Carbon cluster synthesizing apparatus

A synthesis device and carbon cluster technology, applied in the field of fullerene preparation devices, can solve the problems of low yield, run-off, inconvenient collection, etc., and achieve the effects of low manufacturing cost, good retention ability, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

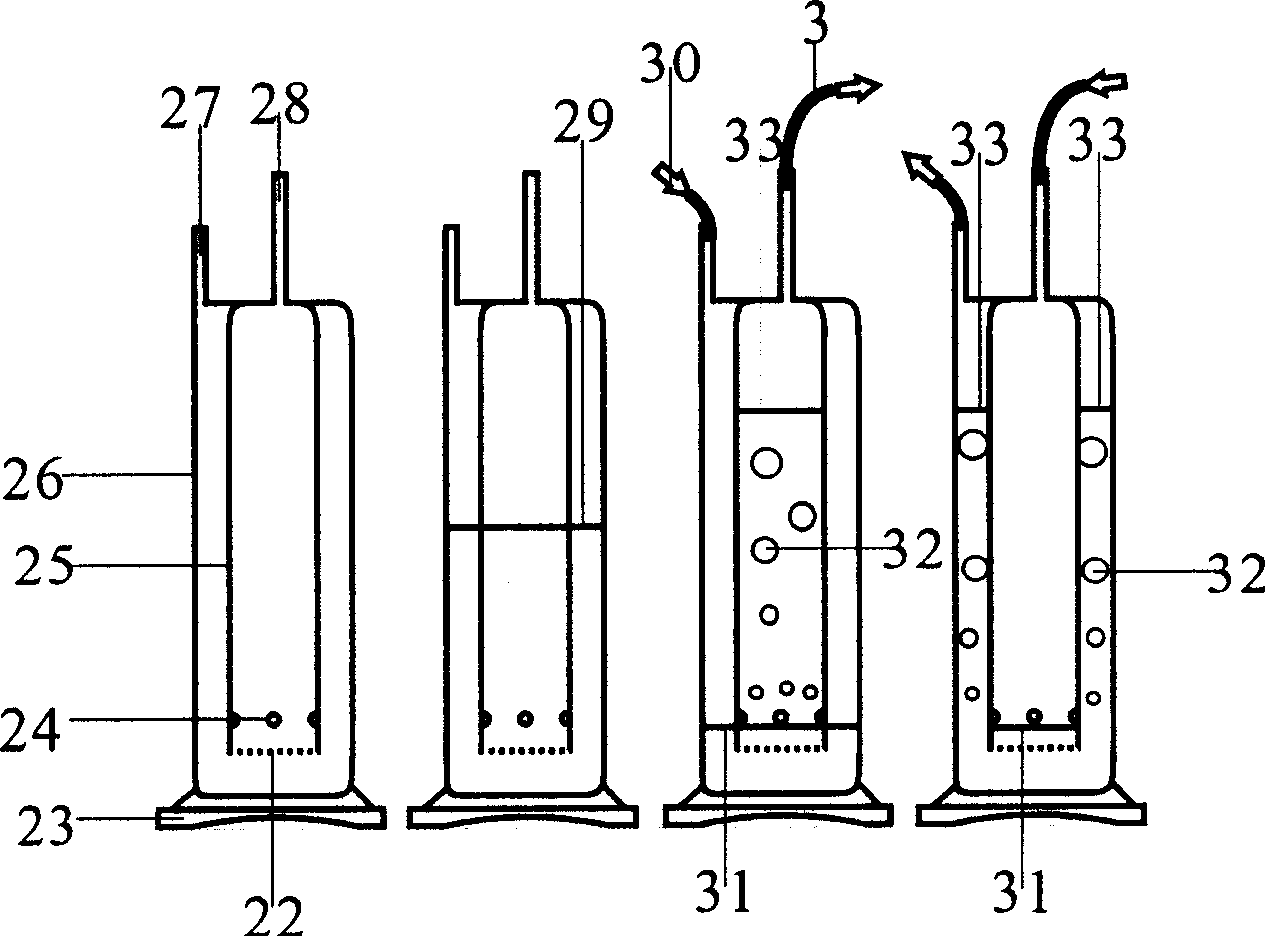

[0038] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

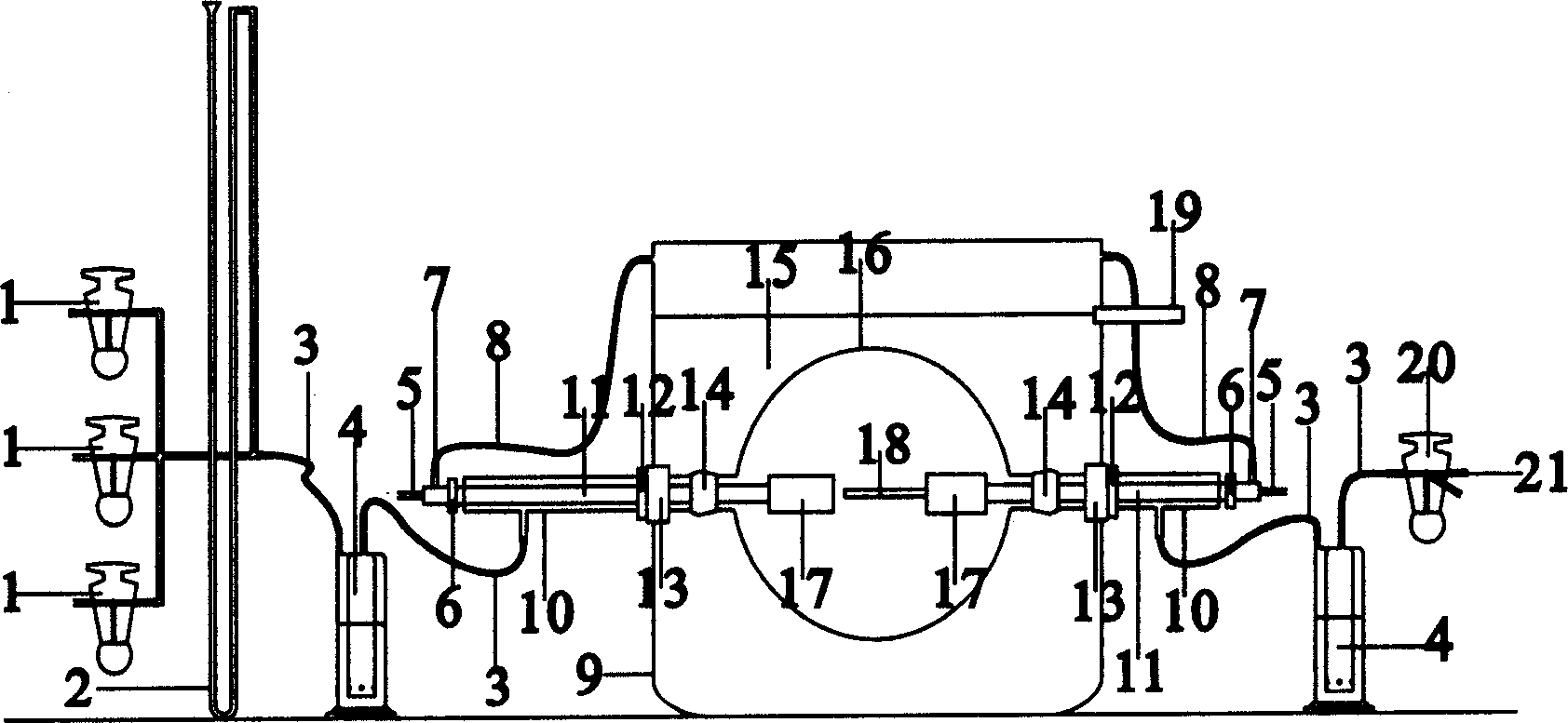

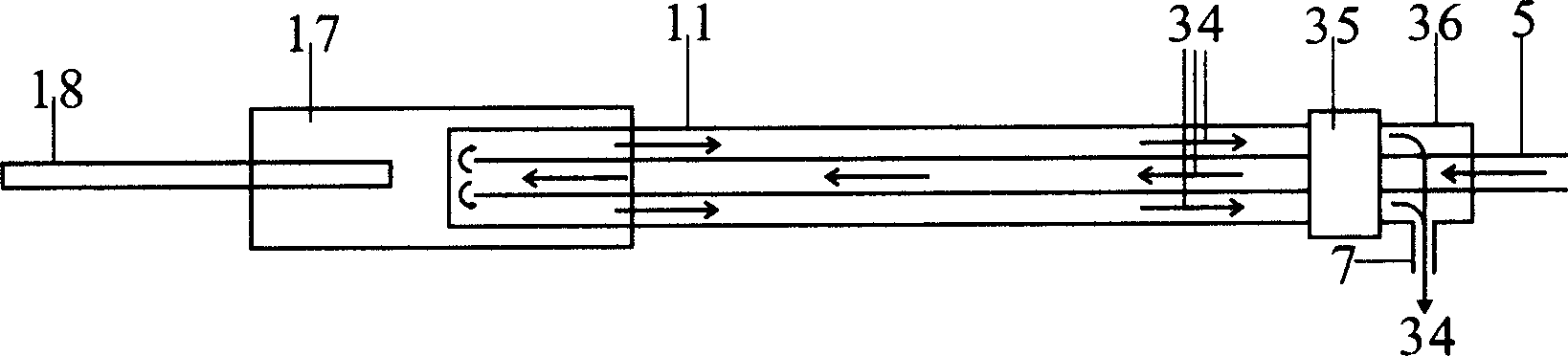

[0039] see figure 1 , The present invention is composed of air intake channel, exhaust channel, air pressure test and display device, liquid sealer, reaction chamber, vacuum pump, water cooling system and circuit parts.

[0040] (1) Intake channel and exhaust channel:

[0041] The inlet passage is a passage provided for introducing various buffer gases and different partial pressures of gases, through which a certain gas required for arc discharge can be introduced, and this gas with different partial pressures can be introduced. The exhaust channel is the channel for exhausting the residual gas after the reaction is completed and the channel for vacuumizing the system.

[0042] Buffer gases such as helium, argon, and nitrogen are introduced through the intake channel. The exhaust channel is used to discharge residual gas and vacuumize. The entire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com