Method for precisely measuring incident angle by means of laser feedback and application thereof

A laser feedback and incident angle technology, applied in the field of optical detection, can solve the problems of increased instrument cost and low precision, and achieve the effects of reduced production and use costs, high precision, and good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

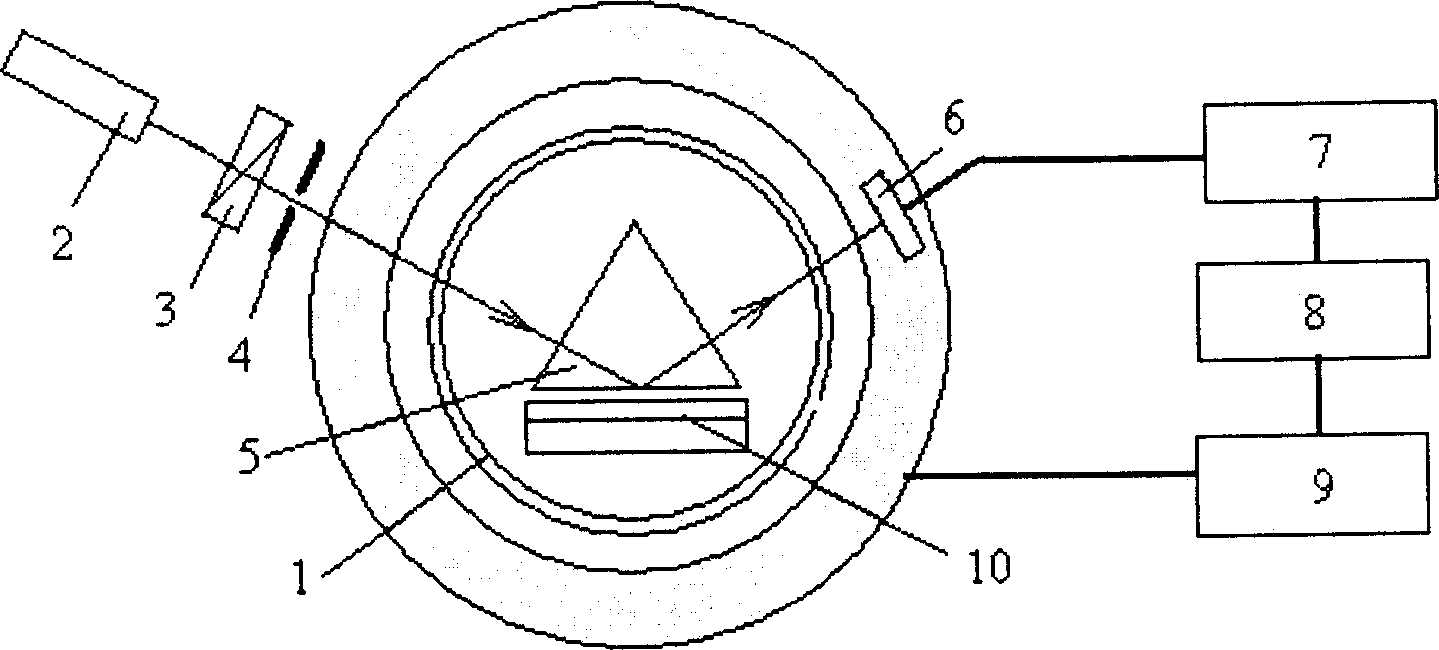

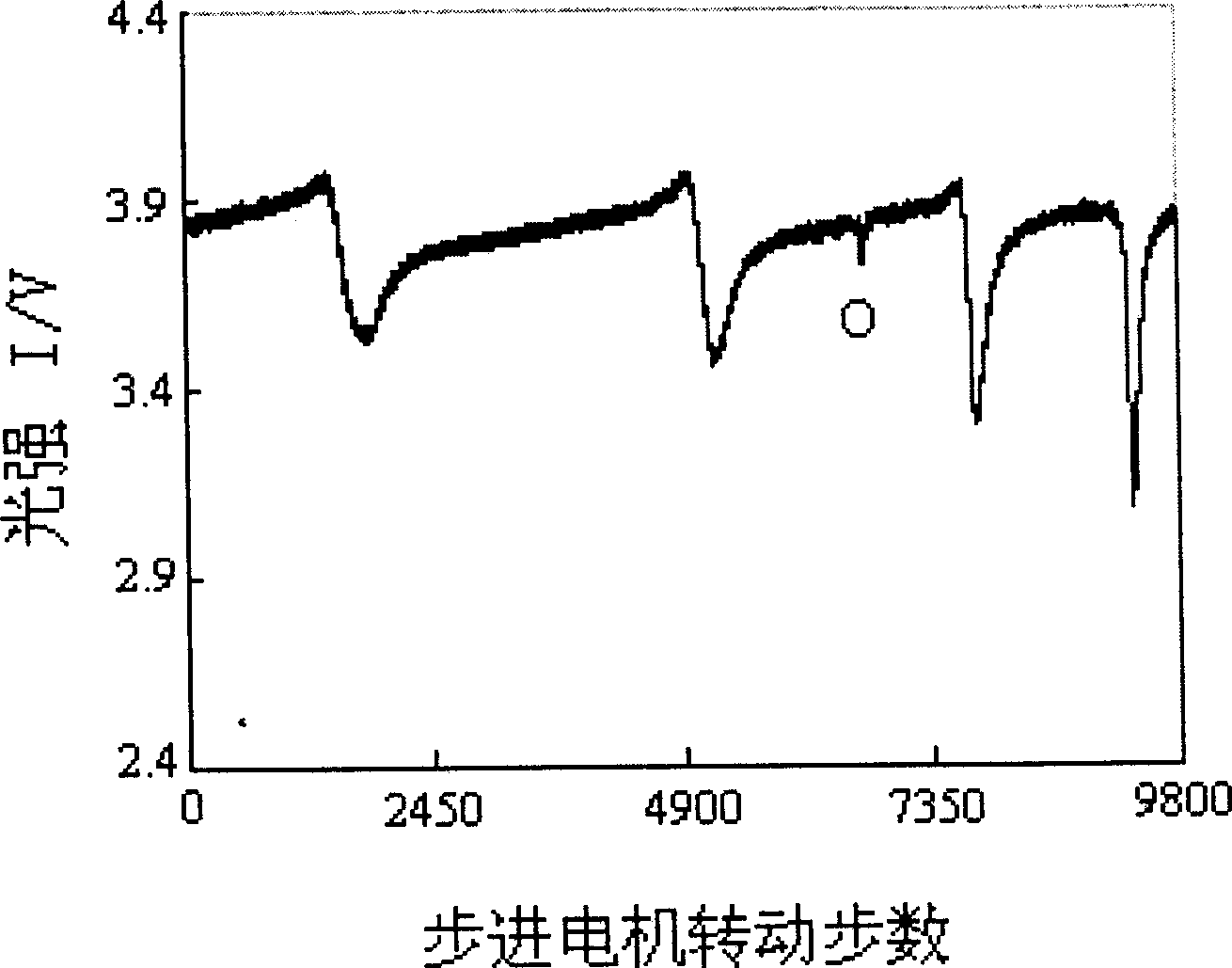

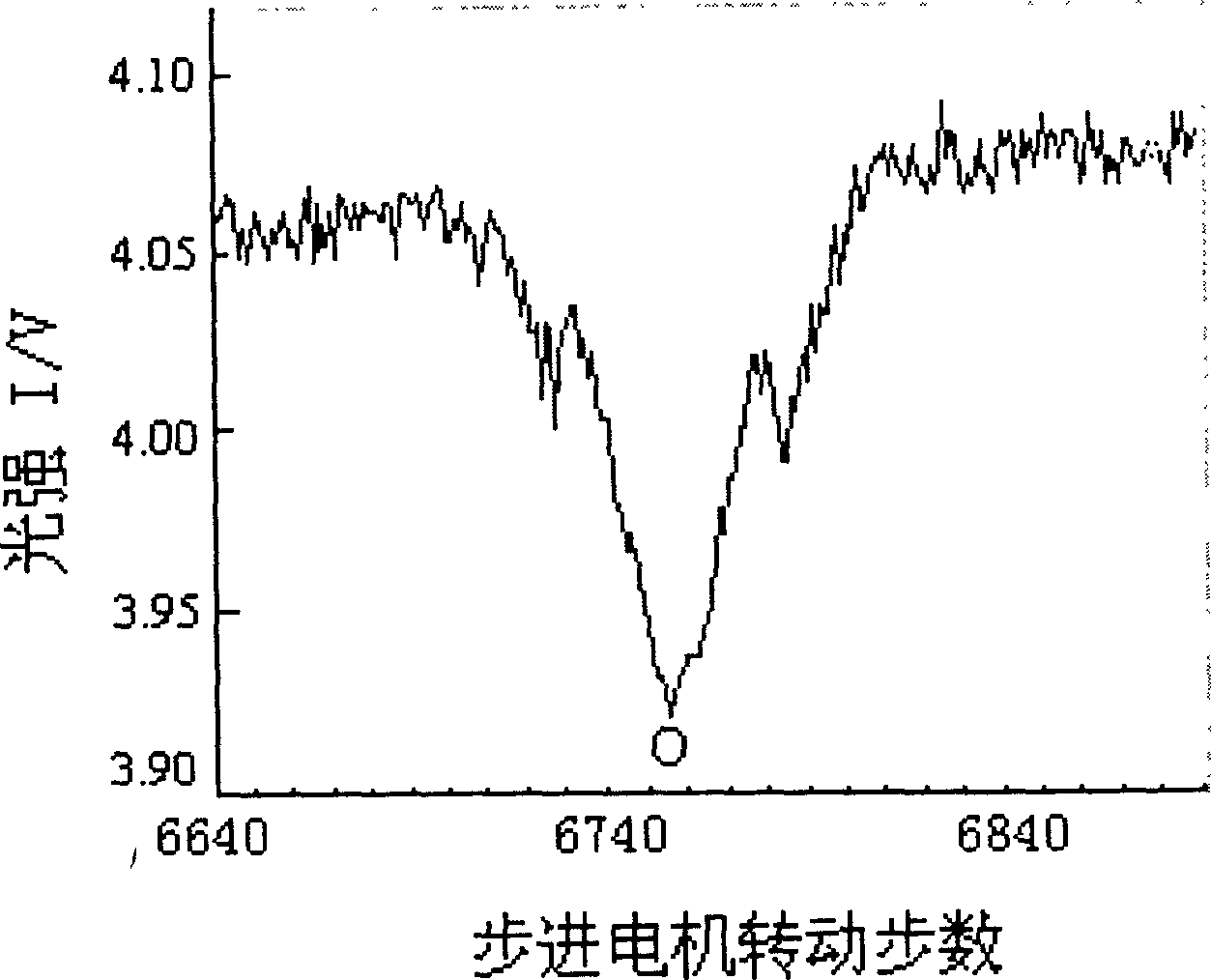

[0015] figure 1 The specific structure of the slab waveguide synchronous angle device using the prism coupling method of the present invention is shown, by figure 1 It can be seen that the device includes components such as a rotating platform 1, a laser 2, a polarizer 3, a diaphragm 4, a prism 5, a detector 6, an A / D