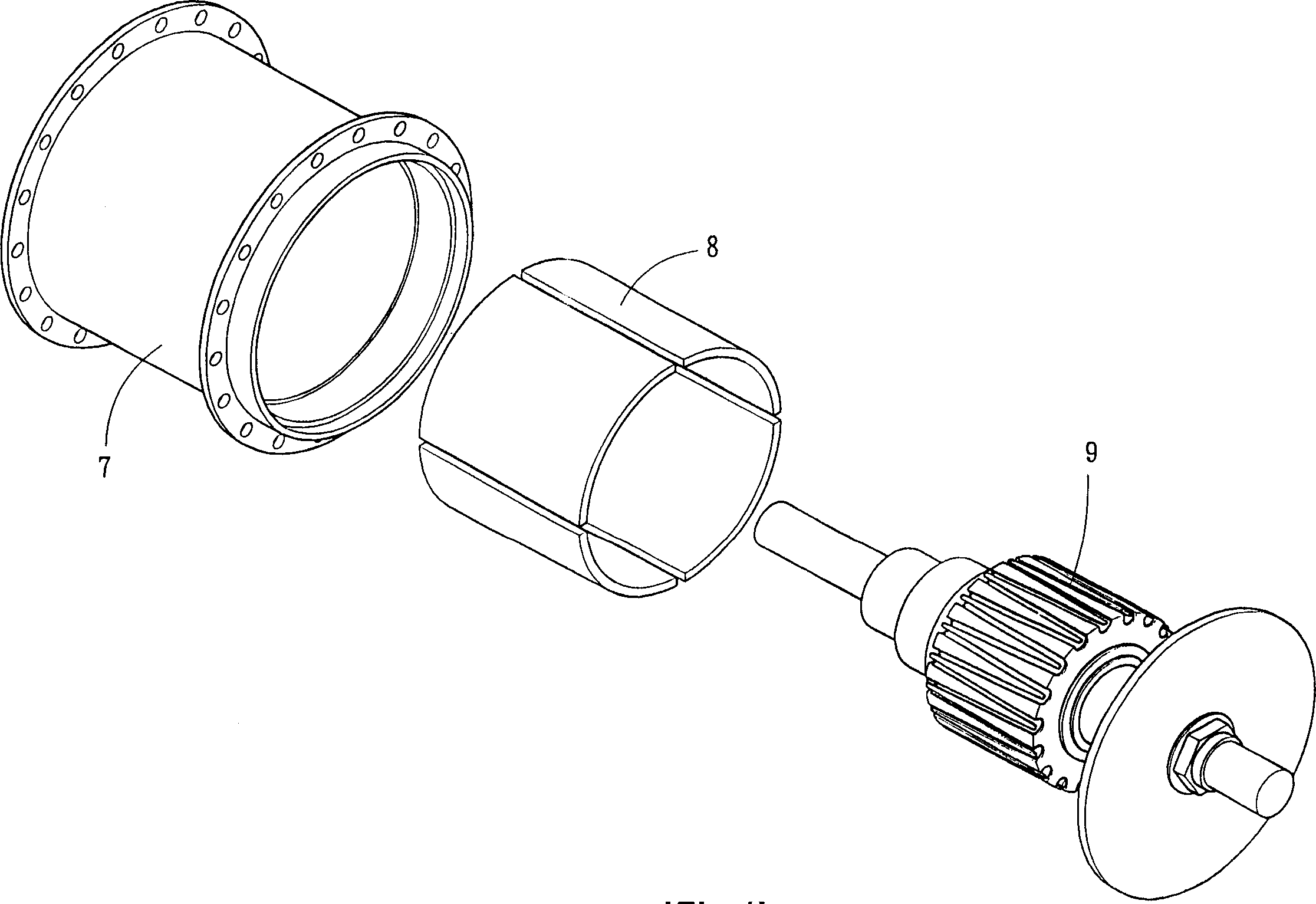

[0053] The technical features and achieved effects of the present invention will be described in detail below with reference to the embodiments and accompanying drawings, so that readers can have a deeper understanding of the present invention.

