Method for mounting compressor piston and slipper into cylinder

A cylinder block and compressor technology, applied in the field of compressor manufacturing, can solve the problems of piston falling off, high labor intensity, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

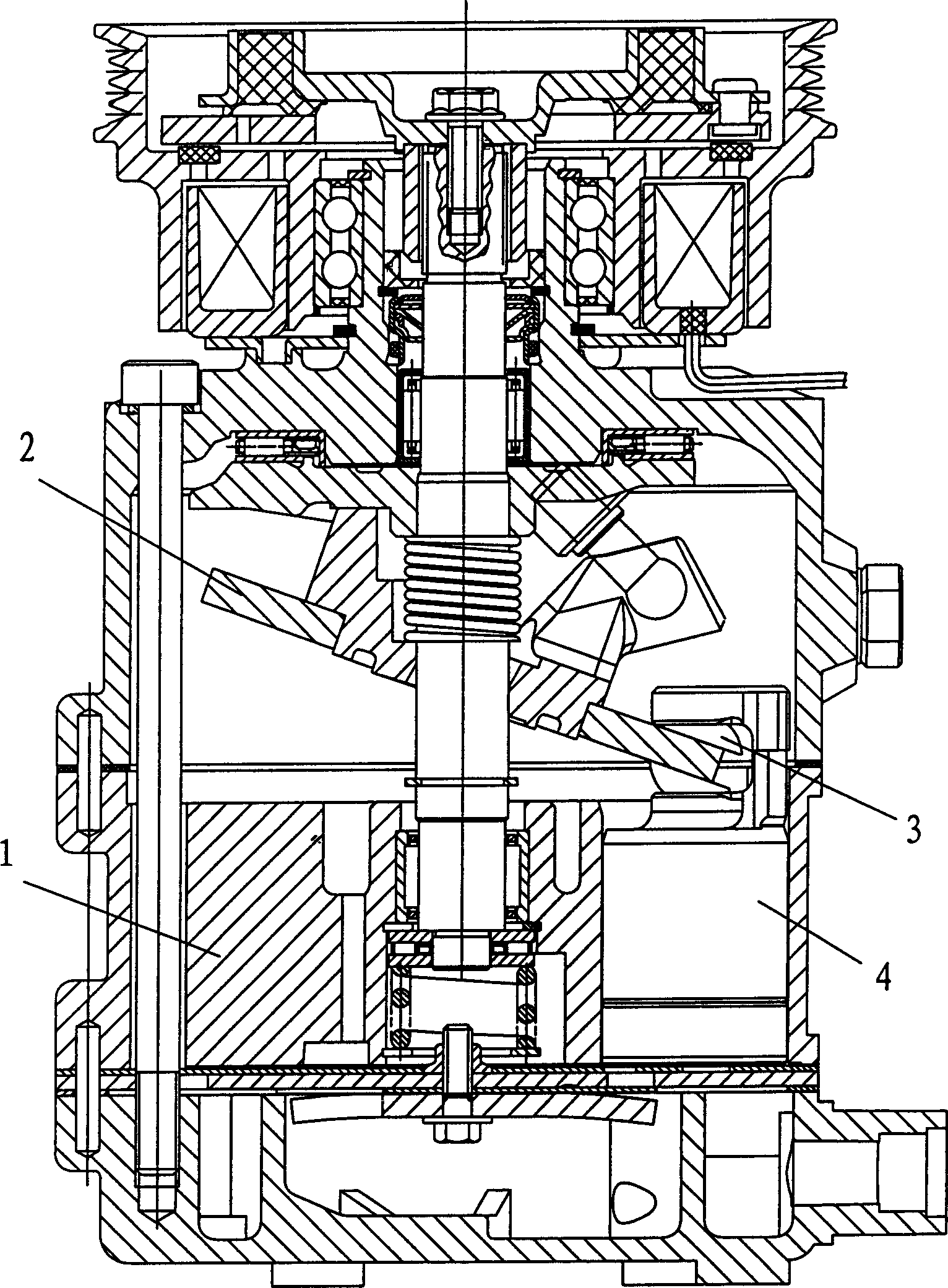

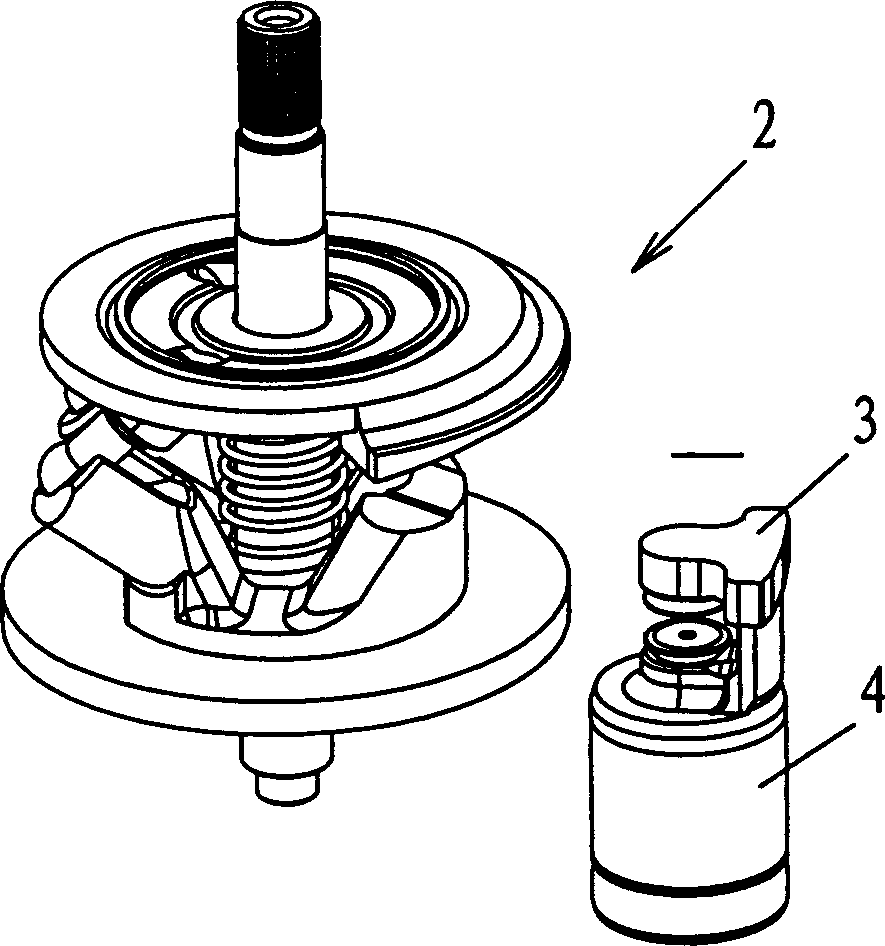

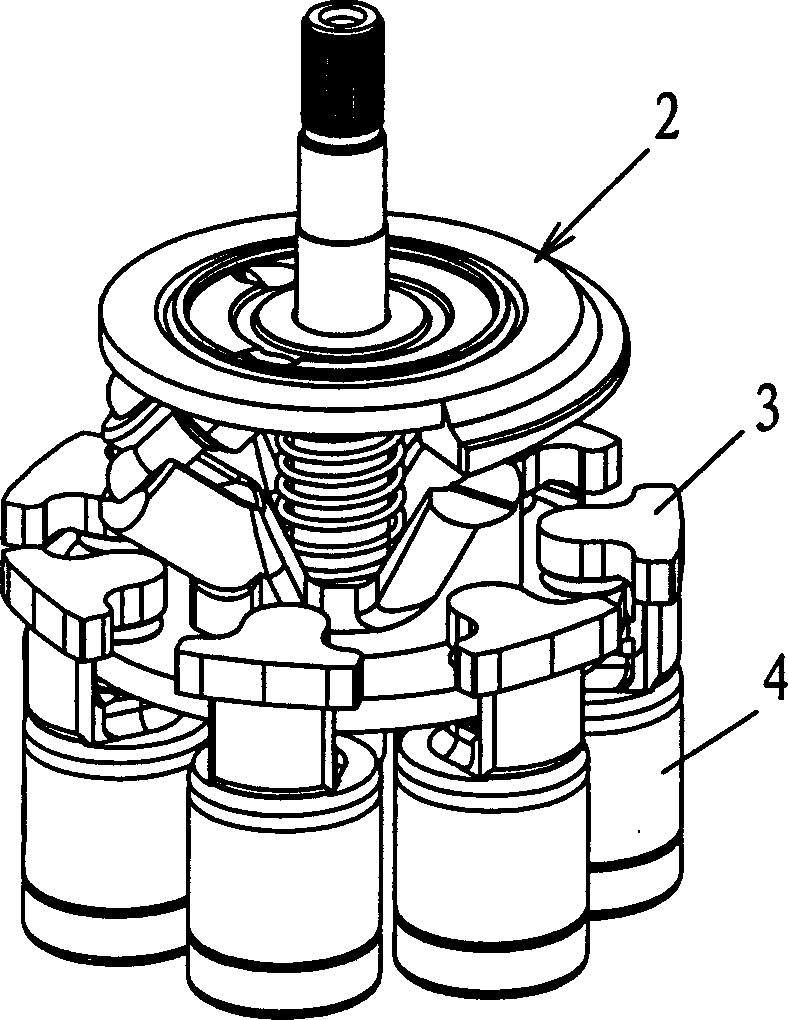

[0023] The present invention utilizes the characteristic that the swash plate of the variable displacement compressor has a variable angle, and the piston and the sliding shoe are loaded into the cylinder body at one time by inclining the swash plate at a certain angle.

[0024] like Figure 7 As shown, the cylinder block 1 is first placed on a rotatable turntable 21, and the main shaft swash plate component 1 is lifted to a certain position directly above its installation position through a lifting and supporting mechanism (not shown in the figure). , so that a certain space is reserved between the swash plate 20 and the cylinder block 1, and the swash plate 20 is in a nearly horizontal position due to the elastic force of the spring.

[0025] like Figure 8 As shown, then turn the swash plate 20 to a certain angle along the deflection direction of the swash plate. At this time, the maximum space generated by the lifting of the cylinder block and the deflection of the swash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com