High frequency heating apparatus having a steam generating function

A high-frequency heating and high-frequency heating device technology, which is applied to electric heating fuel, steam cooking utensils, lighting and heating equipment, etc., can solve problems such as difficult cleaning, decreased heating efficiency of heated objects, and uneven and rapid heating of the heating chamber. , to achieve the effect of maintaining cleanliness and improving operational performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

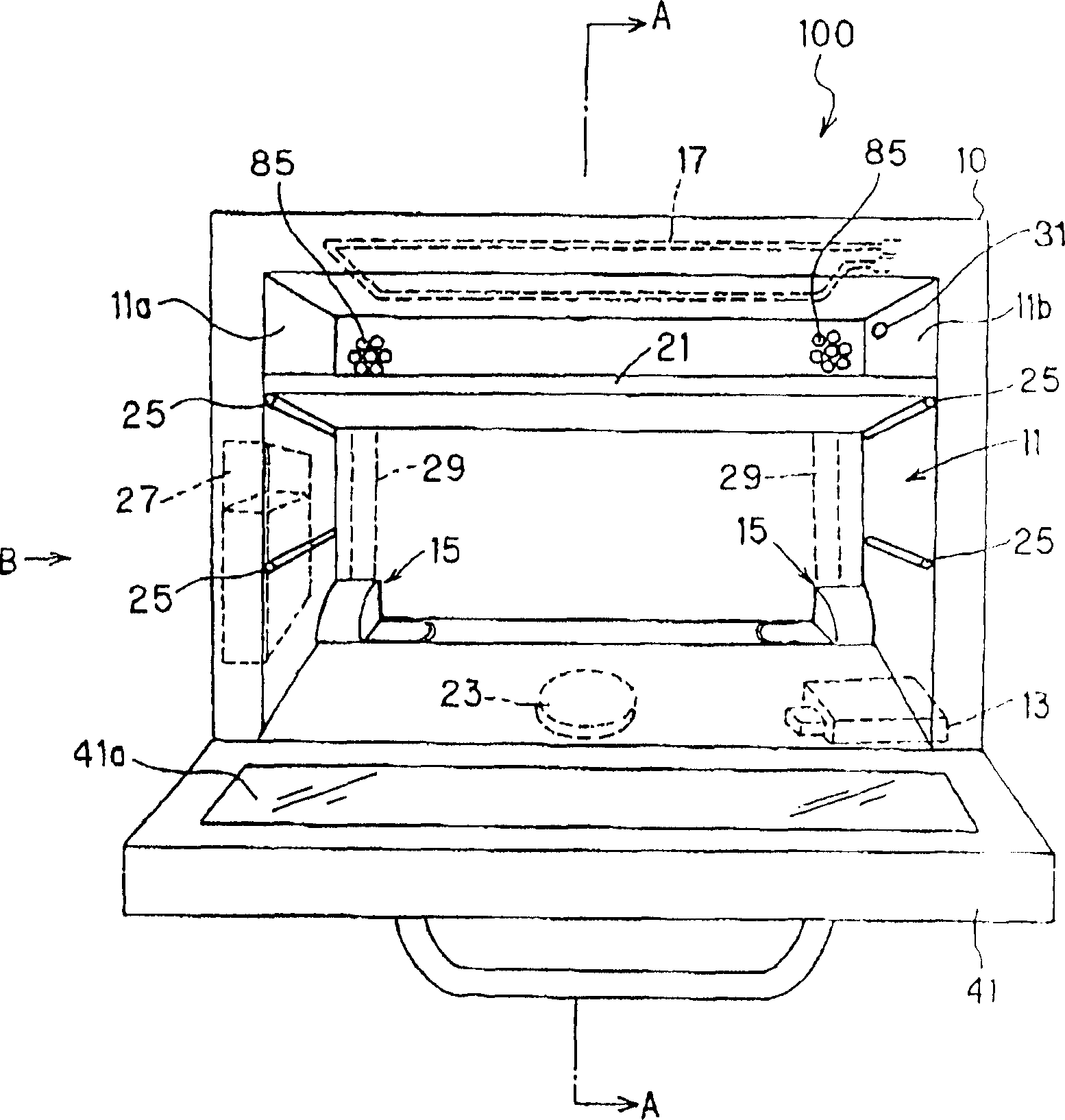

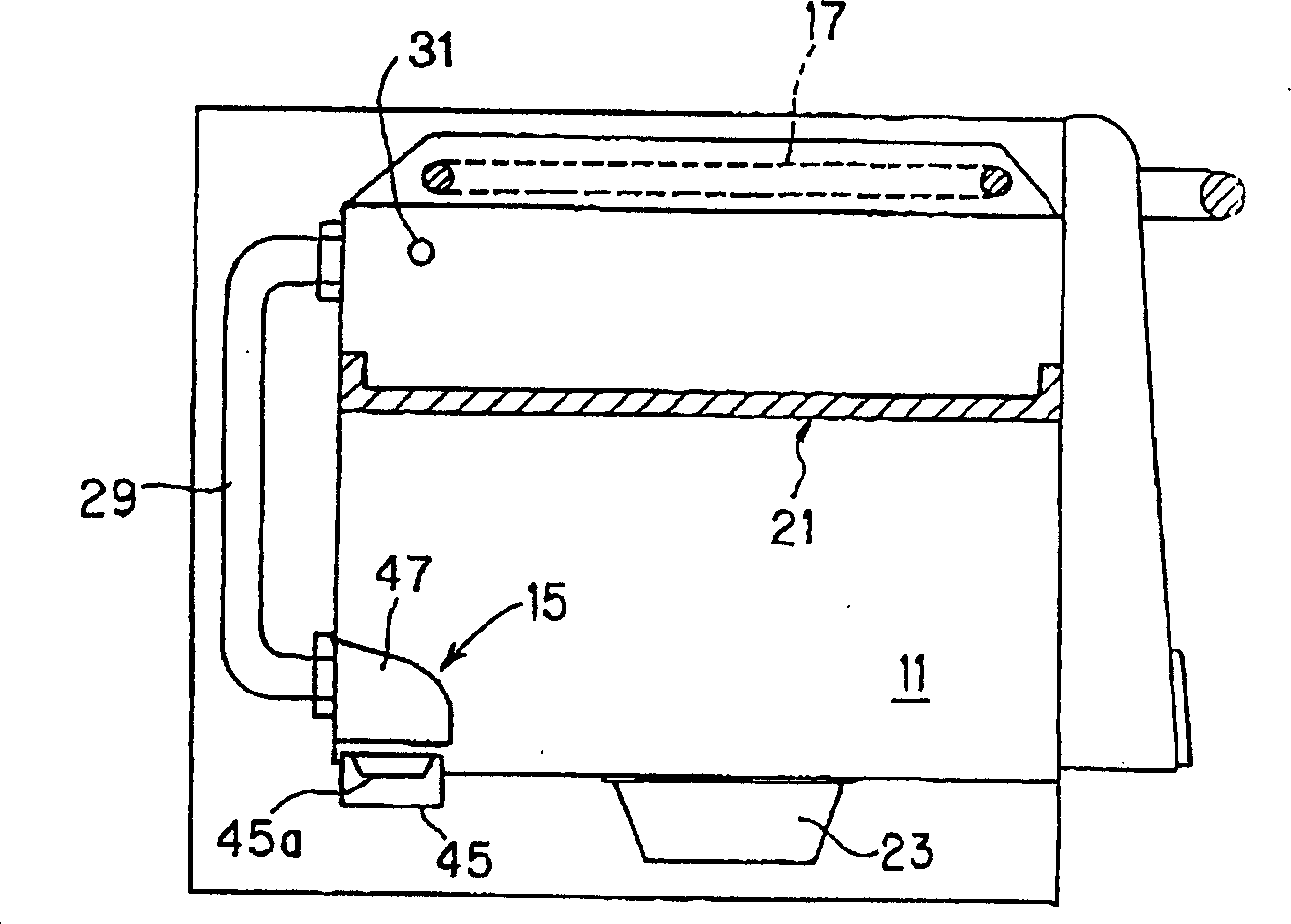

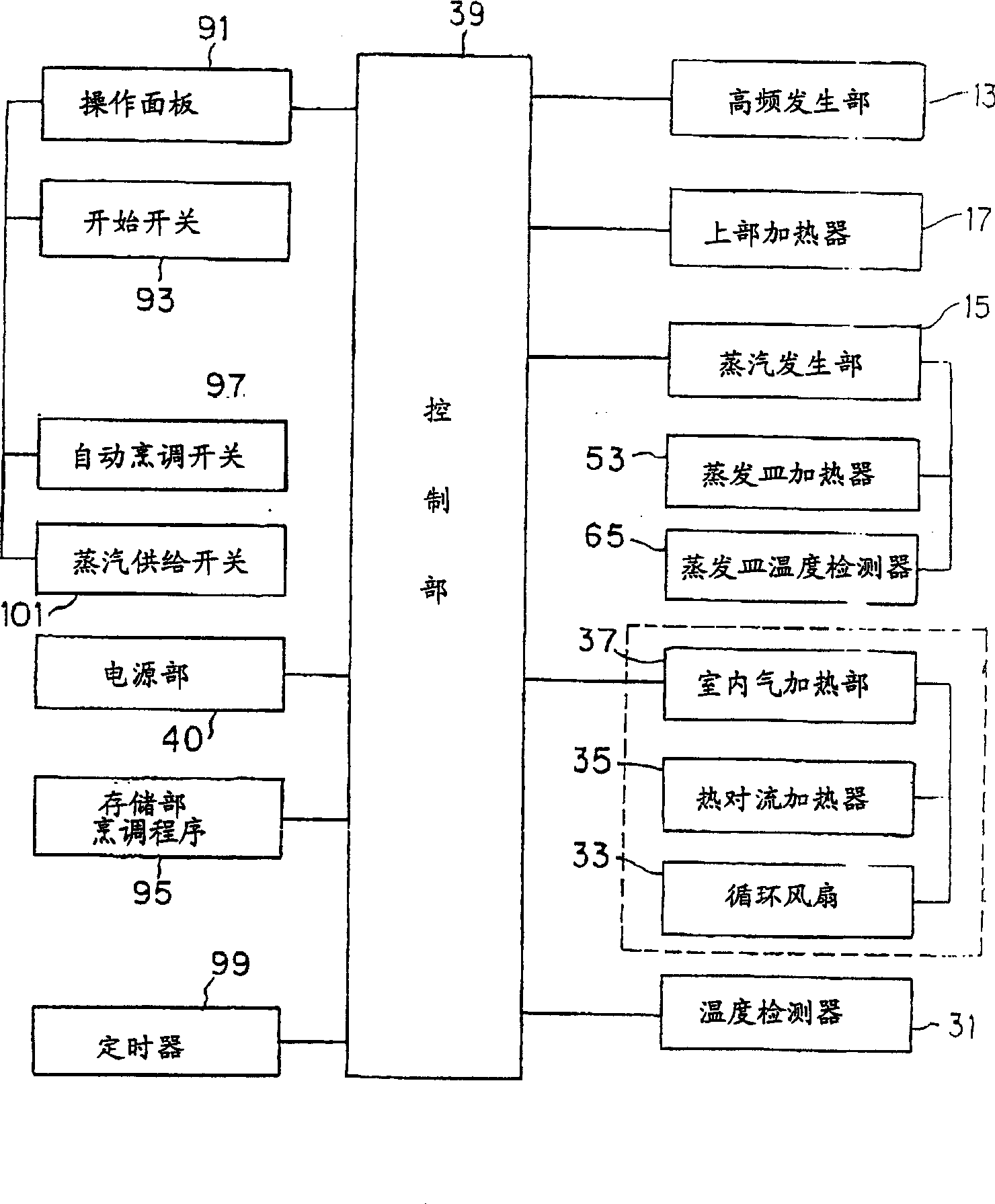

[0078] figure 1 It is a front view showing the door of the high-frequency heating cooker of the first embodiment of the present invention in an open state. figure 2 yes figure 1 A schematic view of the A-A section in, image 3 It is the control block diagram of the high-frequency heating cooker.

