Installation testing method of small hard-disk voice coil motor upper cover

A voice coil motor and hard disk technology, which is applied in the direction of instruments, record carrier structural parts, electrical digital data processing, etc., can solve the problems of not working properly, high position of voice coil motor, height increase, etc., to improve productivity and yield , Ensure the installation accuracy, accelerate the effect of curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

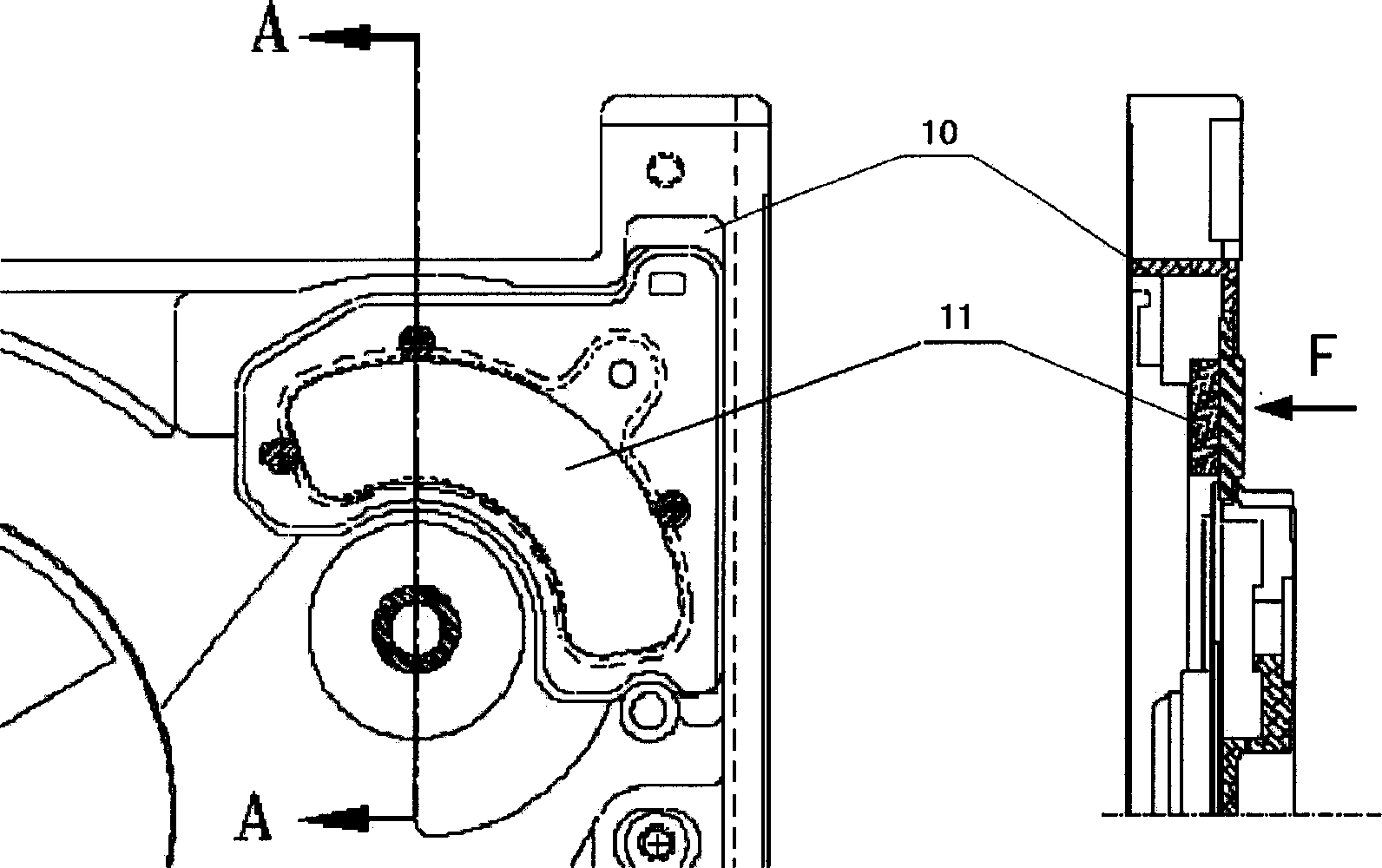

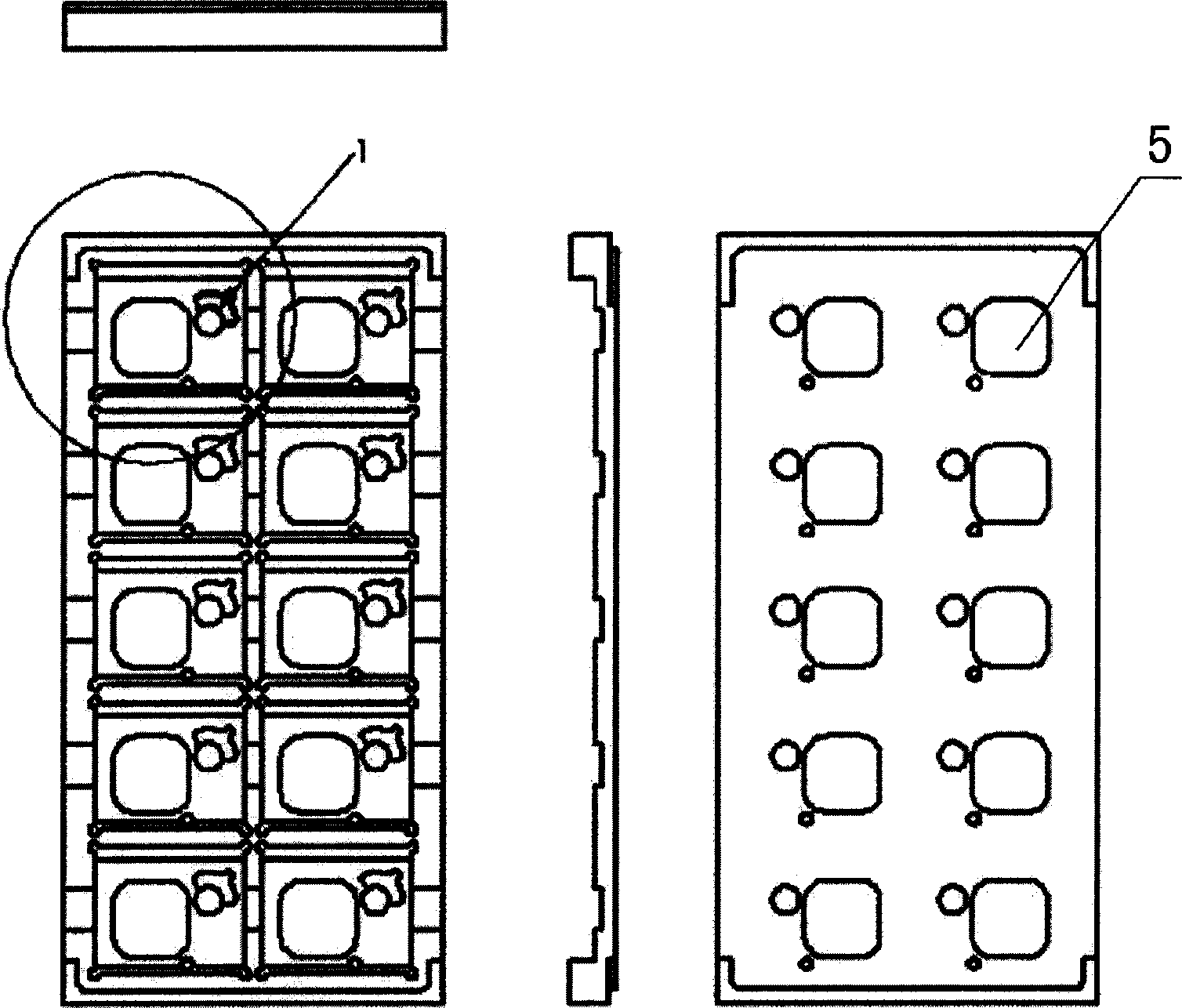

[0019] The various steps of the method for installing the lower cover of the small hard disk voice coil motor according to the present invention will be described in detail below with reference to the accompanying drawings.

