High-power LED high-brightness lighting lamp

A high-power, lighting technology, applied in lighting devices, lighting and heating equipment, components of lighting devices, etc., can solve the problems of inability to meet the heat dissipation requirements of high-power LEDs, unsatisfactory heat dissipation, and poor use effects. Enhance the directional irradiation light intensity, improve the heat dissipation effect, and the effect of uniform light intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

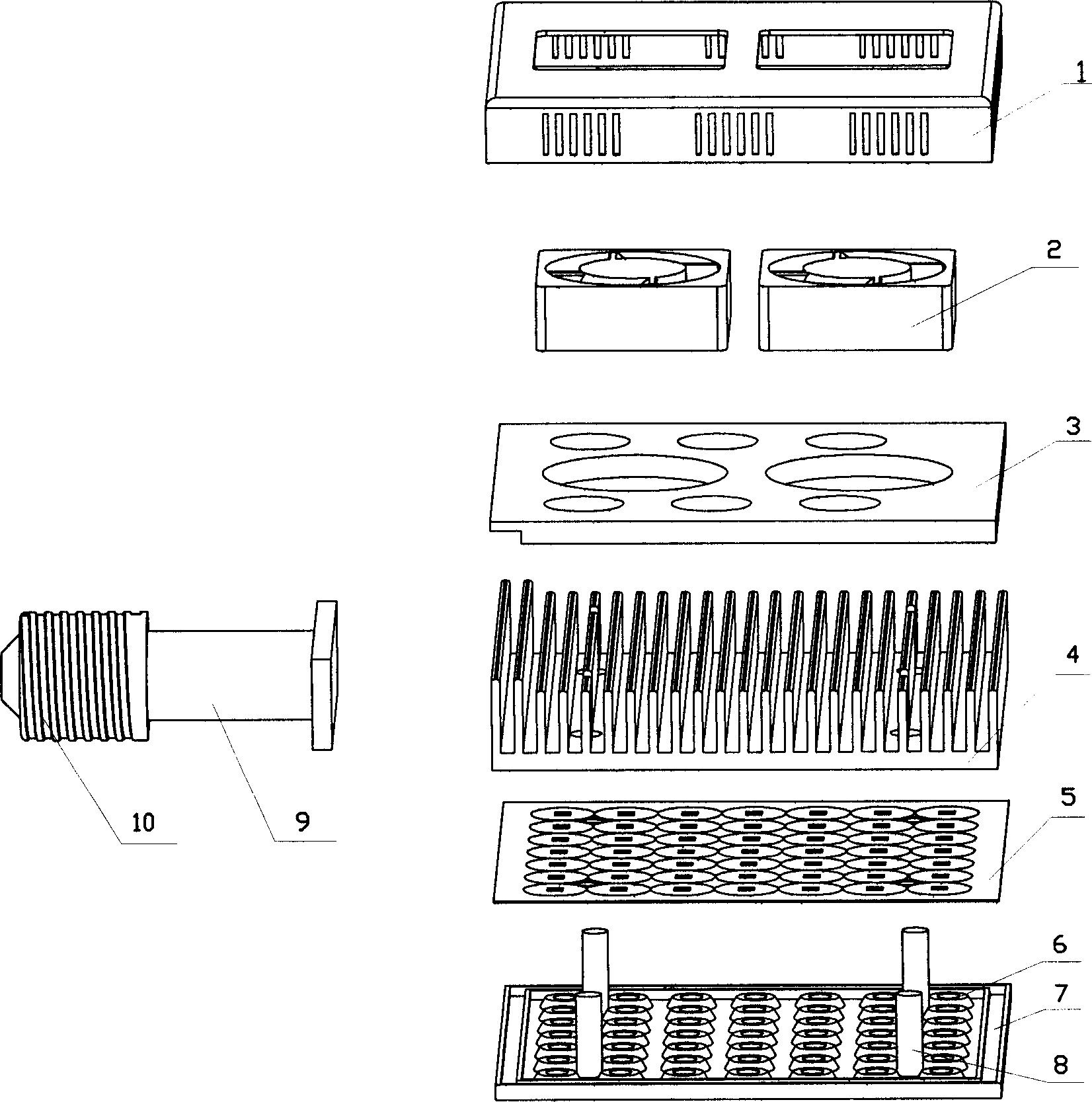

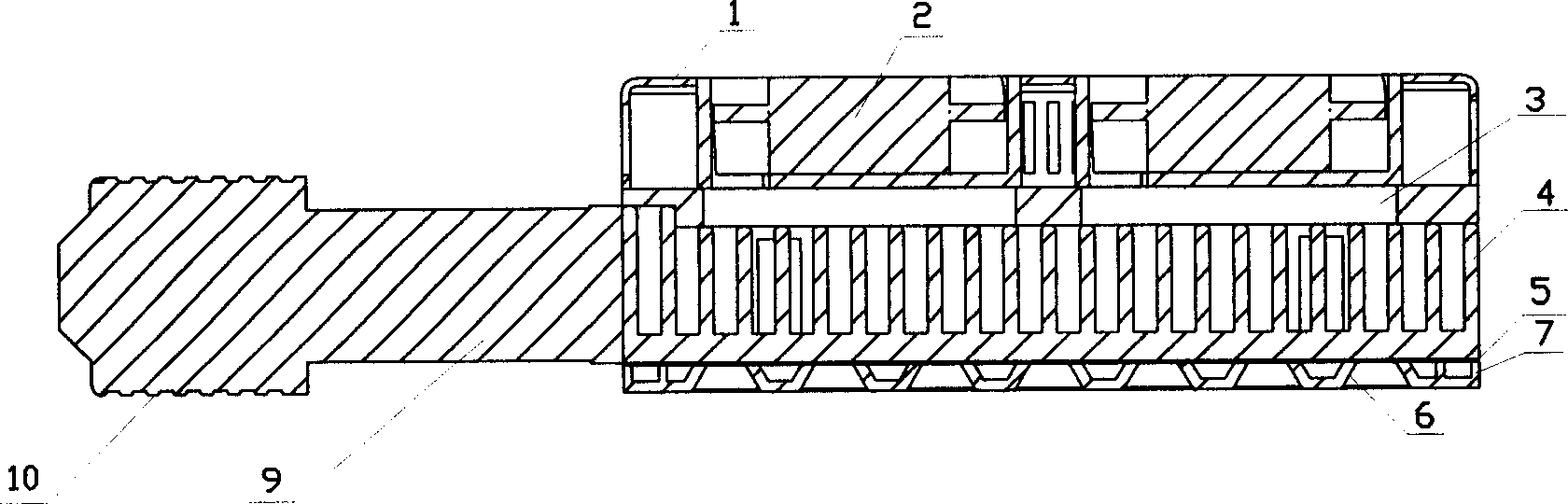

[0032] Embodiment 1: see Figure 1-Figure 7 , High-power LED high-brightness lighting street lamps, according to the direction of light projection, there are respectively fixed two cooling fans 2 Hollow cover 1 with heat dissipation windows, power supply mounting plate 3, aluminum heat dissipation plate with fins 4, LED light-emitting array 5 , the reflective bowl array 7 is superimposed and crimped with each other, and the screws are tightened to form, and the screw port of the handle 9 is fixed on the aluminum heat sink to connect the lamp holder 10.