converter 7, a computer 8, and a stepping motor 9. Place the slab waveguide 10 (the slab waveguide is composed of a substrate and a film attached to it), the laser light emitted by the laser 2 passes through the polarizer 3 and the diaphragm 4 and enters the prism 5, and is reflected by the prism 5 and then enters the detector 6. The detector 6 is connected with the A / D converter 7 and the computer 8 , and the stepping motor 9 which drives the platform 1 to rotate is connected with the computer 8 at the same time. Utilize aforementioned device to realize the concrete steps of the inventive method and be: the operator sends instruction by computer, allows stepper...

Embodiment 2

[0019] This embodiment is the same as embodiment 1 except the following features: for the same measurement point, keep the same test conditions as in embodiment 1, the prism rotates counterclockwise, and table 2 is the number of steps of the above-mentioned three adjacent guided modes measured displacement, measured three times.

[0020] Table 2

[0021]

[0022] Take the average value of the clockwise and counterclockwise step displacements of the same pattern, and multiply the average step displacement by the step angle value, which is the corresponding incident angle of this point. In this embodiment, through two-way measurement, the measurement error caused by the change of the output light intensity of the light source lagging behind the reflected light entering the light source is eliminated, so the result is more accurate. Table 3 is the average value of step number displacement and the refractive index and film thickness (step length angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com