Collecting tube with detection hole

A technology of detection holes and test holes, which is applied in the field of spinning device components, can solve problems such as affecting spinning quality, low production efficiency, troublesome operation, etc., so as to avoid inconvenient operation, improve spinning quality and production efficiency, and simplify operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

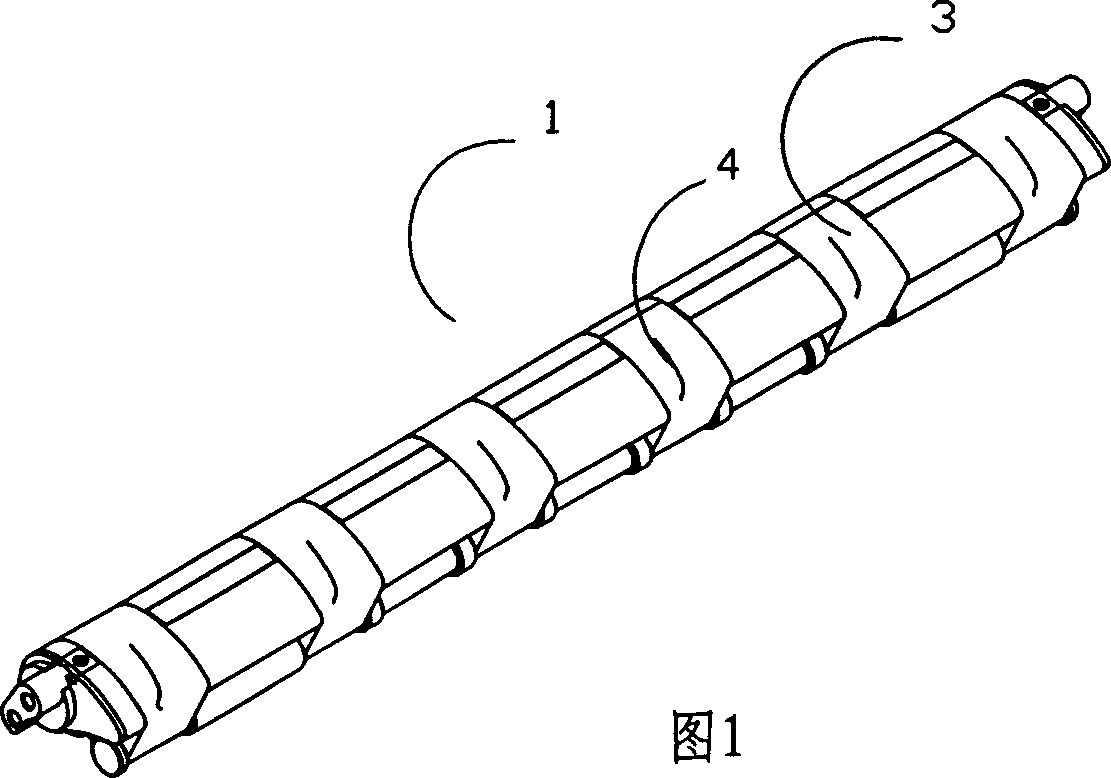

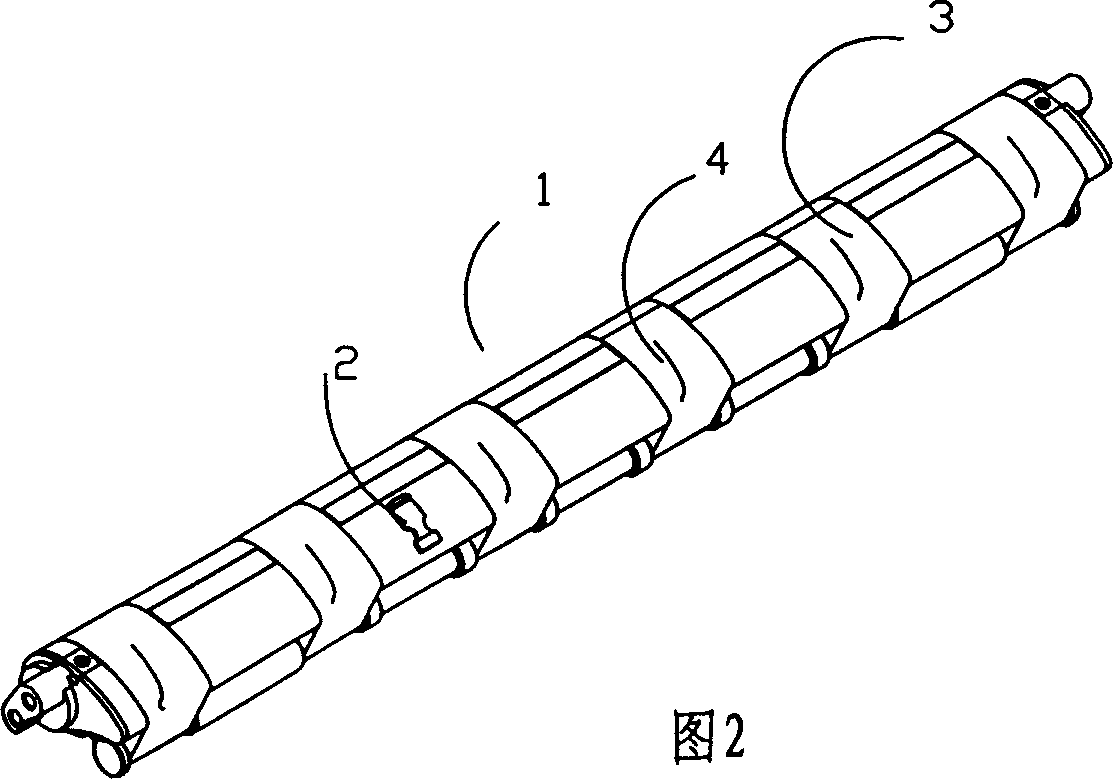

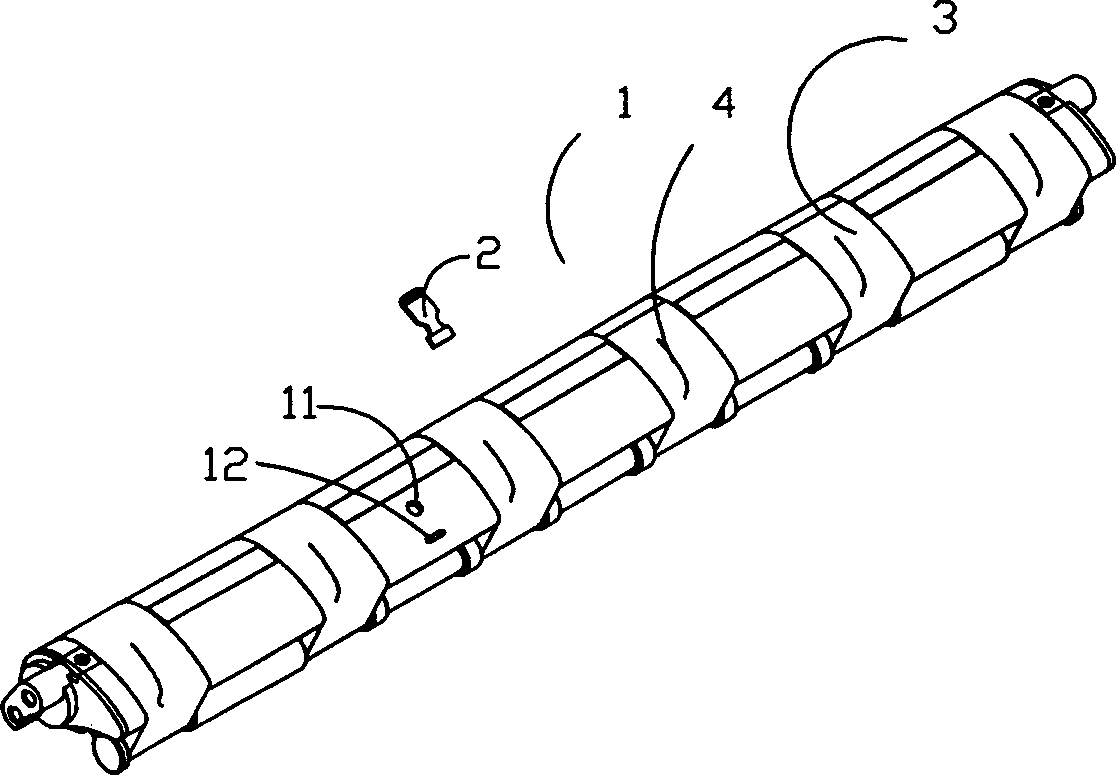

[0020] As shown in Figure 2, image 3 It is the collecting pipe 1 of the embodiment of the present invention. The collecting pipe 1 has a test hole 11 and a positioning hole 12 at the position away from the grid ring 3, and the corresponding sealing cover 2 has a sealing member 21 and a positioning member 22, and the positioning member 22 is inserted into the positioning In the hole 12, the sealing member 21 just covers the test hole 11.

[0021] The above-mentioned sealing member 21 is designed as a boss type, such as Figure 5 As shown, this facilitates better sealing of the test hole 11 of the collecting pipe 1 . It can also be designed into a flat shape, which can still be sealed under negative pressure.

[0022] Above-mentioned locator 22 can be designed into various shapes, is designed as arrow-shaped in the present embodiment, see F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com