Miniaturized integrated equipment of drinking water filling machine

A complete set of equipment, filling machine technology, applied in bottling machines, packaging, bottle filling, etc., can solve problems such as loud noise, unsuitable living environment, equipment that cannot meet actual use requirements, etc., to achieve streamlined pipeline structure, save cost, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

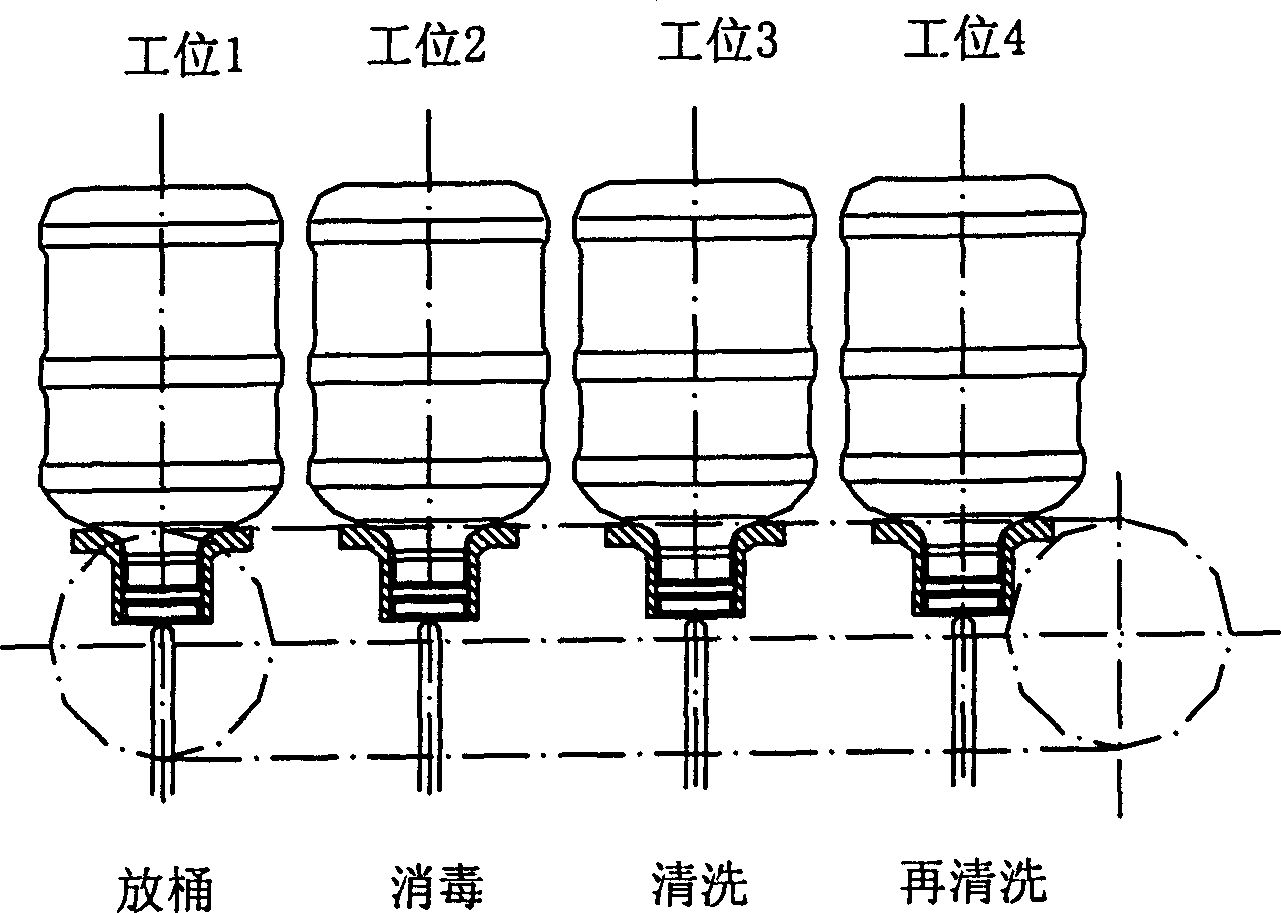

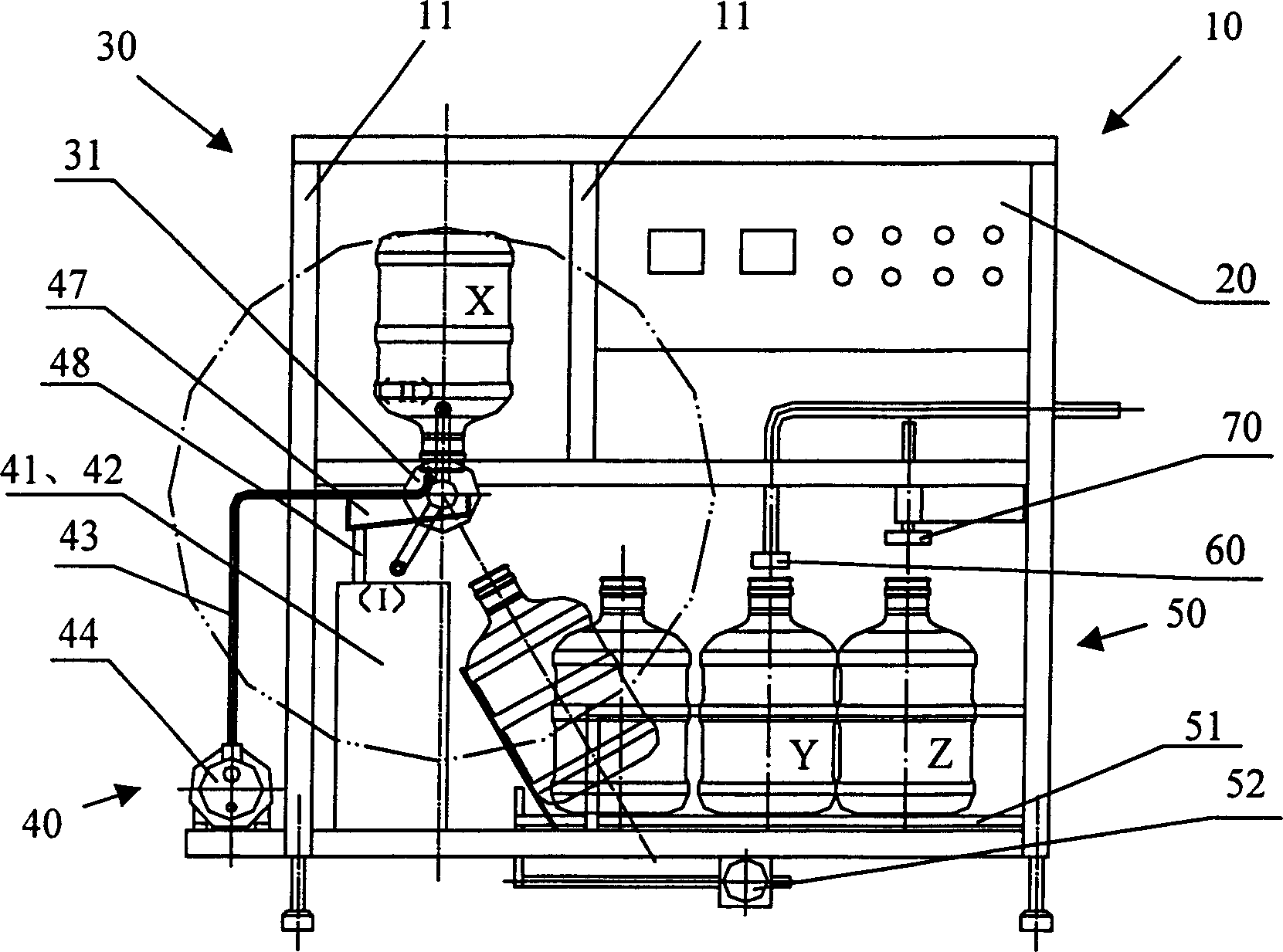

