Dustpan-like sorting and impurity-removing device

A sorting and dustpan technology, used in solid separation, sieves, grilles, etc., can solve the problems of large area, high cost, poor sorting effect, etc., to reduce the area, reduce the cost and use The effect of energy consumption, ease of operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

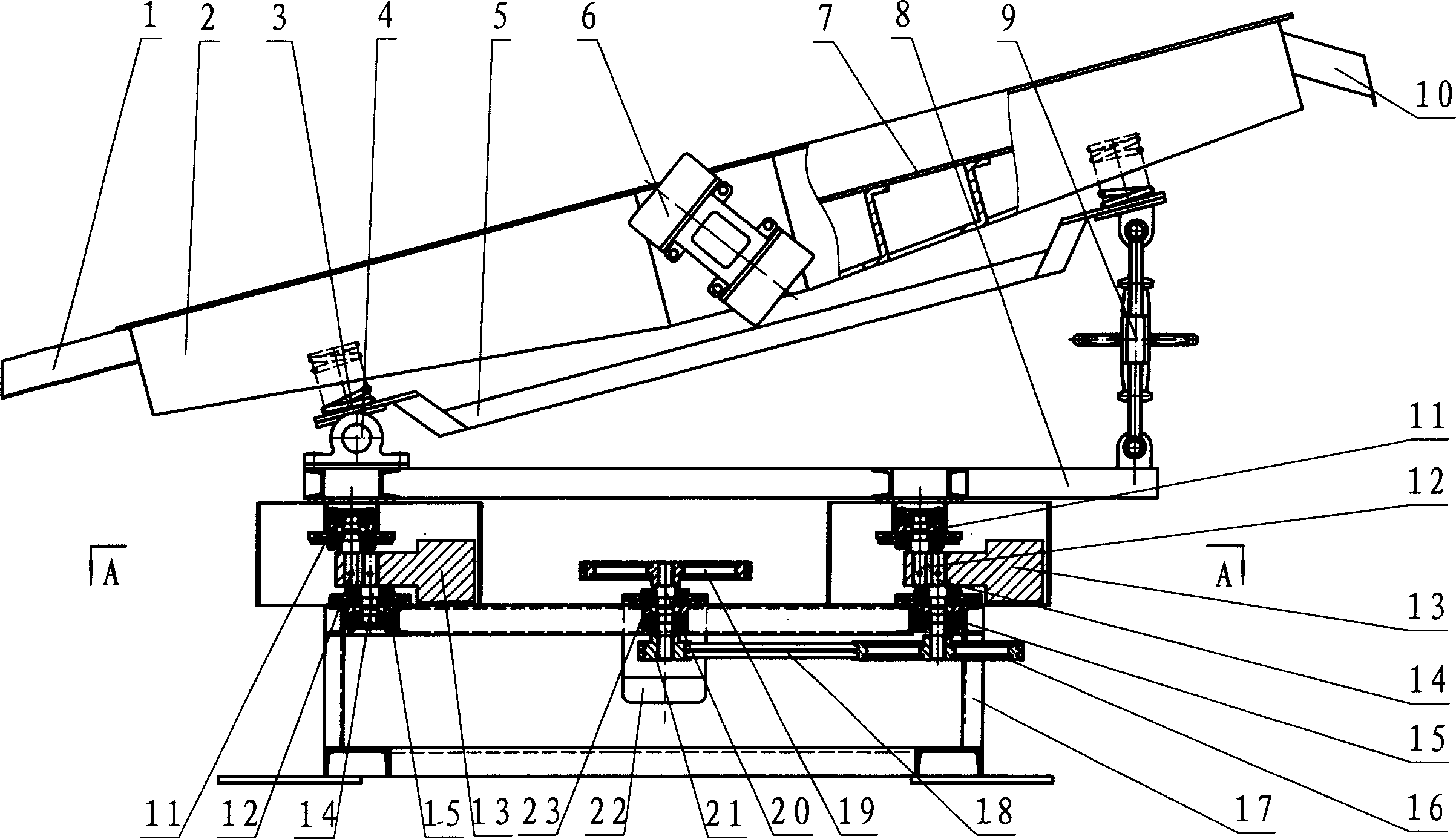

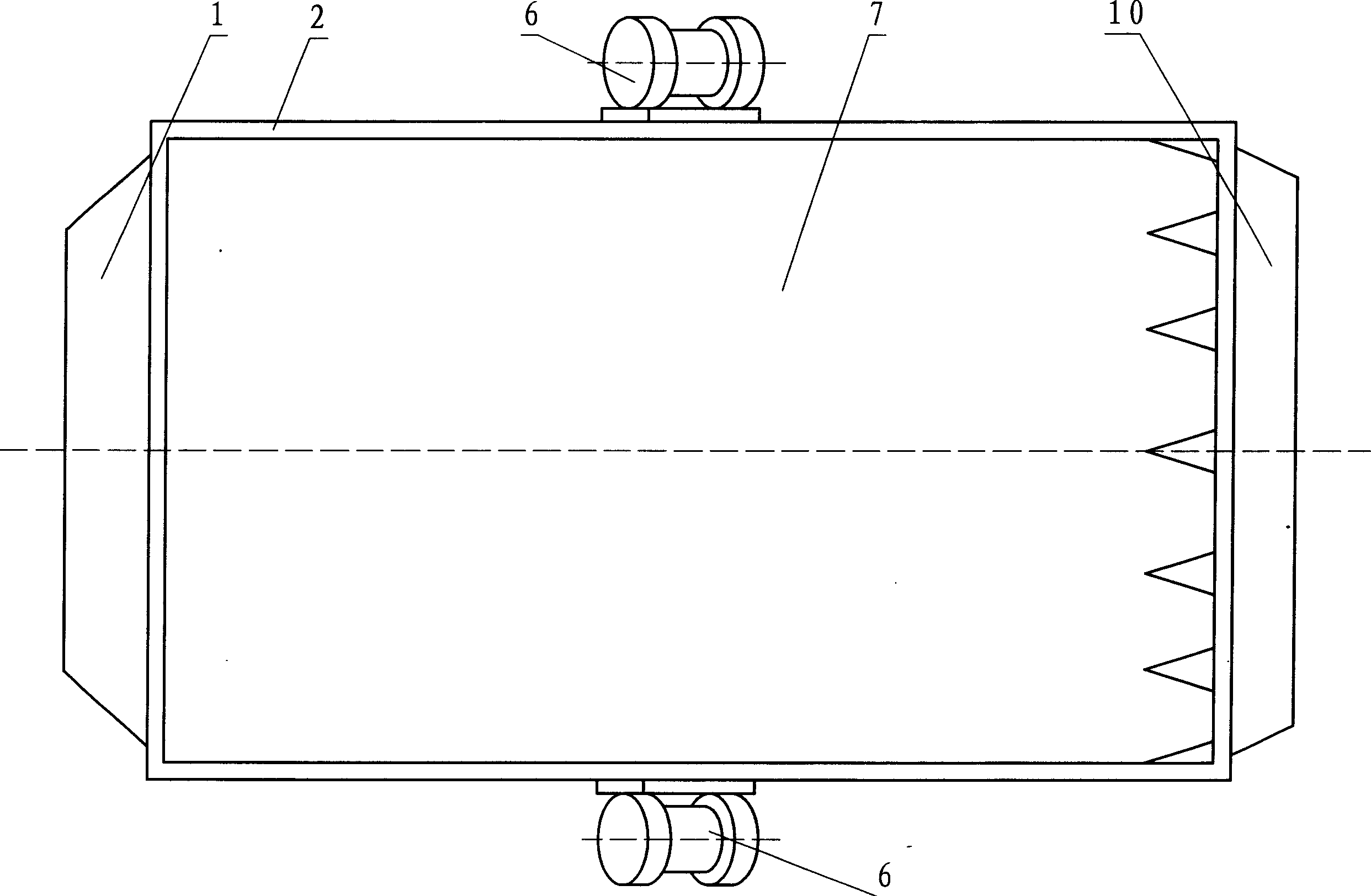

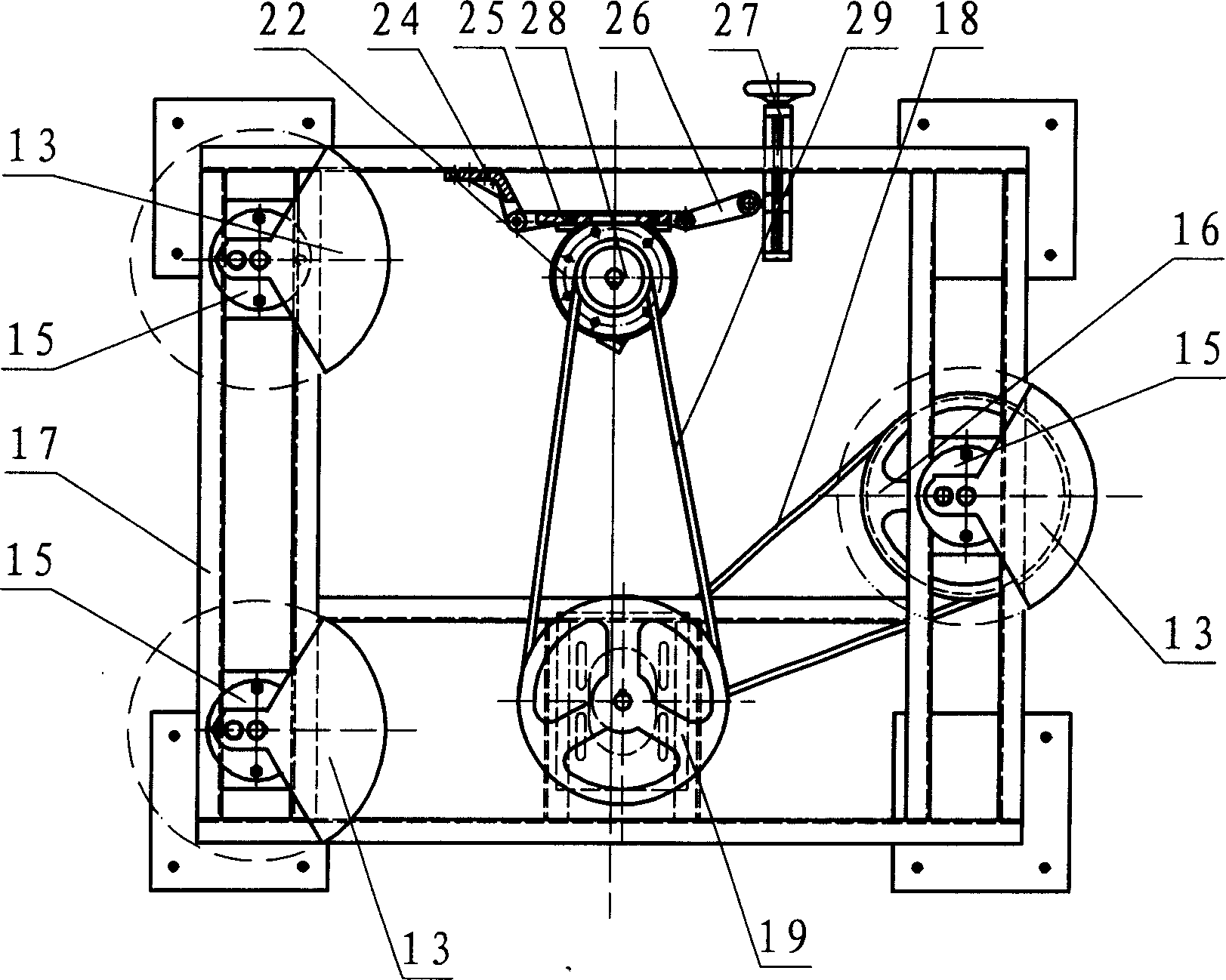

[0013] As shown in the drawings, the present invention includes a frame 17, a screen frame 5, a screen body 2 and an electric vibrator 6, and the frame 17 is welded with profiles, and the screen body 2 is a rectangular box. The body 2 is welded with steel plates; there is a fish scale sieve 7 in the sieve body 2, and the fish scale sieve 7 plays the role of sorting materials; at the front end of the sieve body 2 there is a discharge port 10 for kernels or grains. The rear end of the sieve body 2 has a discharge port 1 for unhulled grains, which discharges the sorted materials respectively; there are two electric vibrator 6, which are respectively installed on both sides of the sieve body 2, so that The sieve body 2 produces linear reciprocating oblique upward throwing motion; the sieve body 2 is installed on the sieve frame 5 through the elastic element 3, and the elastic element 3 is a set of coil springs, so that the sieve body 2 and the sieve frame 5 are elastically Connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com