Calorimeter for bucket cover with closed circulation tube temperature control mechanism

A closed loop and calorimeter technology, applied in the field of calorimeters, can solve the problems of uncertain intensity, unrealistic, and poor reproducibility, and achieve the effects of enhanced stirring, strong reproducibility, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

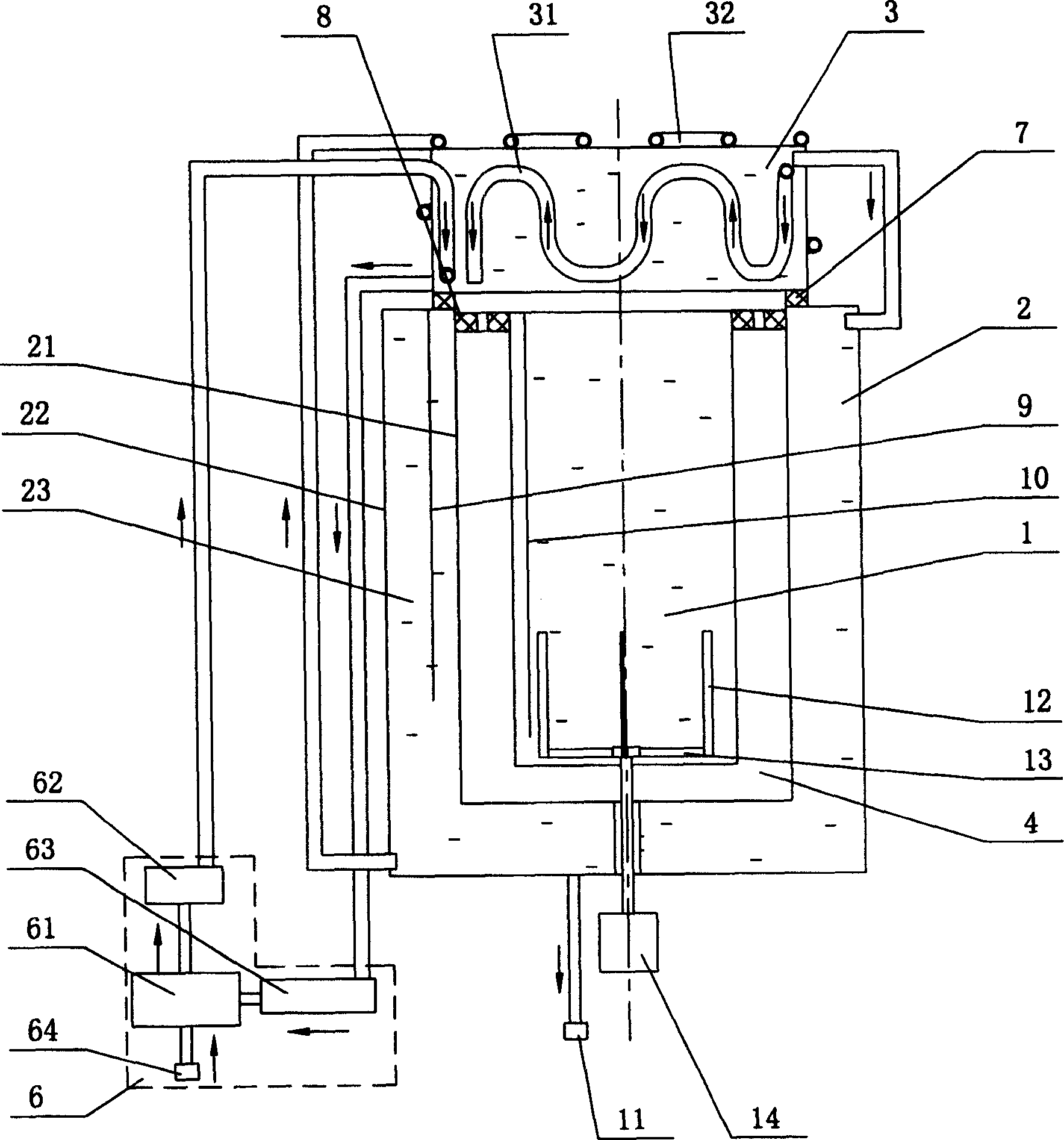

[0037] Embodiment 1: as figure 1As shown, a calorimeter with a closed loop temperature control mechanism in the lid of the present invention includes an inner barrel 1, an outer barrel 2 and a barrel lid 3 arranged on the top of the inner barrel 1 and the outer barrel 2, and the inner barrel 1 is placed in the outer barrel In 2, an outer barrel cavity 23 filled with a medium is formed between the outer side wall 22 and the inner side wall 21 of the outer barrel 2, and the medium can be liquid substances such as water and oil or other gaseous fluids; the inner barrel 1 and the outer barrel 2 There is an air interlayer 4 between them, the bung 3 is provided with a bung inner circulation pipe 31, the outer wall of the bung 3 is provided with a bung outer circulation pipe 32, the bung inner circulation pipe 31, the bung outer circulation pipe 32 and The circulation supply device 6 forms a closed-circuit circulation management and temperature control mechanism. The circulation sup...

