Jacket type glass piston preparation process

A preparation process and jacketed technology, which is applied in the field of preparation of jacketed glass pistons, can solve the problems of affecting measurement accuracy, increasing operating costs, and difficulty in meeting the requirements of temperature control accuracy, so as to improve the constant temperature accuracy and eliminate stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

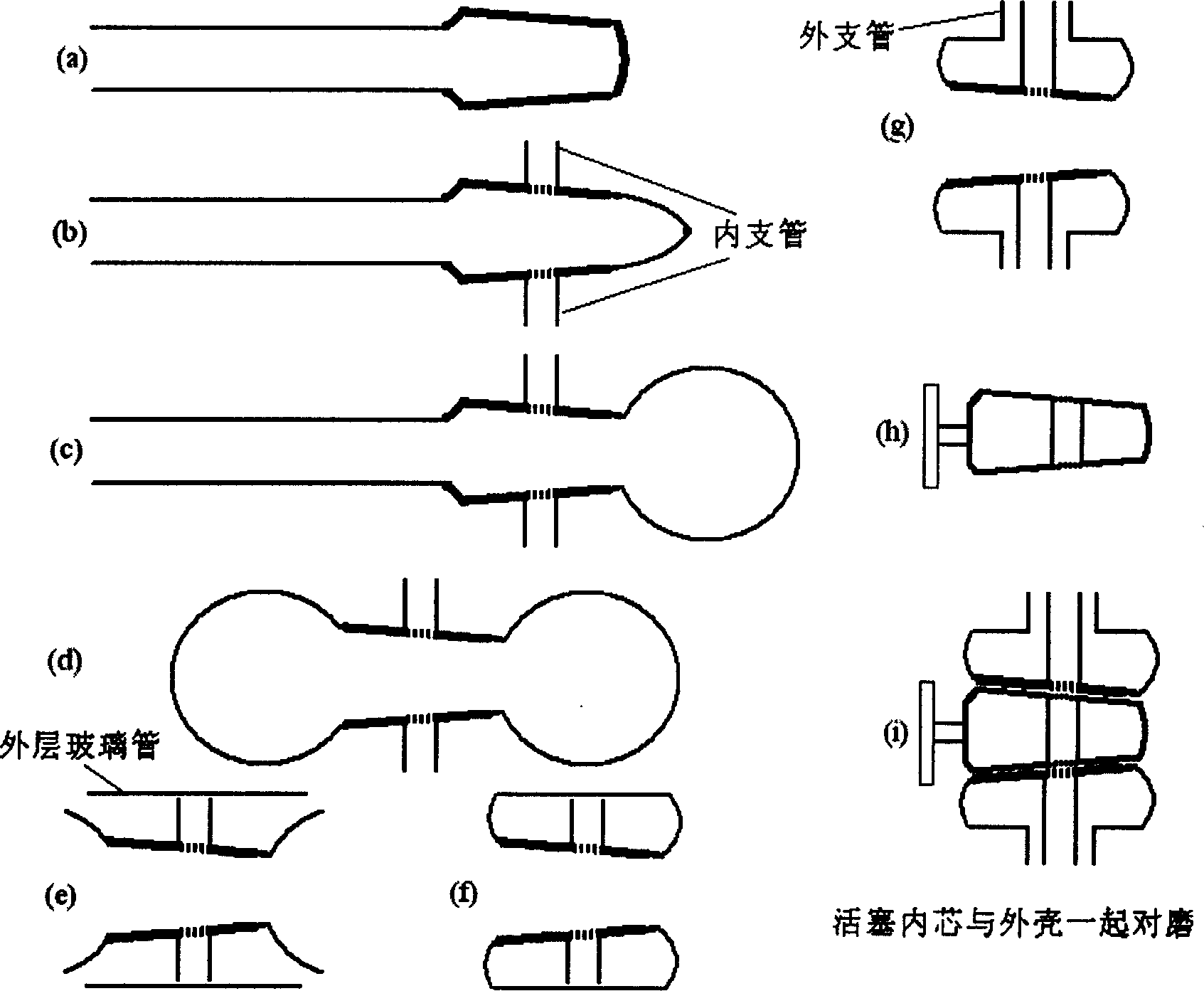

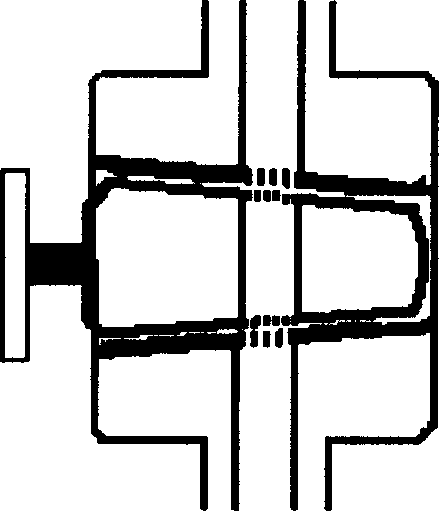

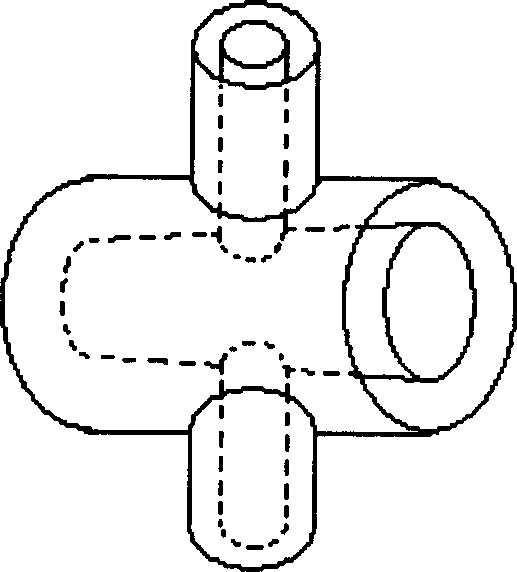

[0026] Such as figure 1 As shown, the steps of the preparation process are as follows:

[0027] First, blow the piston shell with a nipper as the inner layer of the jacket, as shown in (a);

[0028] Second, blow a small head and connect a glass tube to melt it, as shown in (b);

[0029] Third, open a port on both sides of the shell, and then vertically externally connect two glass tubes of equal length as the inner branch pipe. The distance between the two inner branch pipe ports should be slightly smaller than the inner diameter of the outer glass tube of the piston jacket. Use a small cork. Tighten the two pipes, as shown in (b);

[0030] Fourth, blow one end of the fused glass tube into a glass ball, as shown in (c);

[0031] Fifth, blow the big head into a glass ball, as shown in (d);

[0032] Sixth, cut off a part of the glass balls at both ends on the flame, and put a glass tube of moderate length as the outer layer of the jacket, as shown in (e);

[0033] Seventh, connect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com