Method for preparing high density bulking ammonium nitrate explosive

A technology of expanded ammonium nitrate explosives and expanded ammonium nitrate, which is applied in the direction of explosives, etc., can solve the problems of reduced working ability, impact on rock blasting effect, and low energy density, and achieve the effects of increasing volume power, convenient operation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

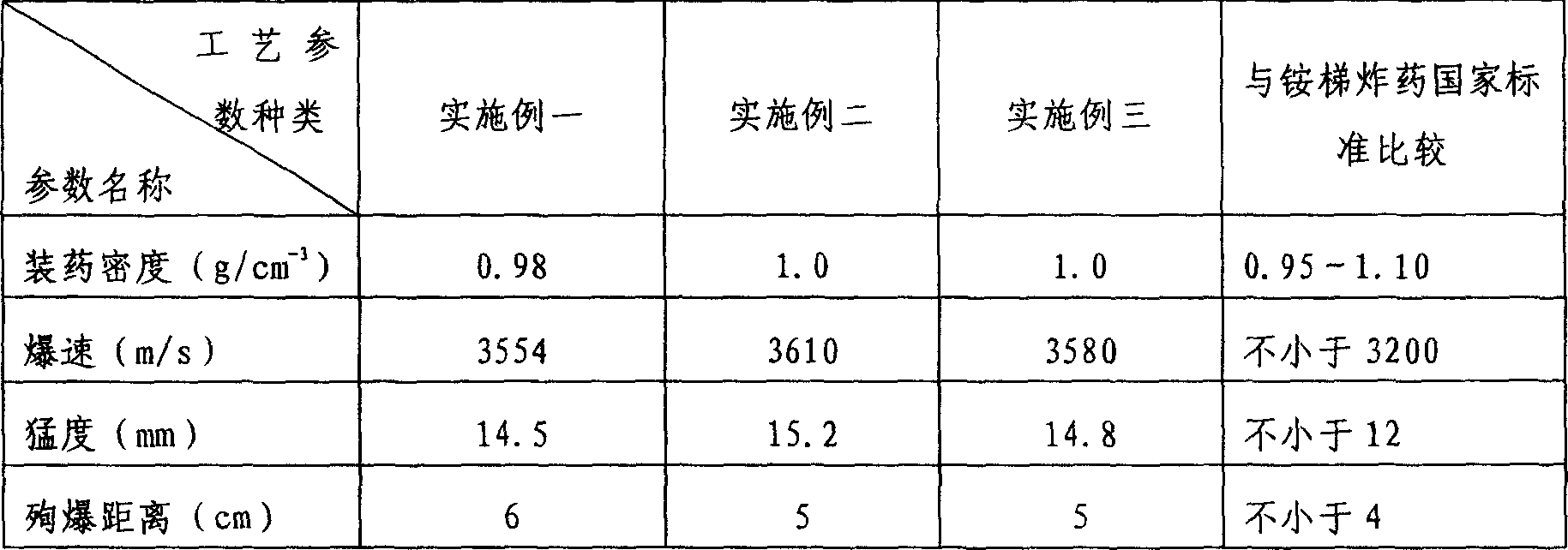

Examples

Embodiment 1

[0010] Get 750kg ammonium nitrate, add 75kg water, when heating to 115 ℃, add 1.125kg surfactant, surfactant is the mixture of octadecylamine acetate, stearic acid and sorbitan monolaurate, continue Heating, when the temperature of the material rises to 130°C, pump it into a crystallization tank with a vacuum degree of -0.088MPa to pass the material to crystallize, and the temperature of the crystallized expanded ammonium nitrate is controlled at 100°C; the prepared expanded ammonium nitrate is mixed with 190kg of unexpanded Ammonium nitrate fine powder is blended, 95% of unexpanded ammonium nitrate fine powder is passed through a 40-mesh sieve, and 30kg of oil phase and 30kg of wood flour are added. The oil phase is light diesel oil, 35 # The mixture of mechanical oil and paraffin was mixed for 20 minutes, and the discharging temperature was controlled at 65° C. to obtain 1000 kg of expanded ammonium nitrate explosive.

Embodiment 2

[0012] Take 700kg of ammonium nitrate, add 56kg of water, when heated to 100°C, add 1.05kg of surfactant, the surfactant is a mixture of sodium lauryl sulfate and sodium methanesulfonate, continue heating until the temperature of the material rises to 120°C , pumped to a crystallization tank with a vacuum degree of -0.092MPa for crystallization, and the temperature of the crystallized expanded ammonium nitrate was controlled at 95°C; the prepared expanded ammonium nitrate was blended with 200kg of unexpanded ammonium nitrate fine powder, without expansion 90% of ammonium nitrate fine powder is passed through a 40 mesh sieve, and 50kg of oil phase and 50kg of wood flour are added, and the oil phase is 40 # The mixture of machine oil and ozokerite was mixed for 10 minutes, and discharged, and the discharge temperature was controlled at 55° C. to obtain 1000 kg of expanded ammonium nitrate explosive.

Embodiment 3

[0014] Take 720kg of ammonium nitrate, add 65kg of water, when heated to 110°C, add 1.08kg of surfactant, the surfactant is a mixture of octadecylamine carboxylate and stearic acid, continue heating until the temperature of the material rises to 125°C , pumped to a crystallization tank with a vacuum degree of -0.090MPa to pass material crystallization, and the temperature of the crystallized expanded ammonium nitrate was controlled at 90°C; the prepared expanded ammonium nitrate was blended with 200kg of unexpanded ammonium nitrate fine powder, without 93% of ammonium nitrate fine powder is passed through a 40 mesh sieve, and 40kg of oil phase and 40kg of wood powder are added. The oil phase is heavy diesel oil, 40 # The mixture of mechanical oil and paraffin was mixed for 15 minutes, and the discharge was carried out. The discharge temperature was controlled at 60° C. to obtain 1000 kg of expanded ammonium nitrate explosive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com