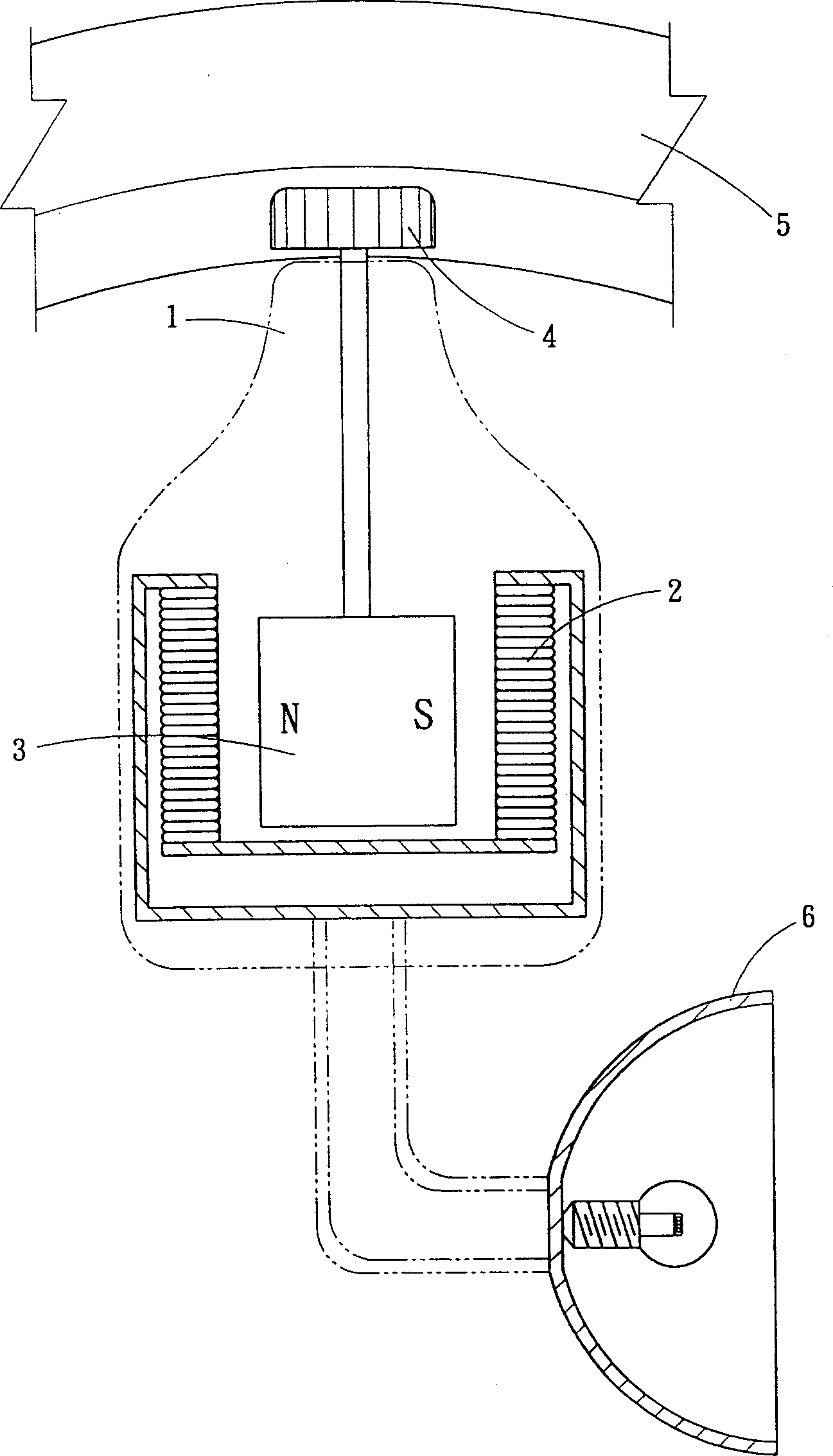

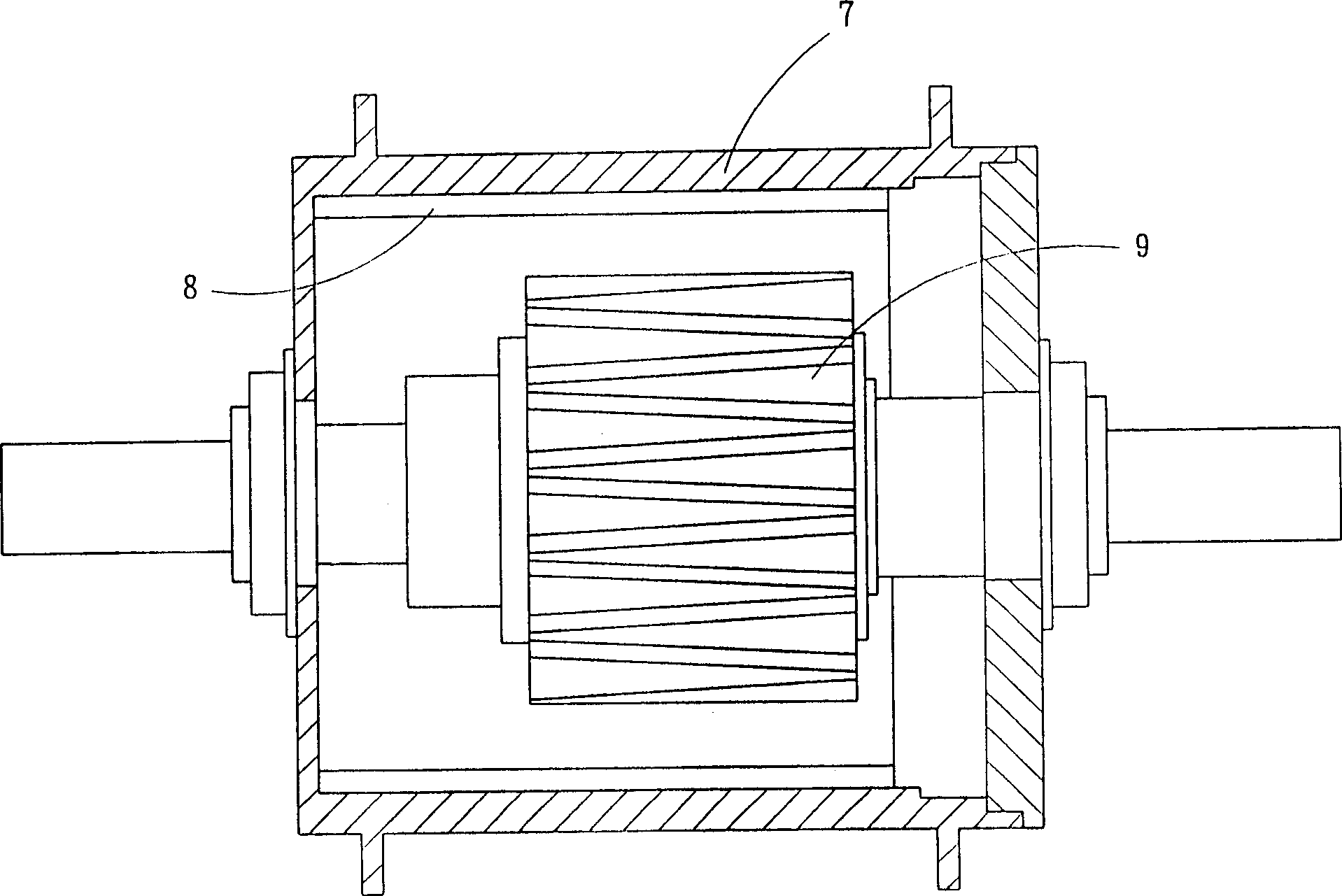

[0054] Such as Figure 4-Figure 6 As shown, the manufacturing method of the ring-shaped ferrite magnet of the present invention with different inner diameter alignment magnets is aimed at brushless DC motors and bicycle hub-type generators (Hub-Dynamo) or other outer-rotating generators. The permanent magnets used in the outer rotor provide an innovative manufacturing method and improved structure of the ring-shaped ferrite magnets with different square inner diameter alignment magnets. The processes include: powder process, granulation, stamping and alignment, sintering, Grinding and magnetization detection steps are characterized in that:

[0055] After the granulated magnetic powder 50 is filled into the mold set having an annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com