Cream, ointment soap containing refined and purified bamboo vinegar liquid

A technology of bamboo vinegar liquid and bamboo vinegar soap, which is applied in the field of washing products and nursing care, can solve the problems of side effects of users, difficulty in controlling the quality of finished products, etc., and achieve the effect of simple method and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

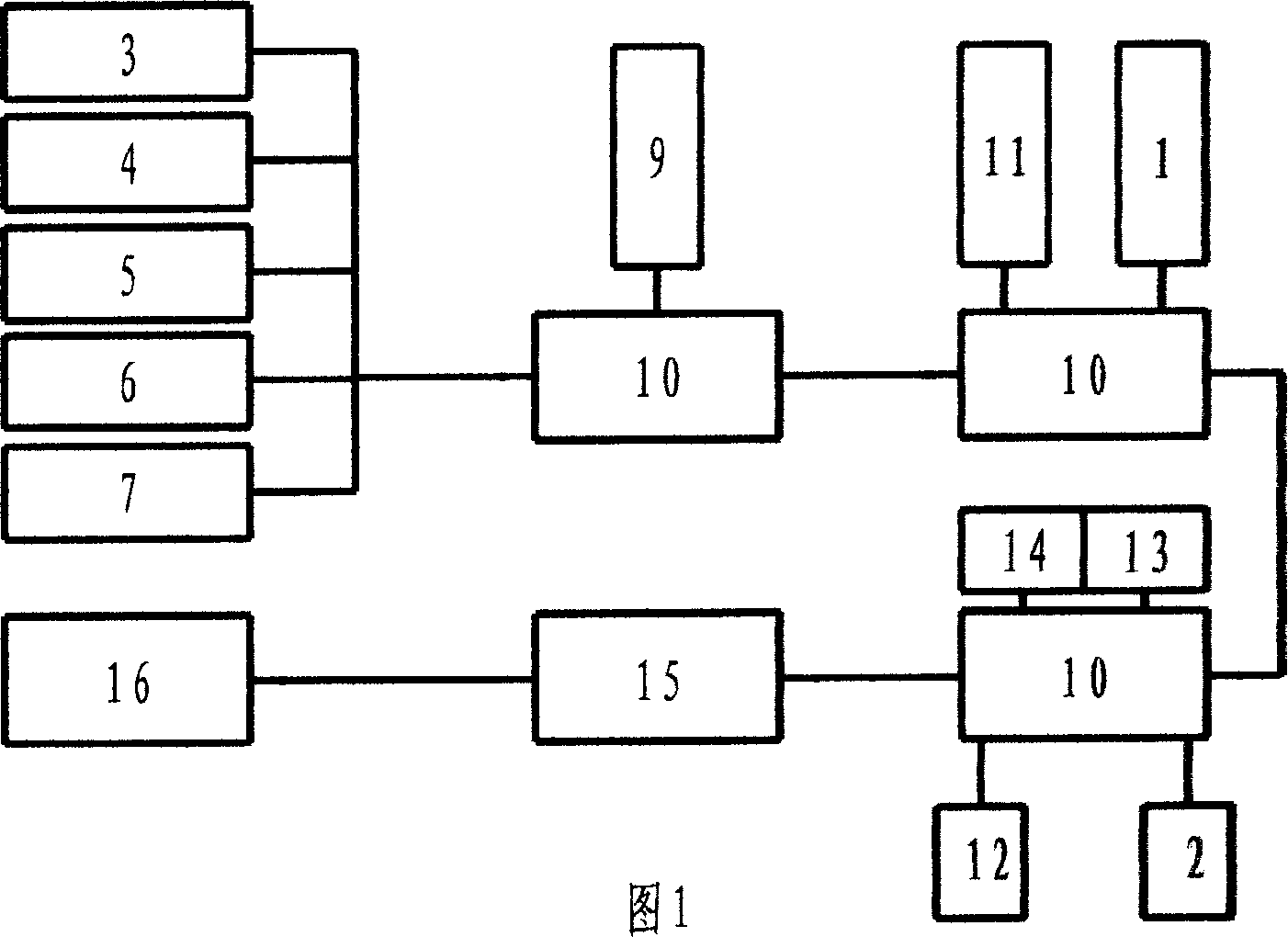

[0018] According to the raw material ratio requirements of the product, deionized water 3, nutrients 4, lipid chemical raw materials 5, alcohol chemical raw materials 6, and other chemical raw materials 7 are put into the reaction kettle 10 in proportion and stirred evenly, and Heating 9 to process temperature during the process, until the chemical reaction in the reactor 10 is completed, then in the process of reducing the temperature 11 in the reactor 10, add purified bamboo vinegar liquid 1 (purified bamboo vinegar liquid 1 high temperature is easy to decompose) Continue to stir evenly, and when the temperature drops to a certain value, add volatile and decomposed preservatives, flavors 13, and pigments 14, continue to stir evenly, and add PH regulator 2 while checking during the stirring process until it reaches Product qualification requirements, through the filtering and packaging process 15, the finished product 16 is obtained.

