Culture media composition suitable for cultivating high-density high-quality ordinary chlorella

A technology of common chlorella and culture medium, which is applied in the field of high-density and high-quality culture of common chlorella, and can solve problems such as inability to achieve high-density and high-quality culture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

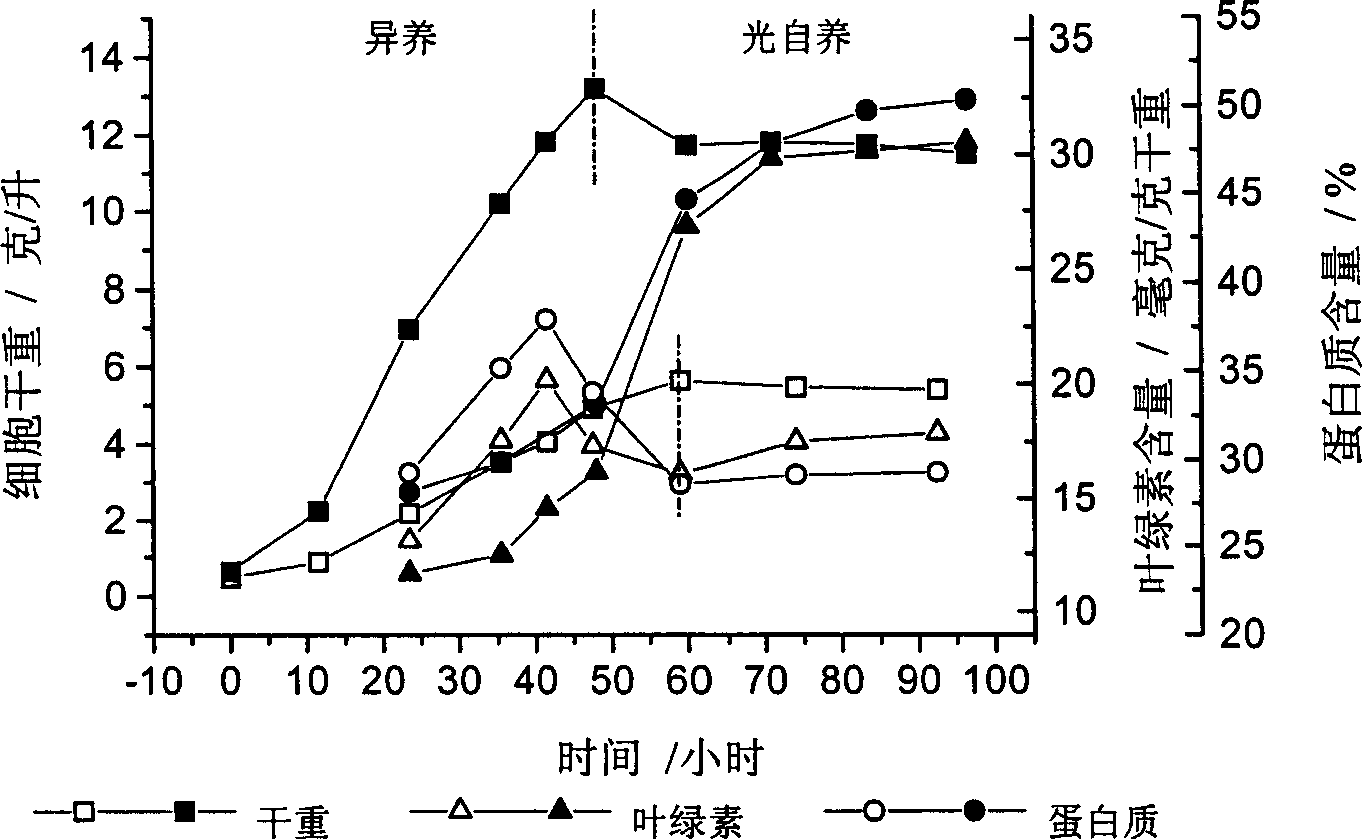

[0038]Add 100ml of the medium shown below to a 250ml shake flask, and the inoculation concentration is 0.62g / L. Heterotrophic culture (100mL liquid volume, 30°C temperature, 150r / min shaker speed) for 48 hours, the result is to measure the cell density () was 13.17g / L at the maximum, followed by photoautotrophic culture (external light intensity 8klx), at the end of the culture (96h) the contents of algae protein () and chlorophyll () reached the highest, 49.75% and 30.17mg / gDcw respectively (See figure 1 ).

[0039] KNO 3 : 9.25 Glucose: 30

[0040] KH 2 PO 4 : 0.7 Na 2 HPO 4 ·12H 2 O: 1.84

[0041] MgSO 4 ·7H 2 O: 0.7CaCl 2 : 0.142

[0042] FeSO 4 ·7H 2 O: 0.02

[0043] Trace element: 1ml; trace element formula (g / L): H 3 BO 3 11.42 ZnSO 4 ·7H 2 O 8.82

[0044] MnCl 2 ·H 2 O 1.42 (NH 4 ) 6 Mo 7 O 24 ·4H 2 O 0.8707

[0045] CuSO 4 ·5H 2 O 1.57 Co(NO 3 ) 2 ·6H 2 O 0.49

[004...