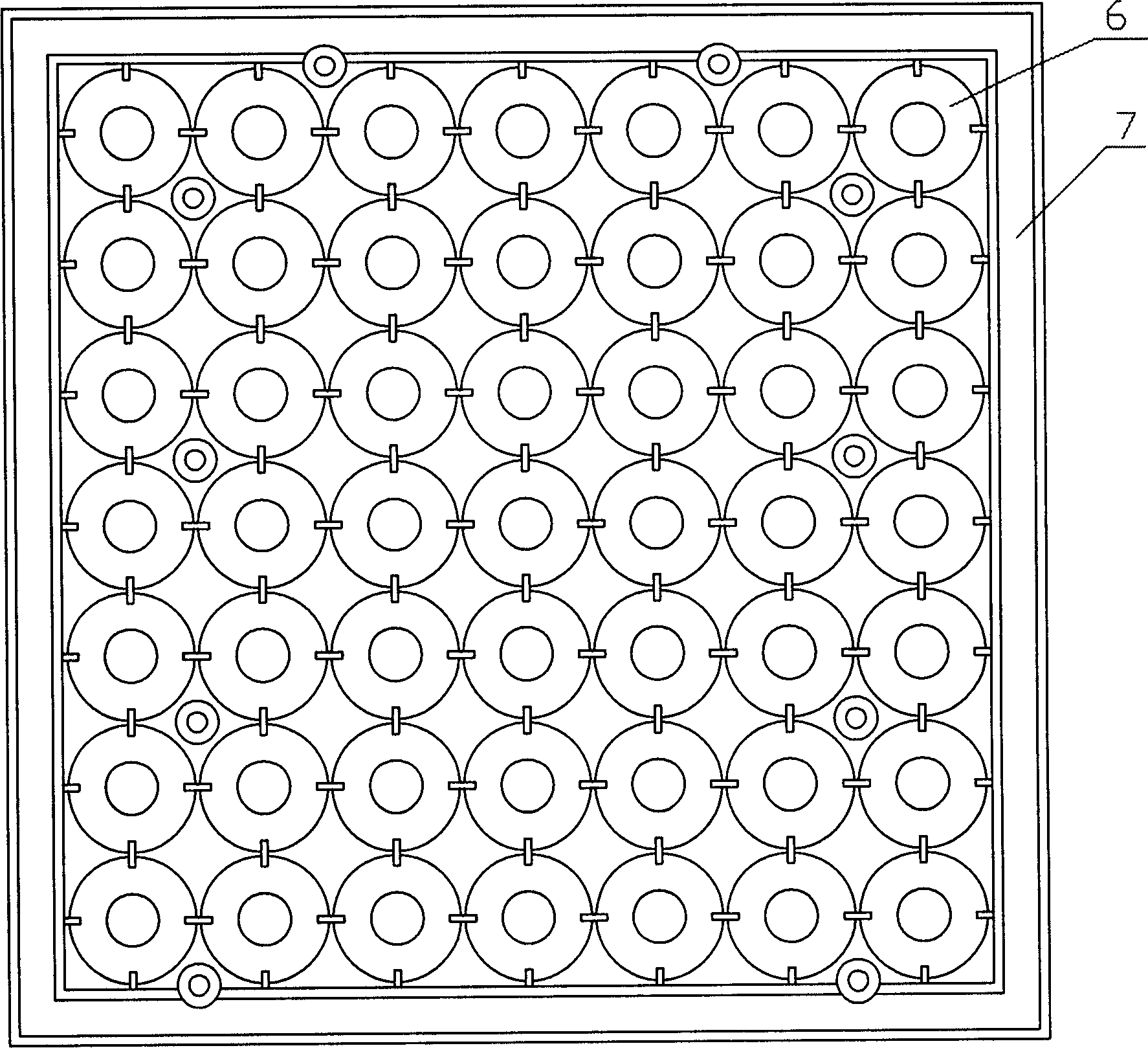

[0033] Wherein: the cooling fan 2 is a blowing fan; the reflective bowl array 7 ( image 3 , 4 ), which is integrally molded from plastic, and there are 7*7 reflective bowls 6 with 95-degree reflection angles regularly arranged at 20mm intervals in the center. The surface is coated with a silver-white reflective coating 11, and there are a number of protruding connecting columns 8 on the back, which are processed with Intern...

Embodiment 2

[0035] Example 2: see Figure 8, as in Example 1, the LED light-emitting array 5 has thermal conductive silicone grease 19 between the LED heat sink 13 on the back and the aluminum heat sink 4, so that heat conduction contact without air gaps is formed between the heat sinks of each light-emitting unit and the heat sink, which can further reduce the heat dissipation. Small thermal resistance, enhance heat dissipation effect.

[0036] In the street lamp test of the embodiment, the illuminance at 8 meters and 10 meters can reach 30lx and 20lx respectively, the color rendering index is 81, and the color temperature is 5570, which can completely replace the existing lighting street lamps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com