[0019] Such as figure 2 Shown is the pr...

Embodiment 2

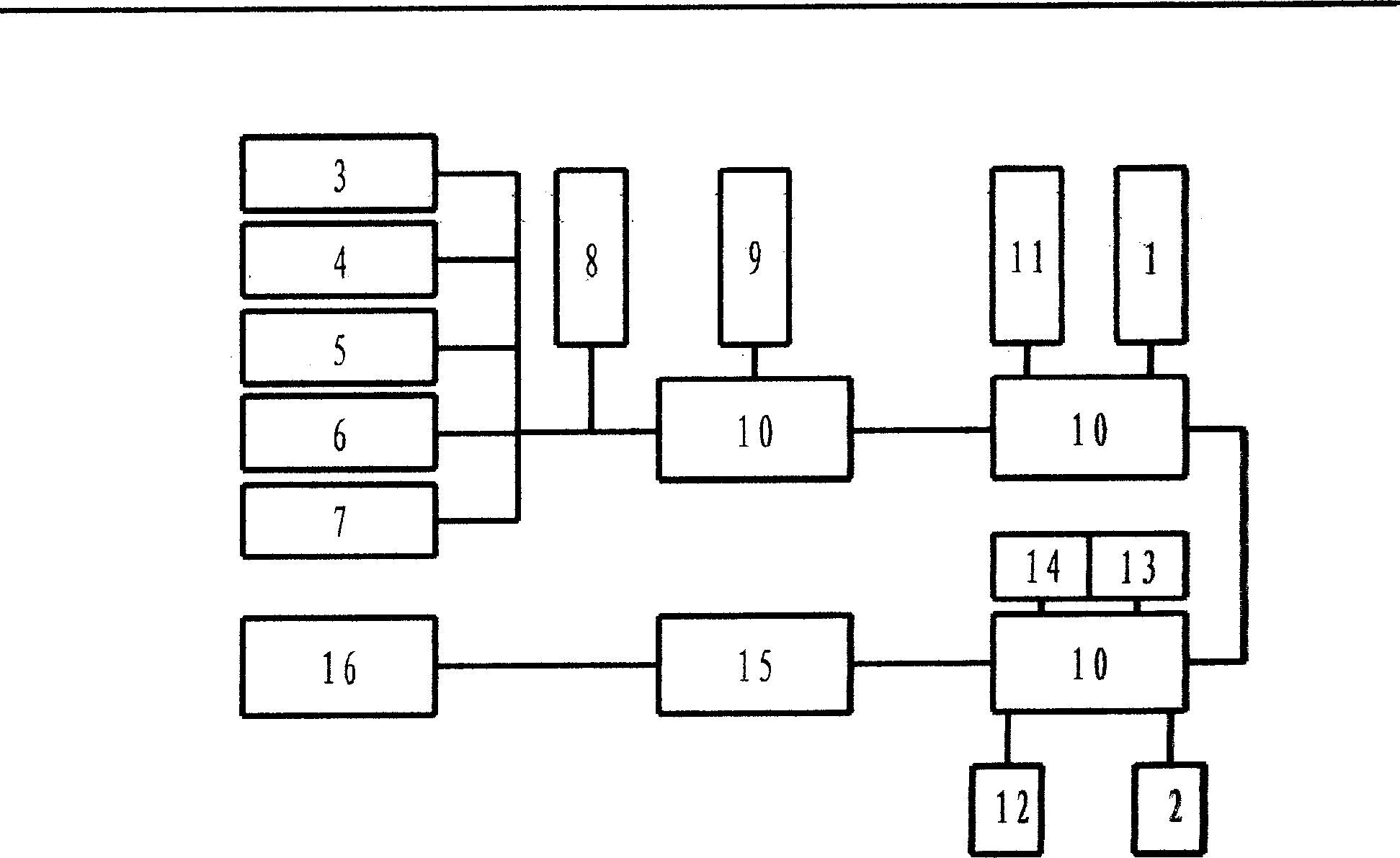

[0021] According to the raw material ratio requirements of the product, deionized water 3, nutrients 4, lipid chemical raw materials 5, alcohol chemical raw materials 6, other chemical raw materials 7, pottery clay, talcum powder, kaolin (one or two materials in ) 8, put into the reaction kettle 10 in proportion and stir evenly, and heat 9 to process temperature in the process of stirring, until the chemical reaction in the reaction kettle 10 is completed, then reduce the process of temperature 11 in the reaction kettle 10 Add purified bamboo vinegar solution 1 (purified bamboo vinegar solution 1 is easy to decompose at high temperature) and continue to stir evenly. When the temperature drops to a certain value, add volatile and decomposed preservatives, essences 13, pigments 14, and continue to stir Evenly, add pH adjuster 2 while inspecting in the process of stirring until the qualified product requirements are met, and pass through the filtering and packaging process 15 to o...