Embodiment 2

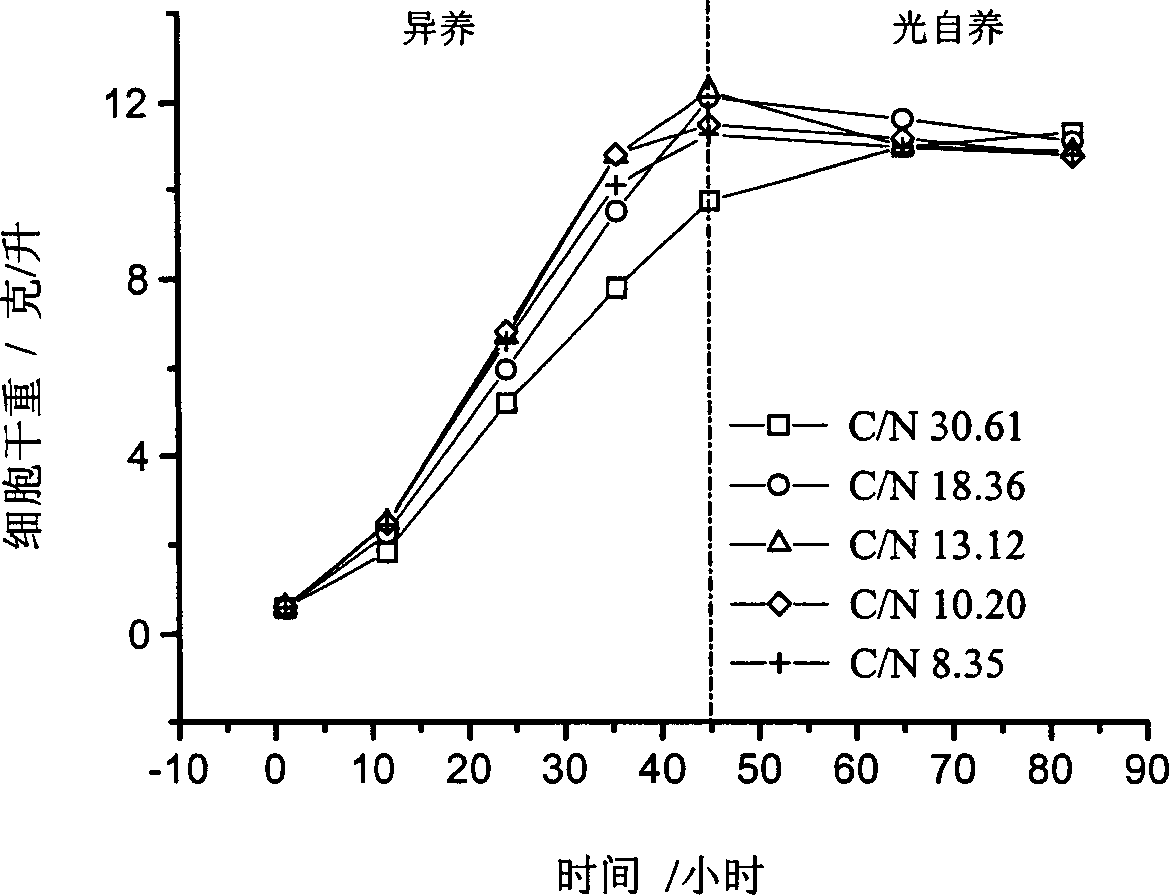

[0064] In a 250ml shake flask add 100ml of the medium shown below with KNO 3 The initial concentrations were 3, 5, 7, 9, and 11 g / L respectively, the inoculation concentration was 0.60 g / L, and the culture was carried out for 82 hours (wherein the heterotrophic culture was 45 hours, wherein the liquid filling volume was 100 mL, the temperature was 30 ° C, and the shaker speed was 150 r / min; photoautotrophic culture for 37 hours, external light intensity 8klx). The result measured KNO 3 At 7~9g / L (calculated as 10.20~13.12 by C / N ratio), the maximum cell density is about 12.0g / L (see image 3 ), the protein and chlorophyll content of the algae also reached the highest levels, around 50.0% and 32.0 mg / gDcw, respectively (see Figure 4 ).

[0065] KNO 3 : 3, 5, 7, 9, 11 Glucose: 30

[0066] KH 2 PO 4 : 0.7 Na 2 HPO 4 ·12H 2 O: 1.84

[0067] MgSO 4 ·7H 2 O: 0.7CaCl 2 : 0.142

[0068] FeSO 4 ·7H 2 O: 0.02

[0069] Trace elements: 1ml

[0070] Trace element formu...

Embodiment 3

[0075] The medium shown below was added to the 5L bioreactor / 1L open plate photobioreactor series system, the filling volume was 75%, the inoculation concentration was 0.60g / L, and the culture was carried out for 65 hours (among which the 5L bioreactor was cultured in 34 hours, 31 hours in a 1L open-plate photobioreactor). The results showed that the cell density ( ) reached a maximum of 15.36 g / L at 34 hours of culture, and the contents of algal body protein ( ○ ) and chlorophyll ( ) reached the highest at 65 hours of culture, which were 54.78% and 31.23 mg / gDcw respectively (see Figure 5 ).

[0076] KNO3: 9.25 Glucose: 30

[0077] KH 2 PO 4 : 0.7 Na 2 HPO 4 ·12H 2 O: 1.84

[0078] MgSO 4 ·7H 2 O: 0.7CaCl2 : 0.142

[0079] FeSO 4 ·7H 2 O: 0.02

[0080] Trace elements: 1ml

[0081] Trace element formula (g / L): H 3 BO 3 11.42 ZnSO 4 ·7H 2 O 8.82

[0082] MnCl 2 ·H 2 O 1.42 (NH 4 ) 6 Mo 7 o 24 4H 2 O 0.8707

[0083] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com