Combined foundation of backstay type machinery apparatus

A technology of mechanical equipment and combined foundations, which is applied in infrastructure engineering, construction, etc., and can solve the problems of long production cycle, resource waste environment, and long construction cycle in cold regions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

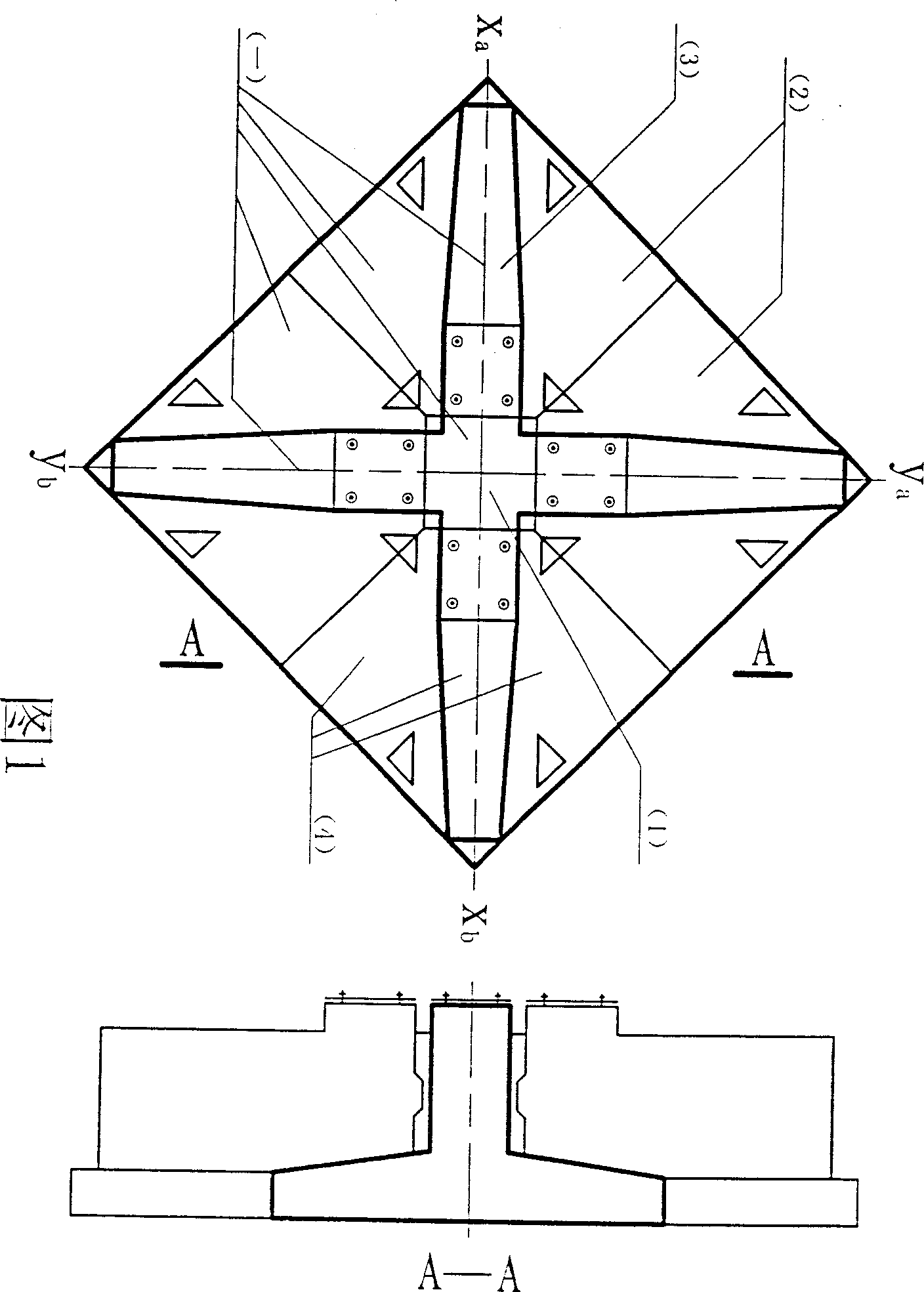

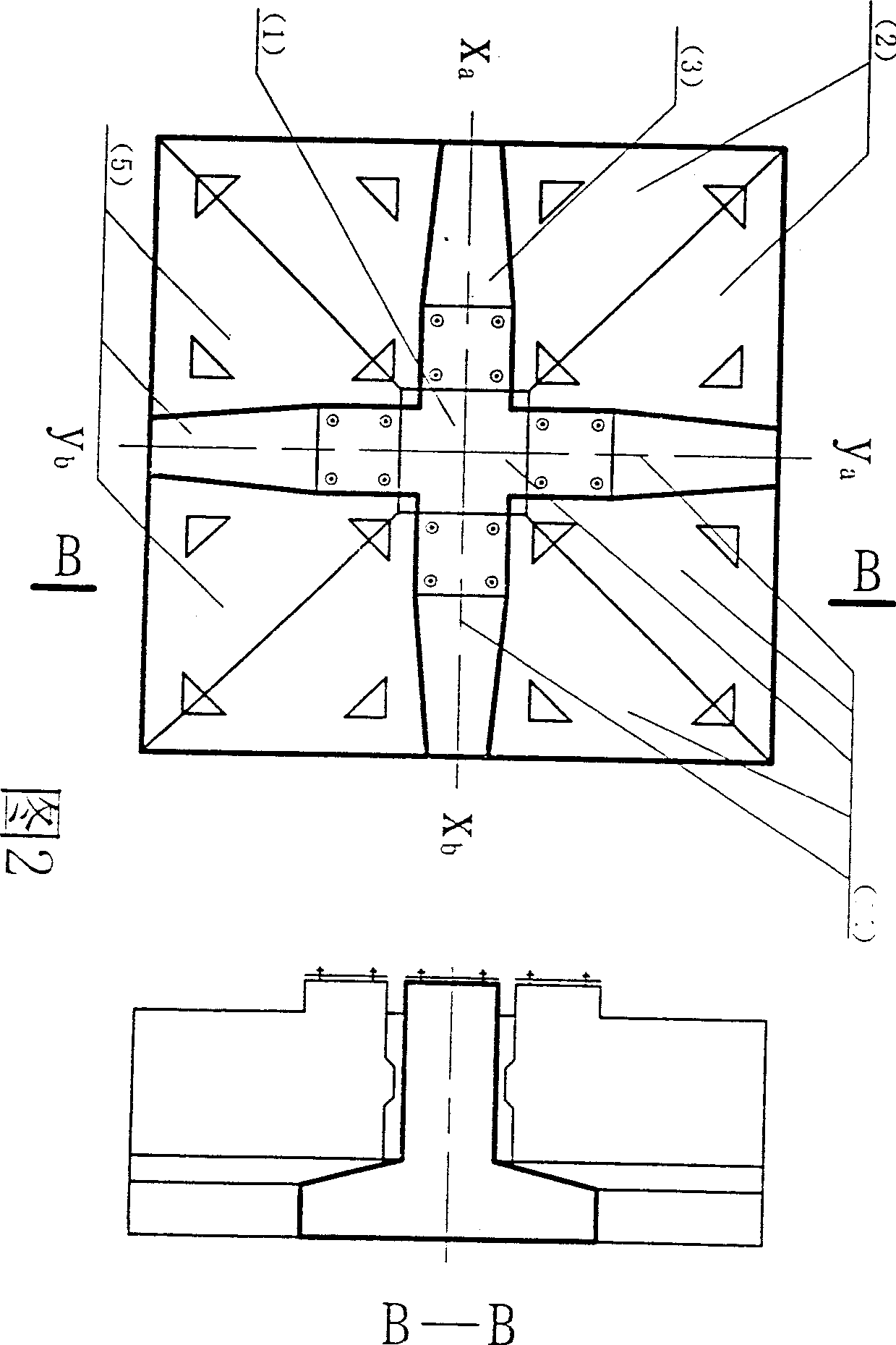

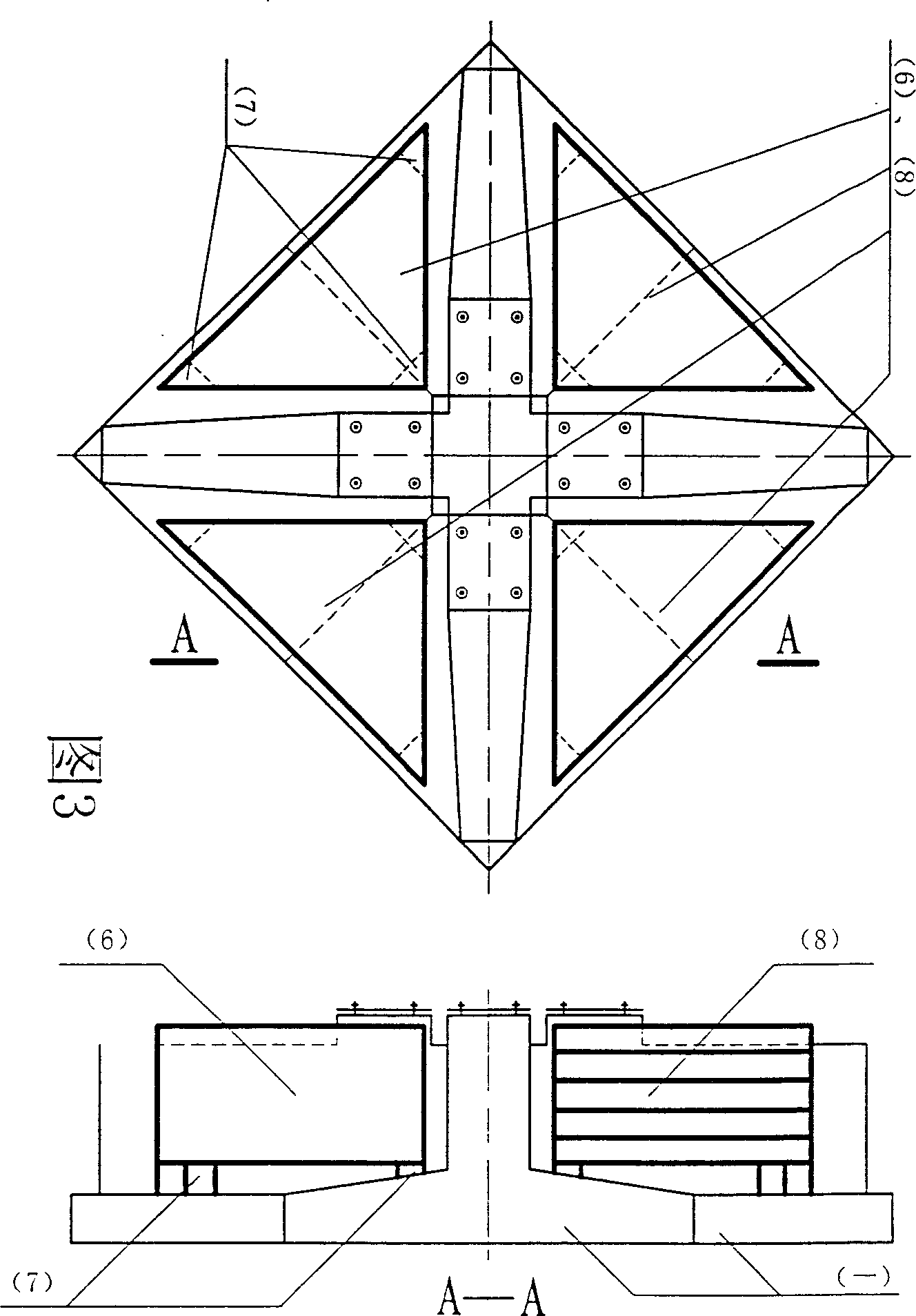

[0083] The beam-slab structure (1) of the concrete prefabricated component combined foundation of the mast-type mechanical equipment described in Fig. 1 includes one central component (1) of the concrete prefabricated basic structural component, and four integrated components (4) horizontally combined. The mast-type mechanical equipment concrete prefabricated component combined foundation beam-slab structure (2) described in Fig. 2 includes a concrete prefabricated foundation structural component central component (1) and four integrated components (5) horizontally combined. After the foundation beam-slab structure (1) or (2) is configured with concrete prefabricated gravity parts (6) or (8) or bulk material gravity parts (12), or configured with concrete prefabricated gravity parts (9) or (11), It constitutes the whole structural gravity main body of the combined foundation of concrete prefabricated components of mast type mechanical equipment. As shown in Figures 3, 4, 5, 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com