Embodiment 3

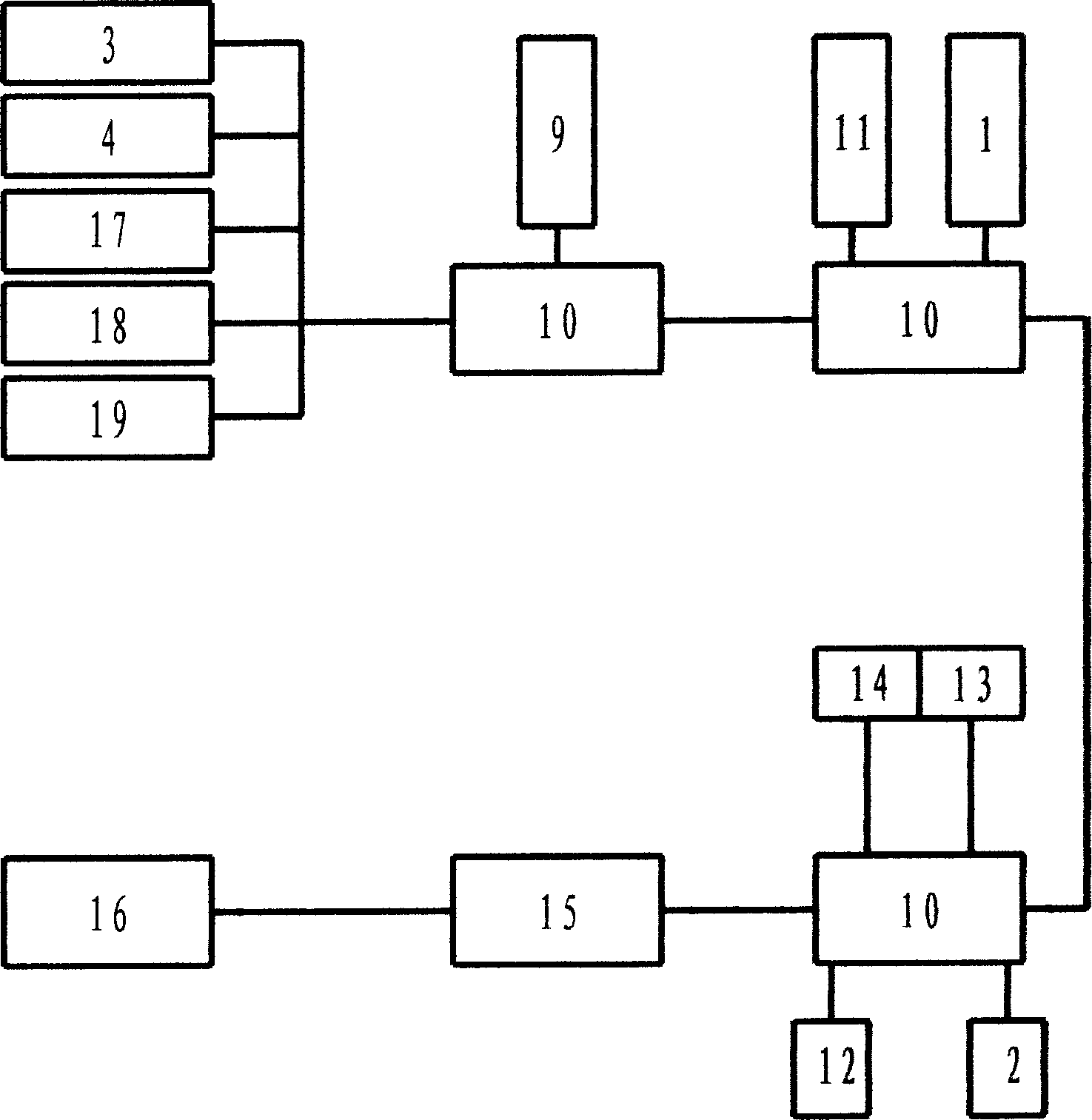

[0023] image 3 It is a production flow chart composed of production equipment and production process when using purified bamboo vinegar to replace part of artificially synthesized industrial chemicals to produce soap products.

[0024] According to the raw material ratio requirements of the product, deionized water 3, nutrients 4, soap base 17, chelating agent 18, sugar, glycerin, ethanol polytitanium and other raw materials (add as needed) 19, (optional amount of original Antioxidant, preservative, NaCl or KCl 20), put into the reactor 10 in proportion and stir evenly, and heat 9 to process temperature in the process of stirring, until the chemical reaction in the reactor 10 is completed, then in In the process of reducing the temperature 11 in the reactor 10, add purified bamboo vinegar liquid 1 (purified bamboo vinegar liquid 1 high temperature is easy to decompose) and continue to stir evenly, when the temperature drops to a certain value, add volatile, decomposed preserv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com