Thermal evaporation physical vapor deposition system and use method thereof

A technology of physical vapor deposition and thermal evaporation, which is applied in vacuum evaporation plating, metal material coating process, coating, etc., can solve the problems of not having multi-dimensional quality online detection function, and achieve the elimination of off-line monitoring of film quality and saving Cost, the effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

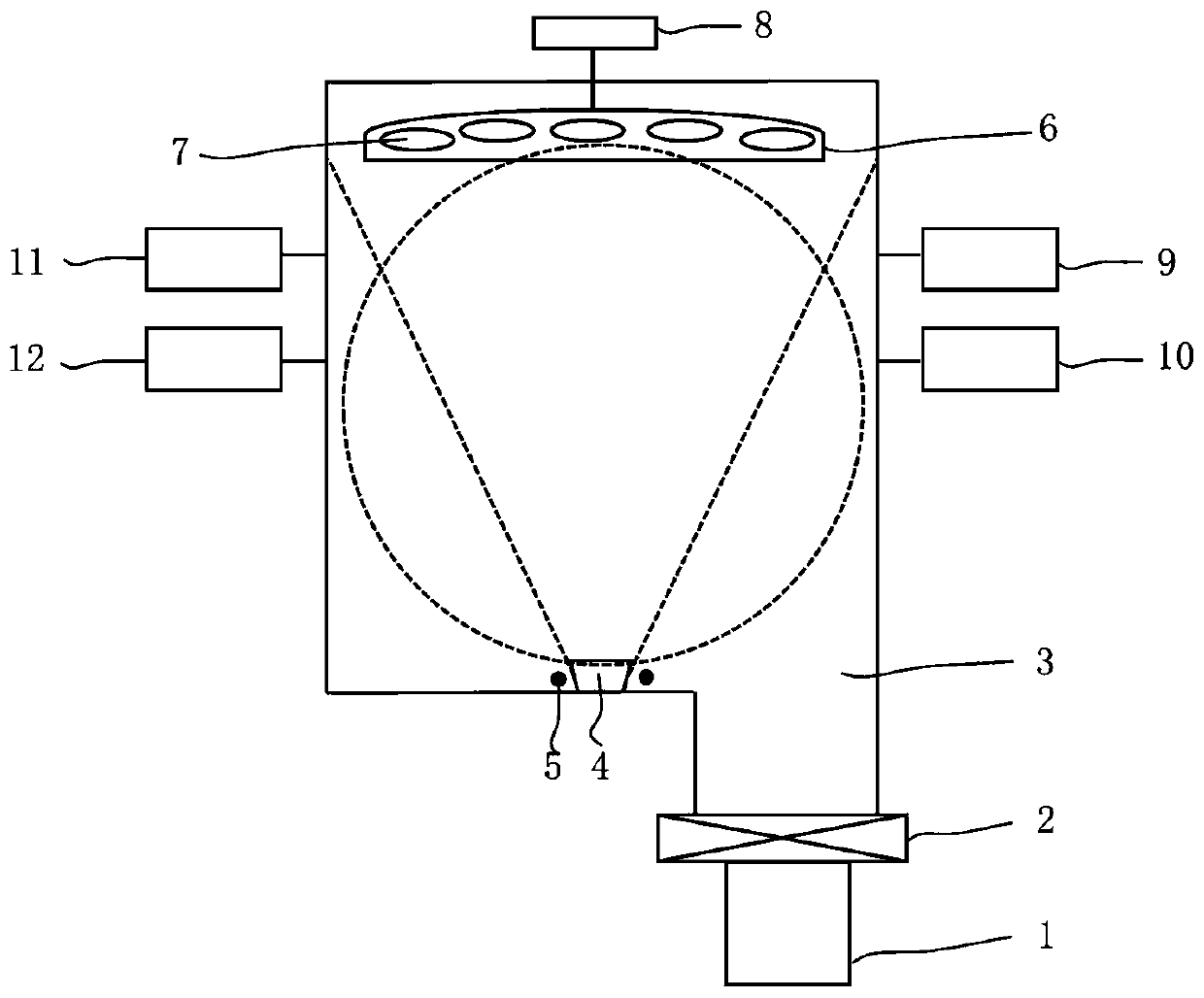

[0038] This embodiment provides a thermal evaporation physical vapor deposition system, such as figure 1 As shown, it mainly includes vacuum components and online monitoring components.

[0039] Wherein, the vacuum assembly includes a vacuum coating chamber 3 , a vacuum pump 1 , a vacuum valve 2 , a heater 5 , a substrate supporting table 6 , and a rotation driving motor 8 .

[0040] The vacuum valve 2 is installed between the vacuum pump 1 and the vacuum coating chamber 3 . The heater 5 is used to heat the crucible 4 . The substrate support table 6 is located in the vacuum coating chamber 3 and is connected to the rotation drive motor 8 , and the substrate support table 6 is used for placing a substrate 7 .

[0041] A crucible 4 is arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com