Zero-discharge non-pollution combined production process for ecological paper pulp

A production process and zero-emission technology, which is applied in the field of pulp manufacturing, can solve problems such as emissions and damage to the living environment, and achieve the effects of reducing production costs, saving plant raw materials, and achieving environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

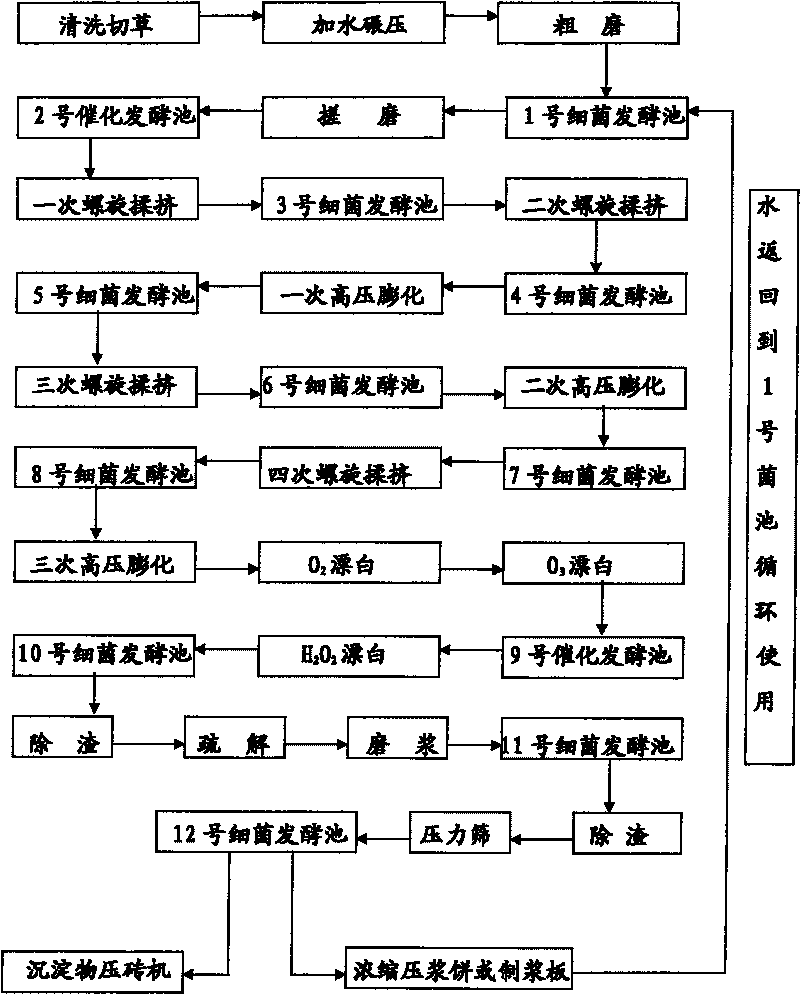

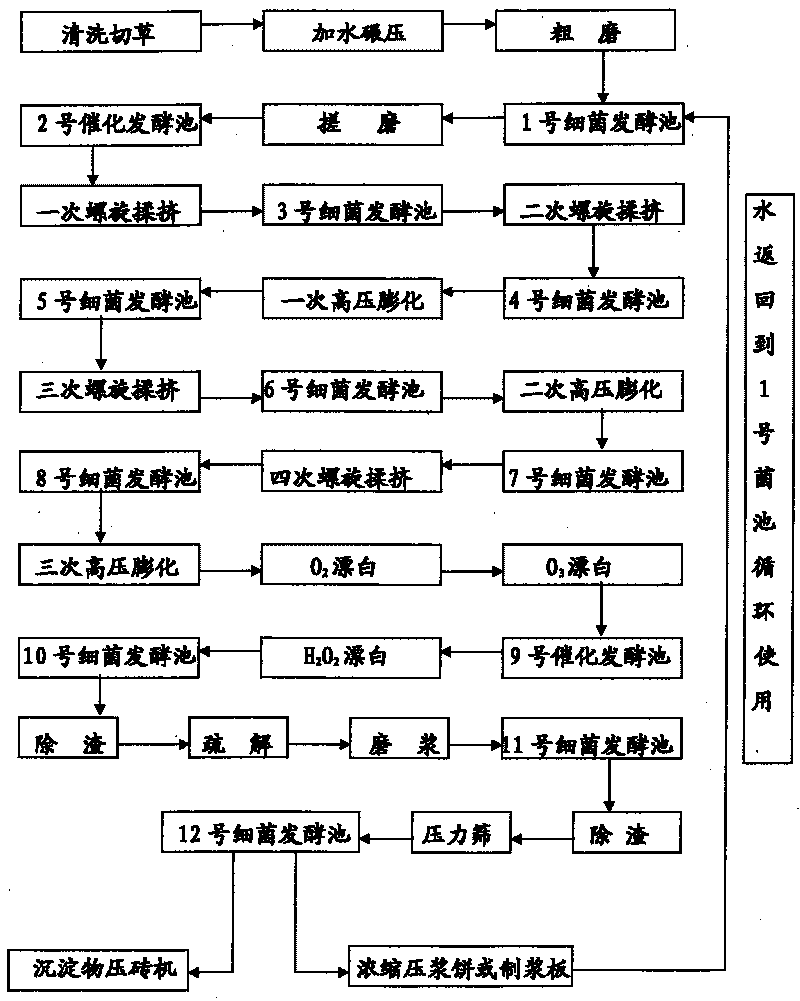

Image

Examples

Embodiment Construction

[0019] The specific implementation, process, features and effects of the zero-emission and pollution-free ecological pulp combination production process proposed by the present invention are described in detail below.

[0020] There are many plant raw materials that can be produced by applying the production process of the present invention, including various woods such as coniferous wood and broad-leaved wood, branches of trees, leftover sawdust of wood products, sawdust, wood blocks, etc.; including straw, wheat straw, reed, sugar cane Various grass plants such as slag and bamboo; including sandalwood bark, mulberry bark, hemp, cotton and other plant bast and fibers, are all good raw materials for ecological pulp making.

[0021] The present embodiment takes reed as raw material and specifies that the production process is as follows in conjunction with the accompanying drawings:

[0022] Source of raw materials: Biochemical indicators of reeds produced in Panjin:

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com