Hub dynamo

A technology for in-wheel motor and magnetic flux collection, which is applied to synchronous machines, electromechanical devices, electrical components, etc., can solve the problems of weak support strength and magnetic flux saturation of the support part, achieve better performance, reduce magnetic saturation, and achieve smaller diameters Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

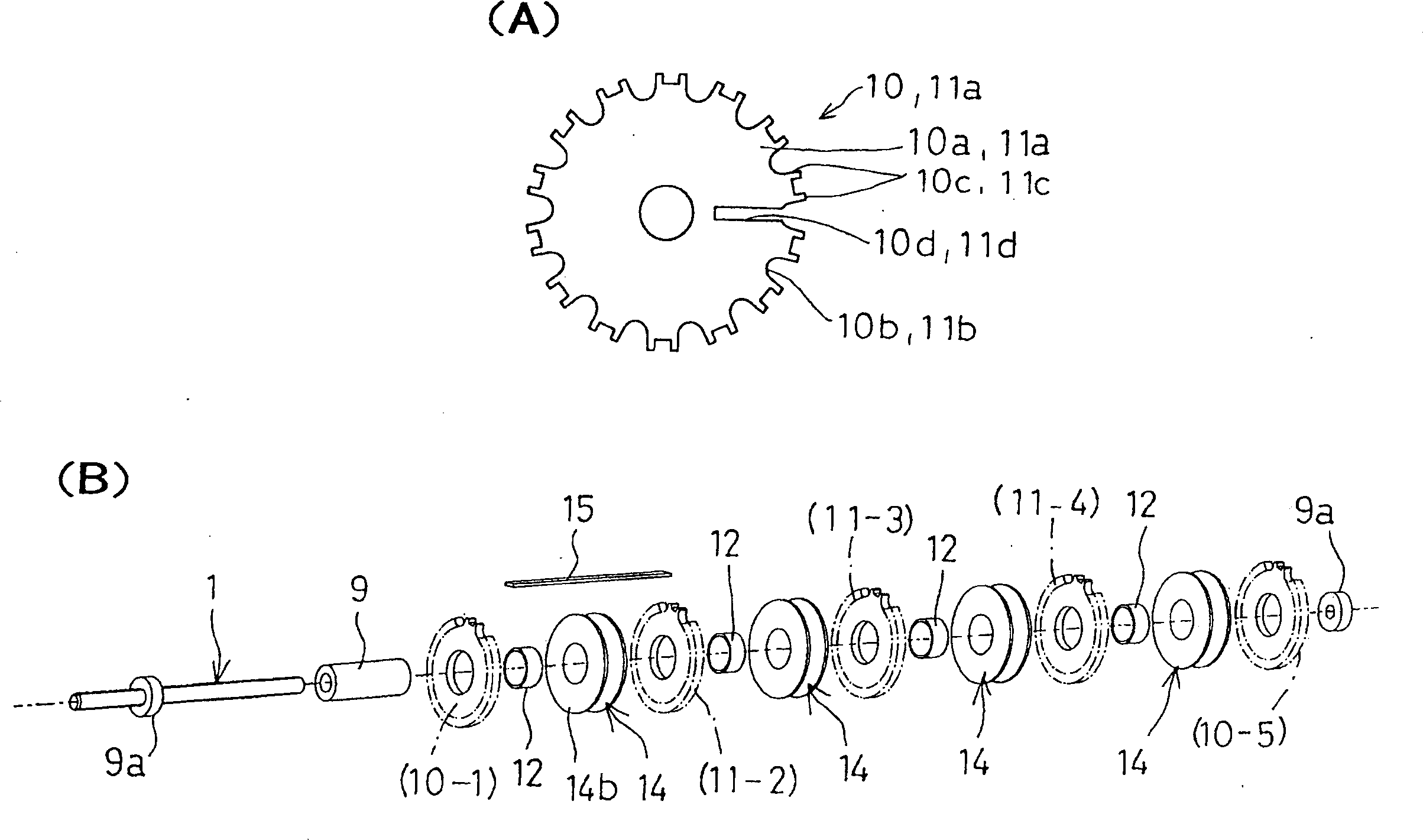

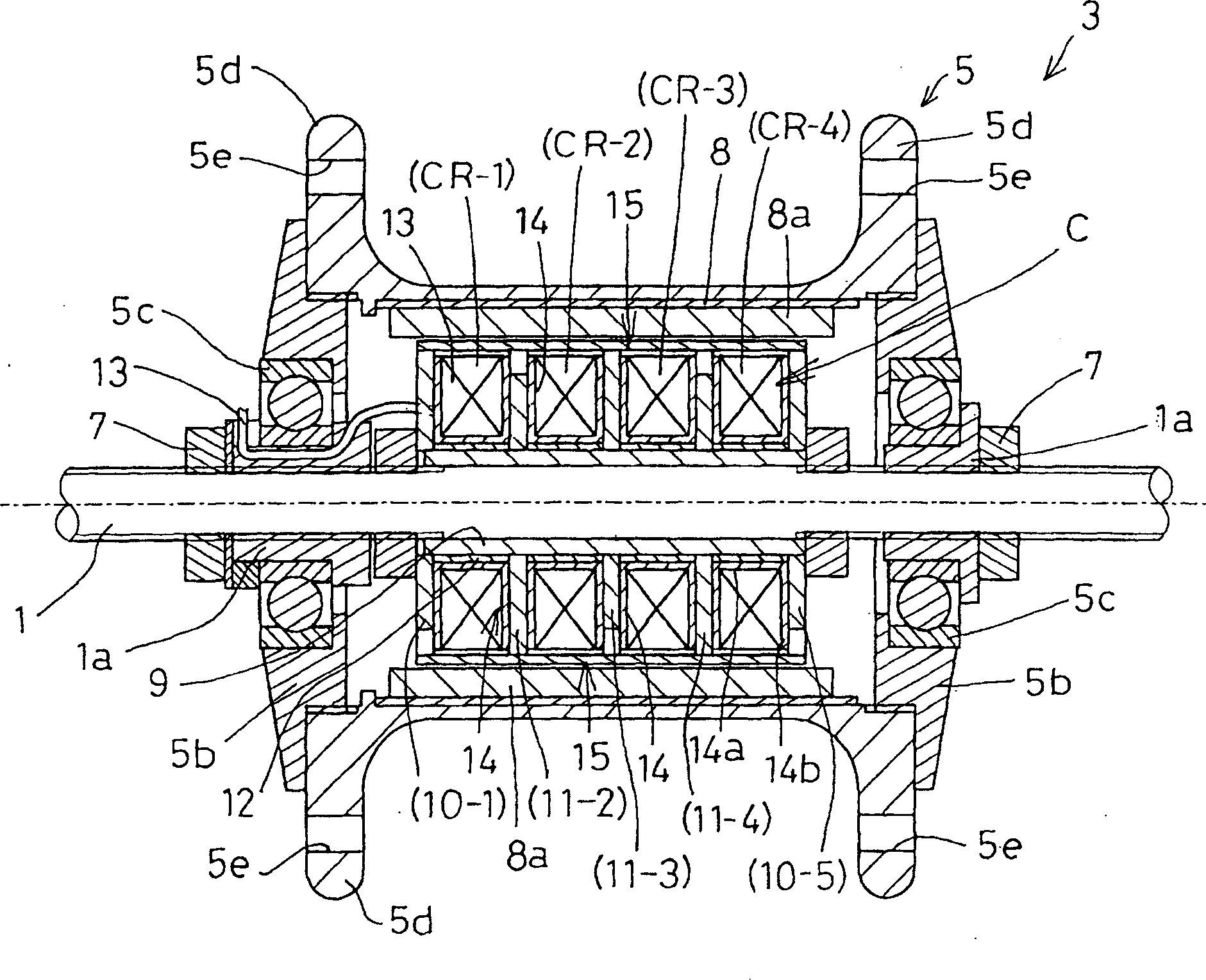

[0045] Next, a first embodiment of the present invention will be described with reference to the drawings.