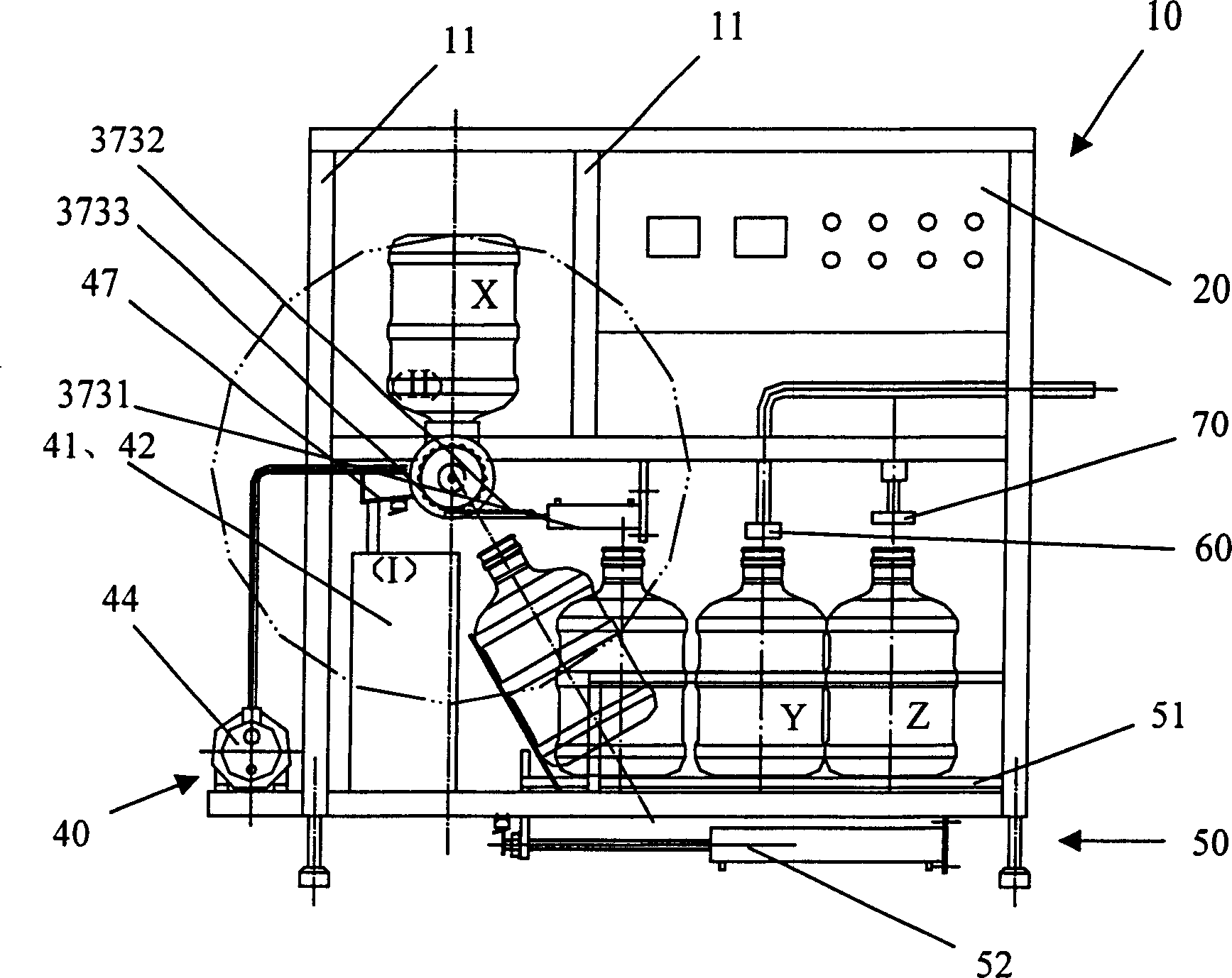

[0054] See figure 2 and image 3 As shown, this is a schematic structural view of the miniaturized complete set of drinking water filling machine of the present invention. The miniaturized complete set of the drinking water filling machine of the present invention comprises a frame 10, an electric control cabinet 20 arranged on one side of the upper part of the frame 10, and a drinking bucket turning mechanism 30 located on the other side of the upper part of the frame 10, which is arranged on the machine The lower part of the frame 10 and the disinfection and cleaning mechanism 40 located below the drinking bucket turning mechanism 30, the bottle pulling mechanism 50 that is arranged below the frame 10 to promote the movement of the drinking bucket, and the opposite side that is arranged at the bottom of the frame 10 and is positioned at the side of the disinfection and cleaning mechanism 40 The drinking bucket carries out the filling mechanism 60 and the capping mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com