Variable valve lift control system for a combustion engine with underneath camshaft

A valve lift, internal combustion engine technology, applied in the direction of valve devices, mechanical equipment, engine components, etc., can solve problems such as comfort damage, and achieve cost-effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

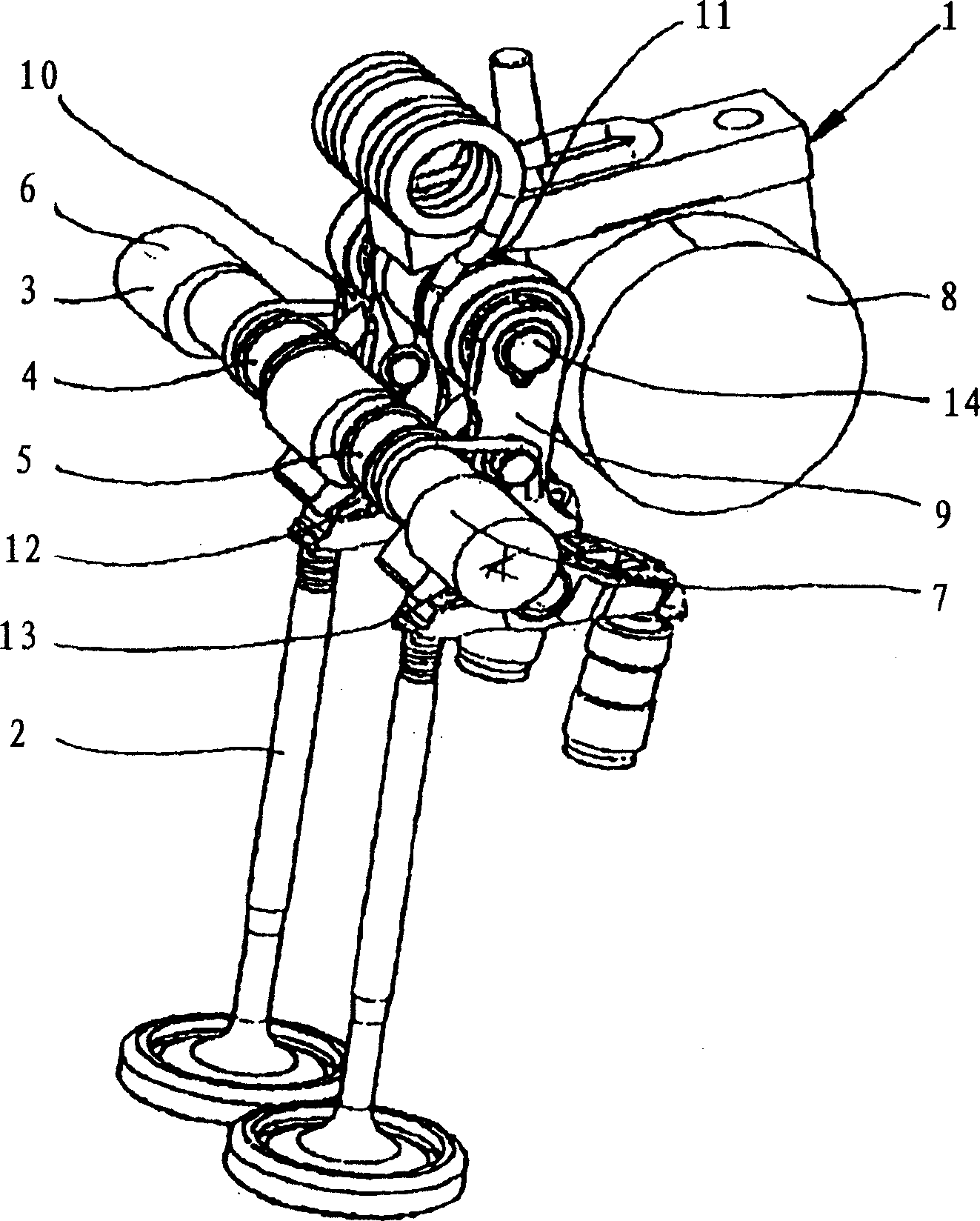

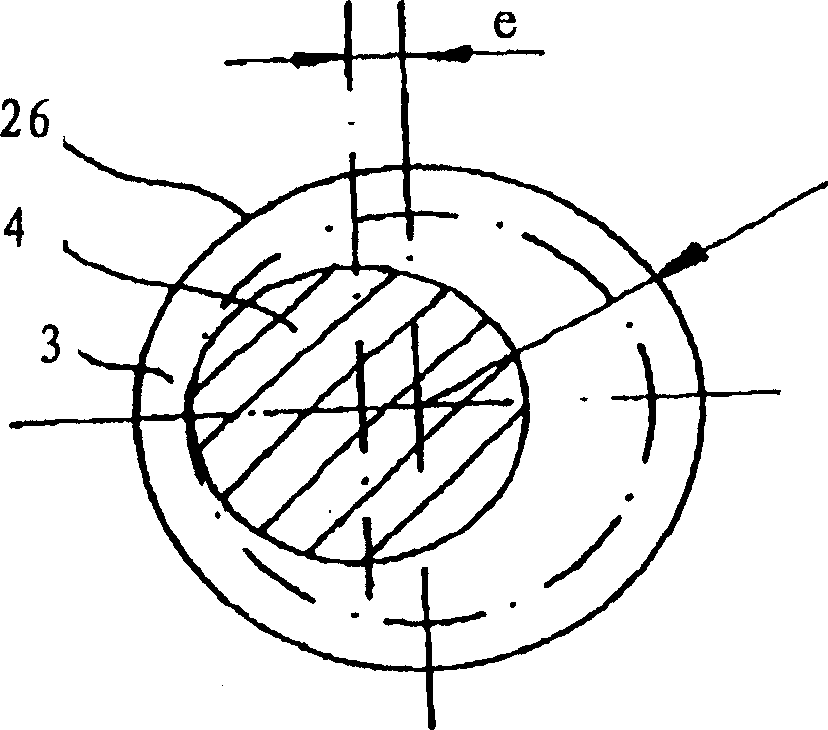

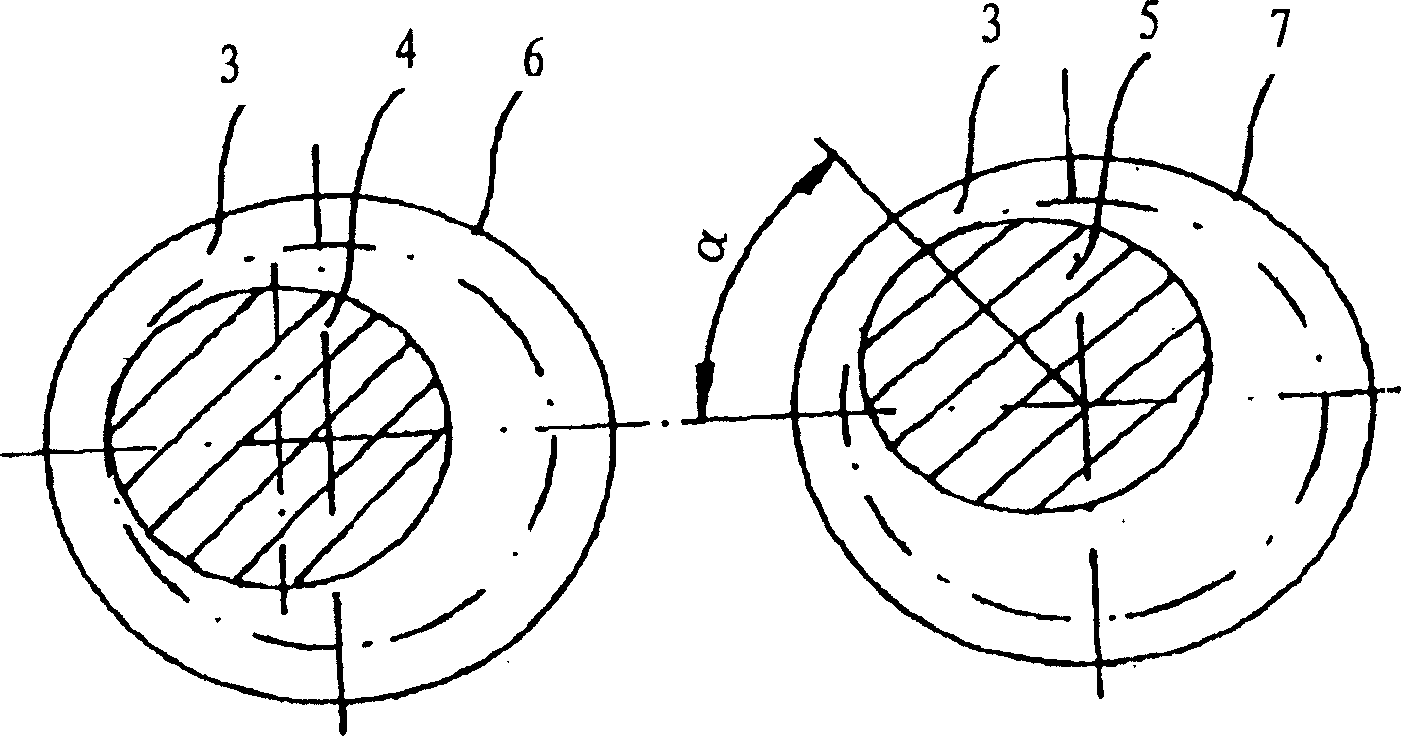

[0119] figure 1 shows a valve lift system for variable lift adjustment of the gas exchange valve 2 of a valve lift device 1 presenting a rotatable eccentric shaft 3 comprising several eccentrics 4, 5, where all possible contours of the eccentrics 4, 5 lie within a circle formed by means of the outer diameters of the bearings 6, 7 of the eccentric shaft 3 ( figure 2 ). The eccentric shaft 3 can be inserted through a through-bore in the material of the cylinder head (not shown) and engages directly in the through-bore in the cylinder head. Thereby, the eccentric shaft 3 can be mounted as an insertable eccentric shaft 3 from one of the front walls of the cylinder head. The eccentric shaft 3 can be embedded in a separate housing, which is connected to the cylinder head. In the housing, the eccentric shaft 3, the rocker levers 9, 10, the camshaft 8 and the slotted connecting rod 11 are inserted as pre-assembled units. It is also possible to engage the eccentric shaft 3 by mean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com