Embodiment 2

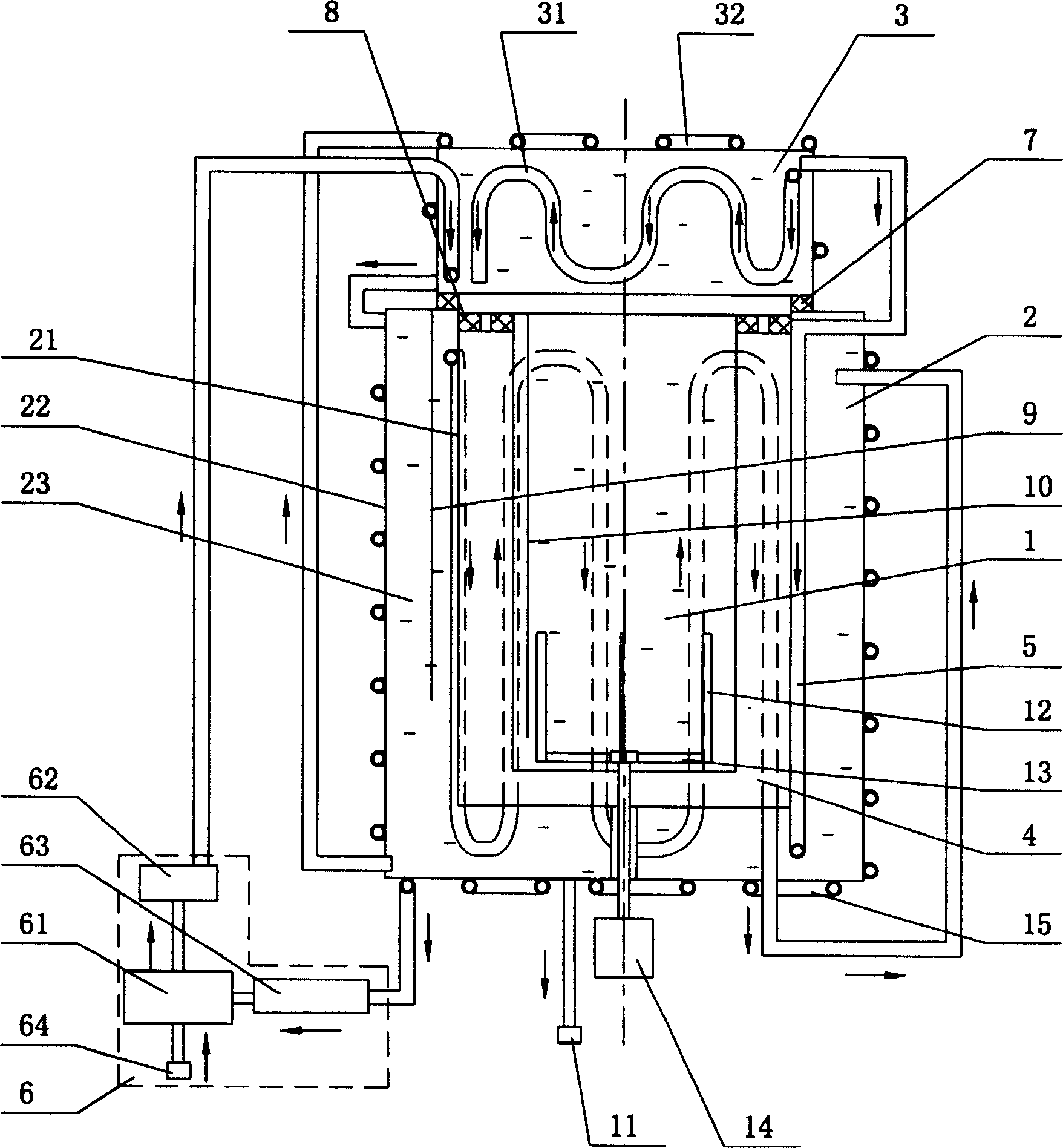

[0039] Embodiment 2: as figure 2 As shown, a calorimeter with a closed loop temperature control mechanism in the lid of the present invention includes an inner barrel 1, an outer barrel 2 and a barrel lid 3 arranged on the top of the inner barrel 1 and the outer barrel 2, and the inner barrel 1 is placed in the outer barrel 2, an outer barrel cavity 23 filled with medium is formed between the outer side wall 22 and the inner side wall 21 of the outer barrel 2, an air interlayer 4 is provided between the inner barrel 1 and the outer barrel 2, and an outer barrel cavity 23 is provided with an outer barrel cavity 23. Circulation pipe 5 in the barrel, outer barrel outer circulation pipe 15 is provided on the outer wall 22 of the outer barrel 2, inner circulation pipe 31 of the barrel lid 3 is arranged on the outer wall of the barrel lid 3, and outer circulation pipe of the barrel lid is installed on the outer wall of the barrel lid 3 32. The inner circulation pipe 5 of the outer ...