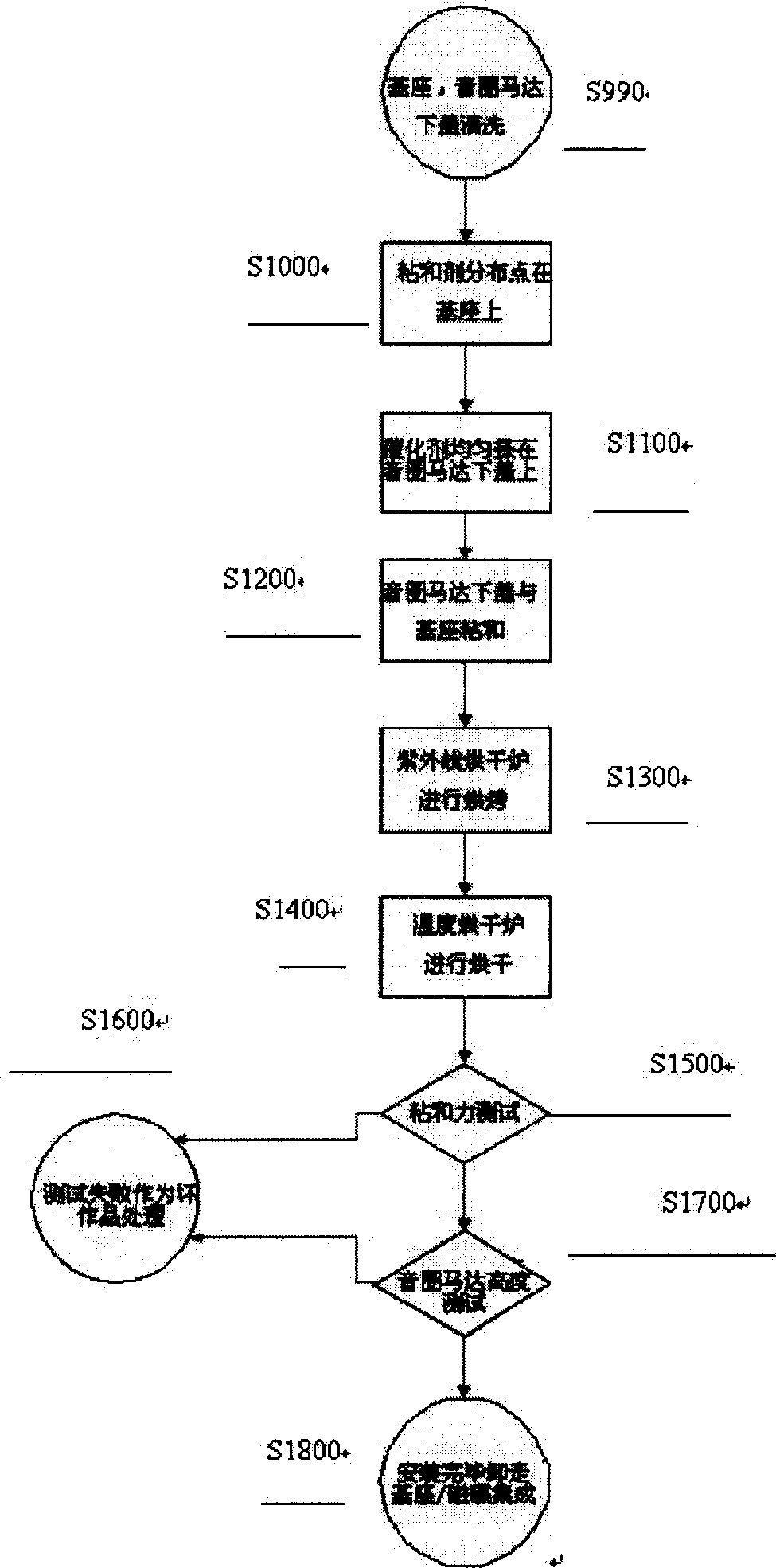

[0020] see figure 1 , which is a flowchart of the installation method according to the present invention.

[0021] Firstly, in step S990, the cleaning operation is performed on the lower cover and the base of the voice coil motor. Because the mechanical part of the hard disk has high dustproof requirements, the mechanical parts of the hard disk must be cleaned in the decontamination room before assembly. There is no particular limitation on the cleaning method, for example, this process can be realized by a cleaning method known in the art.

[0022] Then, in step S1000, an adhesive (for example, an adhesive commonly used in this field, such as glue, but not limited thereto, may also be an adhesive for special purposes) is uniformly placed on the Where ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com