Engine

A technology for engines and rotating parts, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as strength reduction, increase in engine height, and difficulty in forming openings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] An embodiment of the present invention is described below.

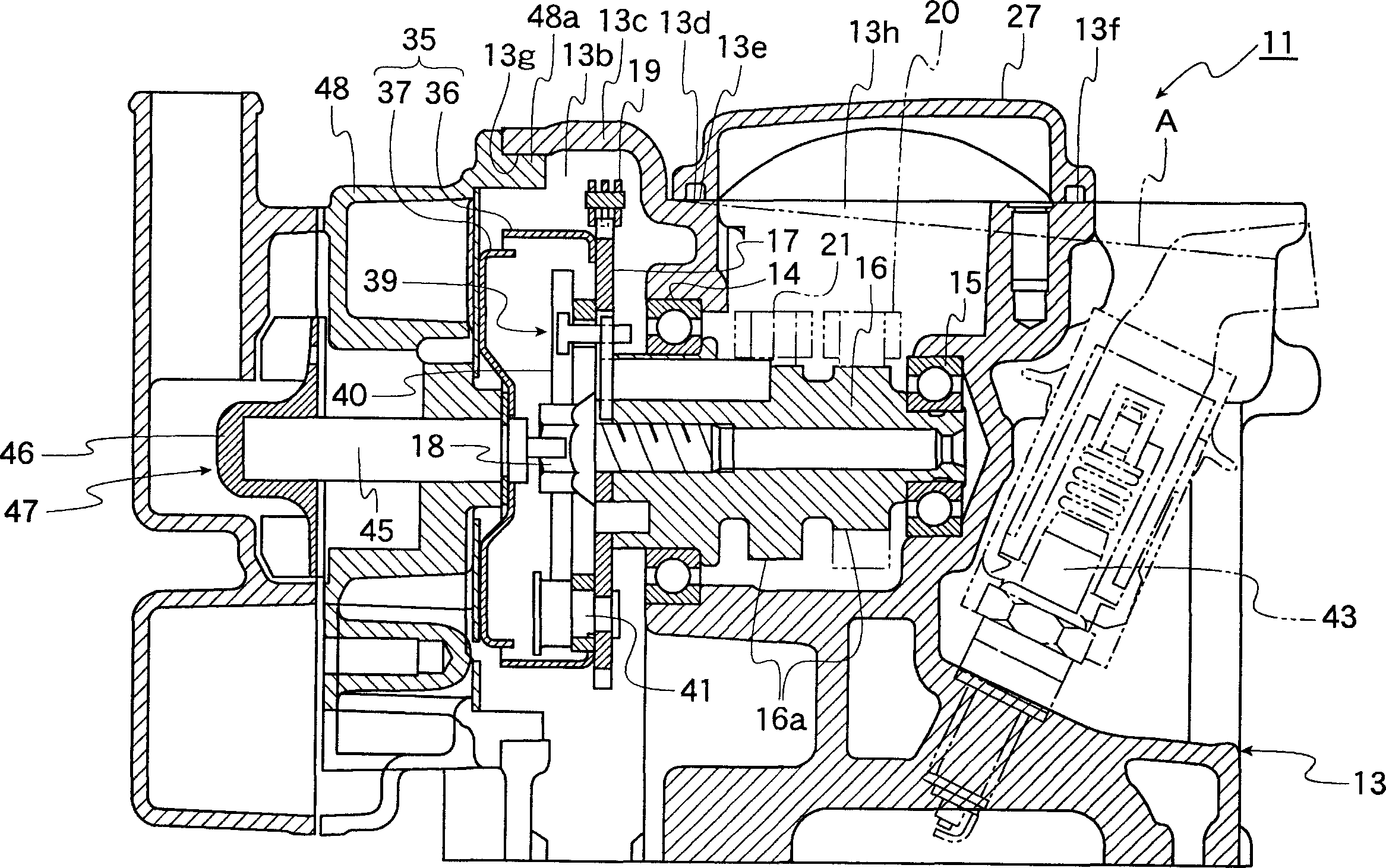

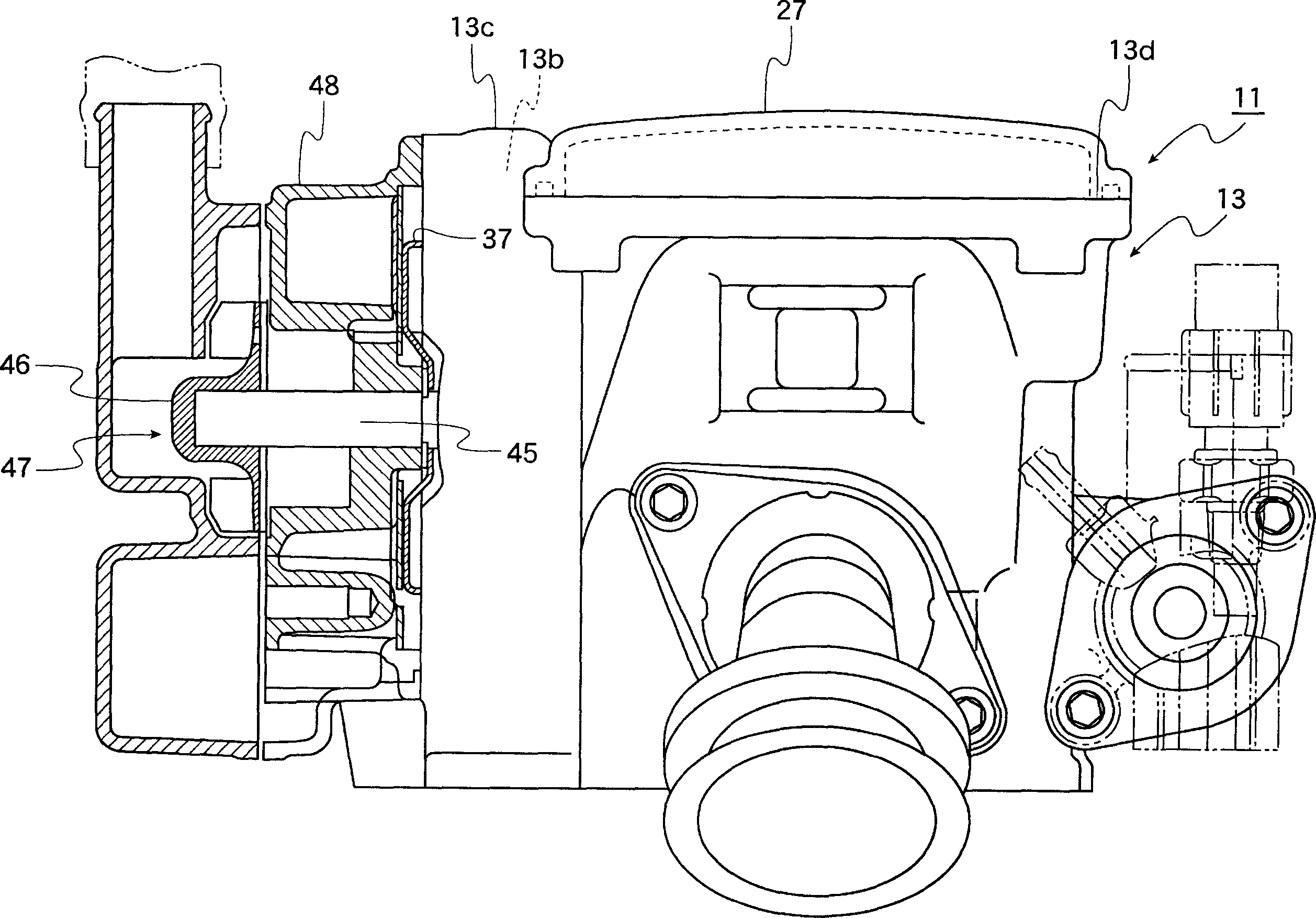

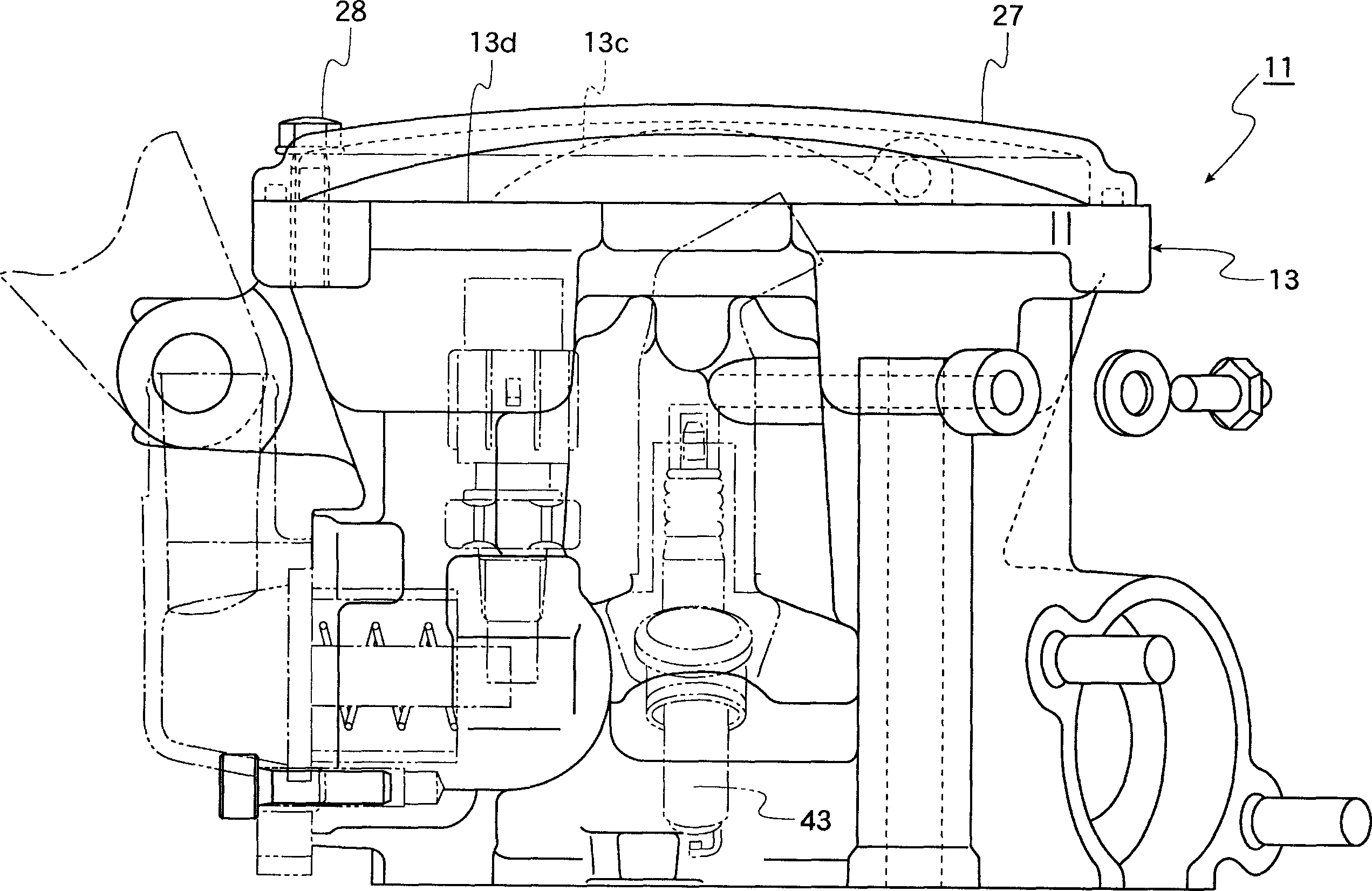

[0024] Figure 1-7 This embodiment of the invention is shown.

[0025] First, explain its structure, figure 1 Reference numeral 11 in denotes a single-cylinder four-stroke four-valve engine provided on a motorcycle, and the engine 11 includes a cylinder head 13 fixed to a cylinder block (not shown).

[0026] Such as figure 1 As shown, a camshaft 16 is rotatably provided on a cylinder head 13 through bearings 14 and 15 with different diameters, and a sprocket 17 as a "rotating part" is mounted on one end of the camshaft 16 through a bolt 18 . A cam chain 19 as a “wound (flexible) belt” is wound on the sprocket 17 so that the driving force from the crankshaft is transmitted to the sprocket 17 and the camshaft 16 through the cam chain 19 .

[0027] The camshaft 16 is formed with intake and exhaust cam portions 16a, such as Figure 5 As shown, one end 20 a , 21 a of the intake rocker arm 20 and the exhaust ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com