Embodiment 3

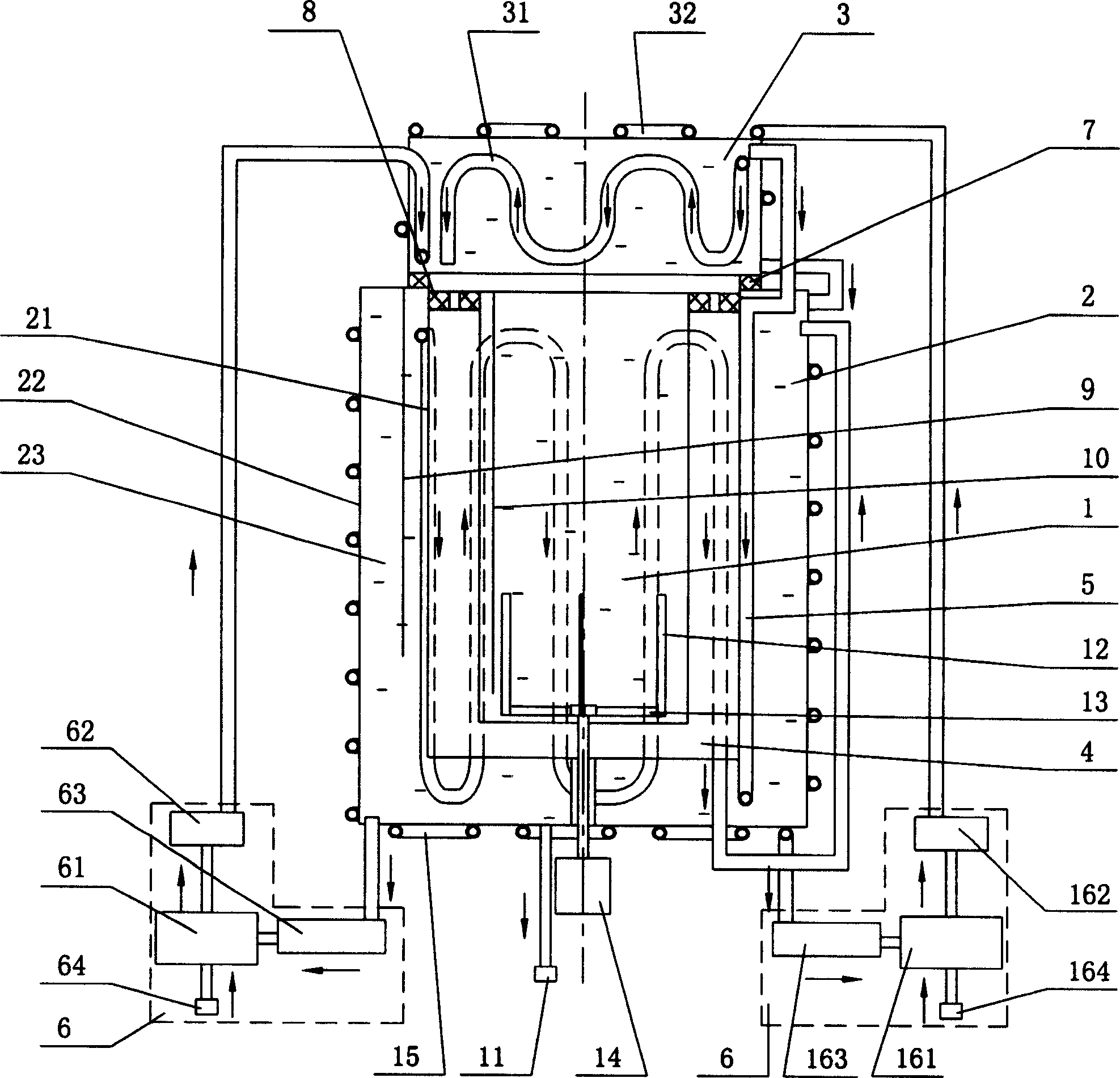

[0041] Embodiment 3: as image 3As shown, a calorimeter with a closed loop temperature control mechanism in the lid of the present invention includes an inner barrel 1, an outer barrel 2 and a barrel lid 3 arranged on the top of the inner barrel 1 and the outer barrel 2, and the inner barrel 1 is placed in the outer barrel 2, an outer barrel cavity 23 filled with medium is formed between the outer side wall 22 and the inner side wall 21 of the outer barrel 2, an air interlayer 4 is provided between the inner barrel 1 and the outer barrel 2, and an outer barrel cavity 23 is provided with an outer barrel cavity 23. Circulation pipe 5 in the barrel, outer barrel outer circulation pipe 15 is provided on the outer side wall 22 of the outer barrel 2, inner circulation pipe 31 of the barrel lid 3 is arranged on the outer side wall of the barrel lid 3, and outer circulation of the barrel lid is arranged on the outer side wall of the barrel lid 3 Pipe 32, outer barrel inner circulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com