Auto-adaptive driving and sensing device for electric motorcycle

A technology for electric motorcycles and sensing devices, applied in motorcycles, electric vehicles, electric devices, etc., can solve the problems of low motor efficiency, inaccurate control, excessive battery current, etc., and achieve high precision and accurate signals. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

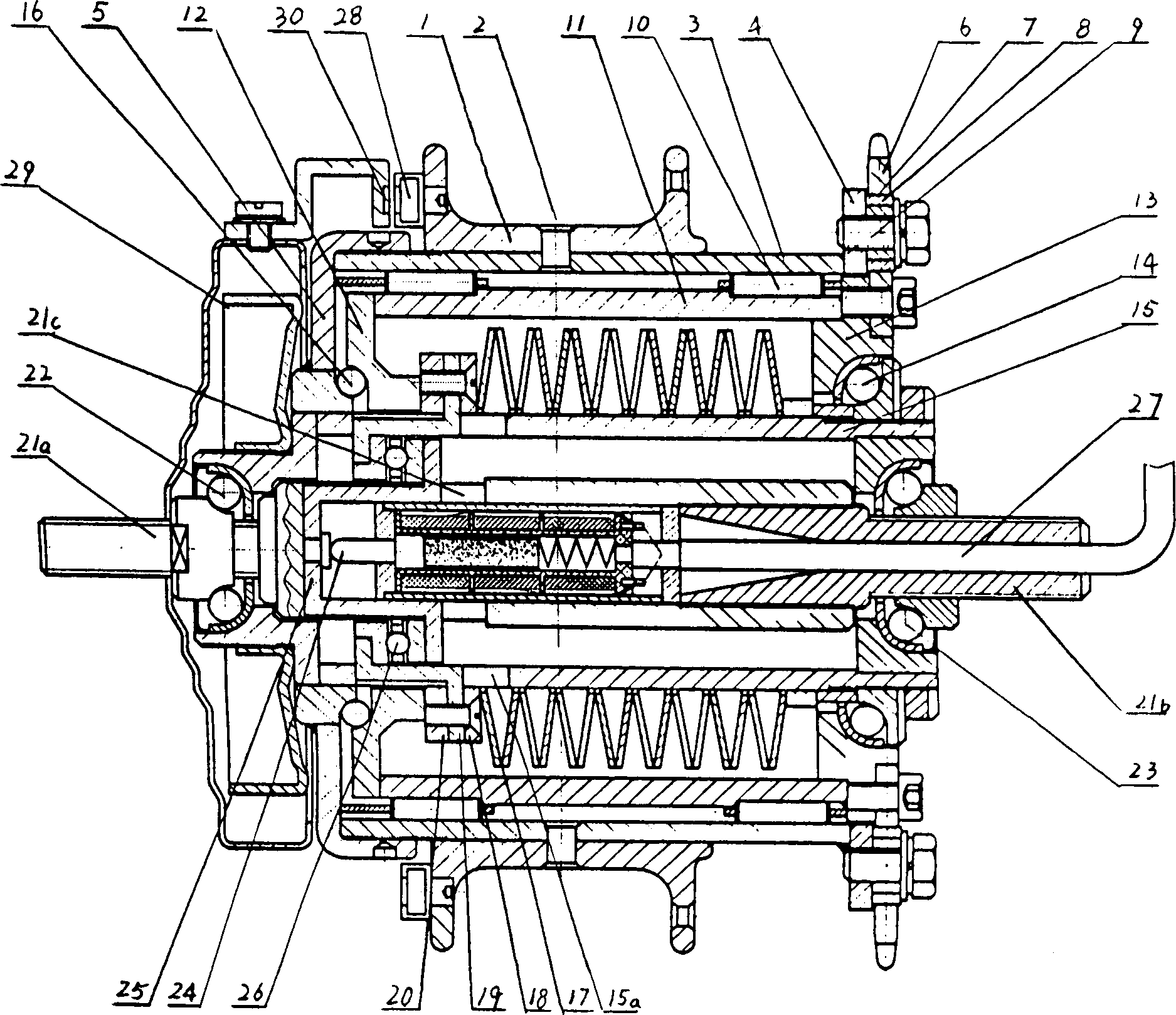

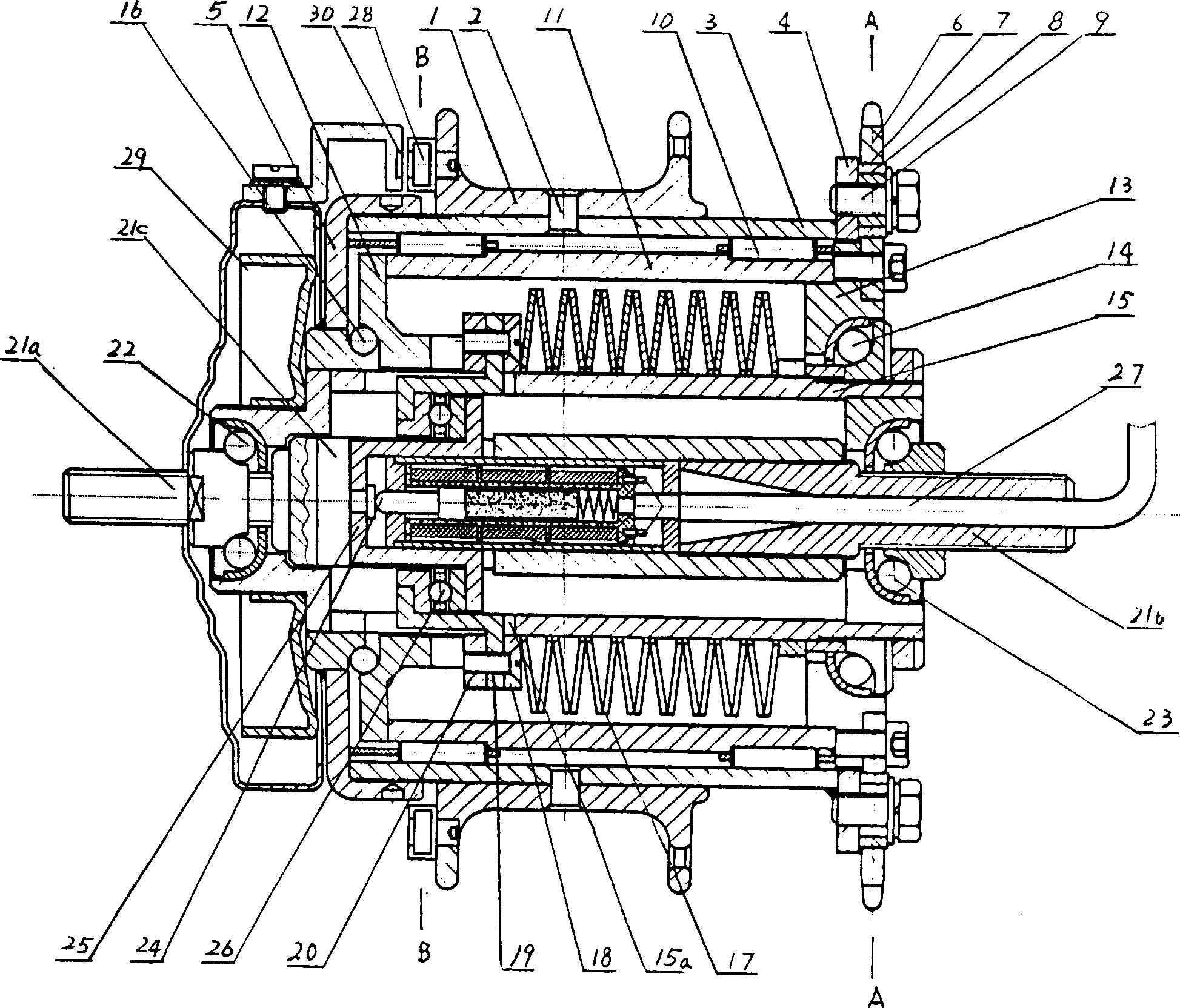

[0020] Embodiment 1: see figure 1 , figure 2 , the rear hub 1 is connected to the middle part of the large sleeve 3 with the fixed pin 2, the sprocket connection plate 4 is fixedly connected to the right end of the large sleeve 3, and the end cover 5 is connected to the left end of the large sleeve 3;

[0021] Use screw 9 to pass through the center hole of the roller 8 in the circular arc strip groove 7 on the sprocket 6, and the sprocket 6 is connected to the sprocket connection plate 4; When the rear wheel hub speed is inconsistent with the sprocket speed, The roller can slide in the arc groove of the sprocket;

[0022] Install the needle roller bearing 10 in the large sleeve 3, the left end of the inner ring 11 of the needle roller bearing is splined with the left-rotating end face cam 12, and the right end is fixedly connected with the connection plate 13 and the sprocket 6 through screws; A bearing 14 is installed between the connecting plate 13 and the right end of th...

Embodiment 2

[0027] Example 2: see Figure 7 , the spring assembly is a disc spring, and the others are the same as in Embodiment 1. Using the spring assembly as a disc spring can improve the displacement accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com