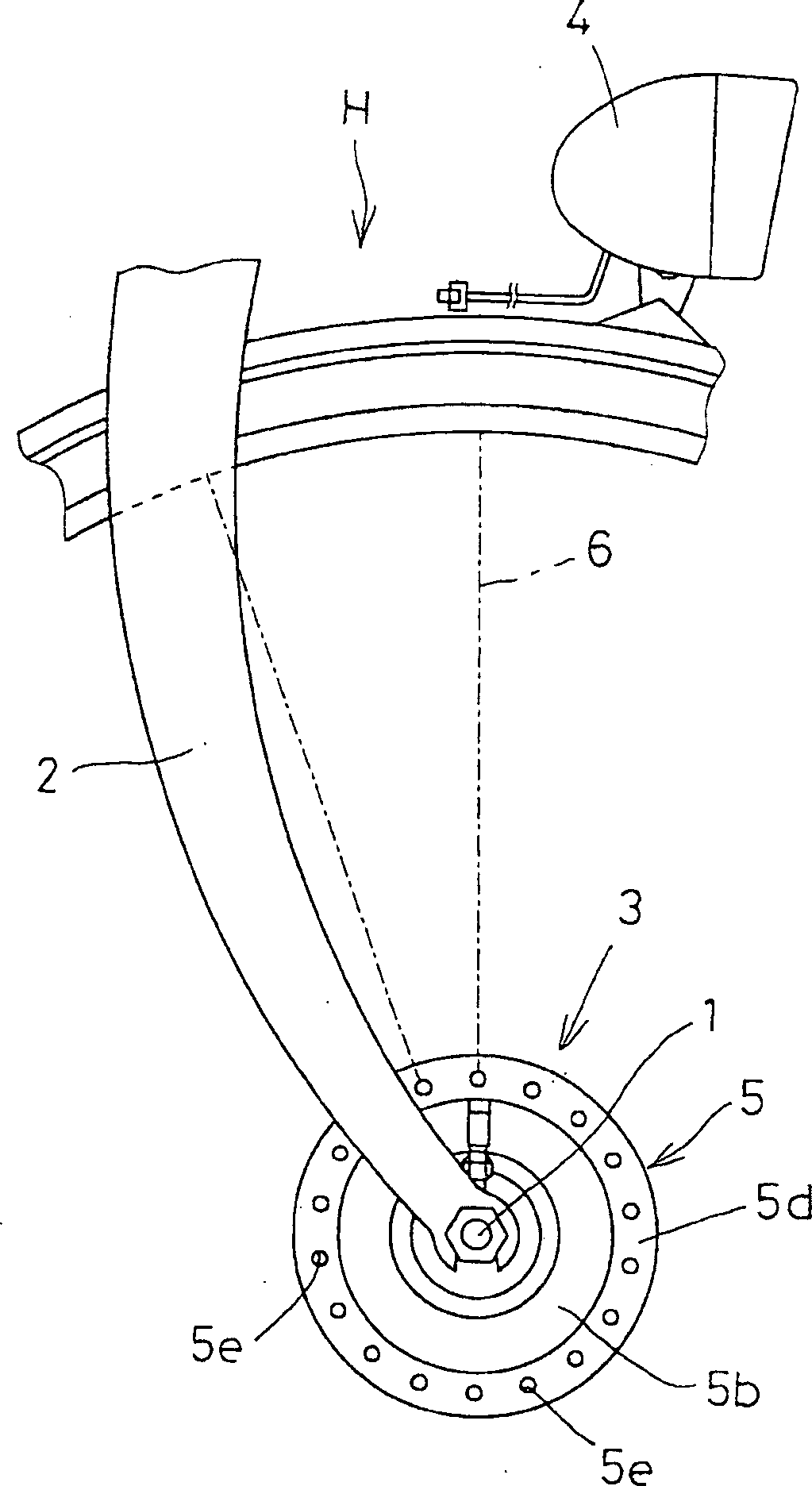

[0046] In the drawings, 1 is an axle constituting the rotation center of a front wheel (front wheel) H of a bicycle. The left and right ends of the axle 1 are supported by a pair of left and right front forks 2 constituting the vehicle body. The hub motor 3 implemented by the present invention is equipped with on the axle shaft 1.

[0047] In addition, 4 is a headlight connected so as to be lit by receiving electric power from the in-wheel motor 3 .

[0048] 5 is a casing (hub) constituting the in-wheel motor 3, and the casing 5 is integrally arranged by a cylindrical body portion 5a on which the axle 1 is fitted, and a cylindrical opening formed at both axial ends of the body portion 5a. A left and right pair of tailstocks 5b constitutes. The tailstock 5b is made of a ring-shaped plate, and is provided through a bearing 5c provided on the outer periphery of a bush ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com