[0079] This high-frequency heating cooker 100 is a heating cooker for heating an object to be heated by supplying at least one of high frequency (high frequency) and steam to a heating chamber 11 in which an object to be heated is placed. Such as figure 1 As shown, it is characterized in that the space in the heating chamber 11 is divided into an upper space and a lower space by a tray 21 as a partition. This cooker 100 also has: a high-frequency generating part 13 composed of a magnetron generating high-frequency, a steam generating part 15 for generating steam in the heating chamber 11, and an upper heating device as a preheating device arranged above the heating chamber 11. ...

no. 2 example

[0143] Figure 19 with 20 It is a schematic structural sectional view of the high-frequency heating cooking device according to the second embodiment of the present invention.

[0144] Such as Figure 19 with Figure 20 As shown, the high-frequency heating cooking device includes: a heating chamber 111 for placing the object to be heated, and an upper heater 117, which is used as a heating device for heating the heater arranged on the upper part of the heating chamber, and is arranged on the deep bottom surface of the heating chamber. In the high-frequency generating part 113 that generates high-frequency and performs high-frequency heating, the steam generating part 115 that is arranged along the bottom surface of the heating chamber, that is, the back wall surface, is provided with a high-frequency heating element 177 on the inner surface as a placed heated object. Partition 117 of the pallet. The high frequency emitted from the high frequency generator 113 is transmitte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com