V-arc-shaped shallow slot structure and its machining method for composite floor

A compound flooring and arc-shaped technology, which is applied to wood processing equipment, manufacturing tools, building structures, etc., can solve the problems of weak solid wood feeling, easy to produce height difference, and exposed groove edge substrates, so as to achieve the goal of not easily hiding dirt and The effect of water accumulation, eliminating edge collapse and swelling, and improving the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

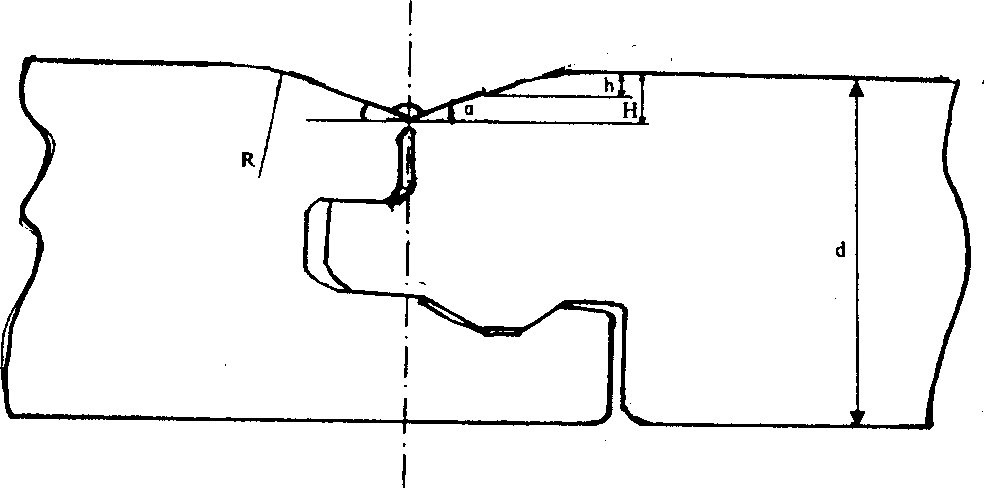

[0008] The technical solution of the present invention is: product structure: a circular arc shape with a corresponding radius R=6-15mm and an arc depth h=0.3-1.2mm is formed around the board surface, and the arc-shaped tangent slope transitions to the board edge, and the tangent slope and the board The bottom parallel lines form a V-shaped shallow groove with an angle of ∠α=11°~37°, the groove depth H=0.8~1.5mm, and the wear-resistant layer and decorative paper layer cover the entire surface of the floor including the board groove.

[0009] Production process: 2.1 Pass the broken blank through the floor forming machine, or pass the whole large slab through the router, and mill it around the surface of the floor slab with a corresponding radius R = 6 ~ 15mm, arc depth h = 0.3 ~ 1.2 The circular arc shape of mm, transition to the edge of the board with the arc-shaped tangent slope, the tangent slope and the parallel line of the bottom of the board form a V-shaped shallow groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com