On-line testing and analyzing device and method for microelectromechanical system component material parameter

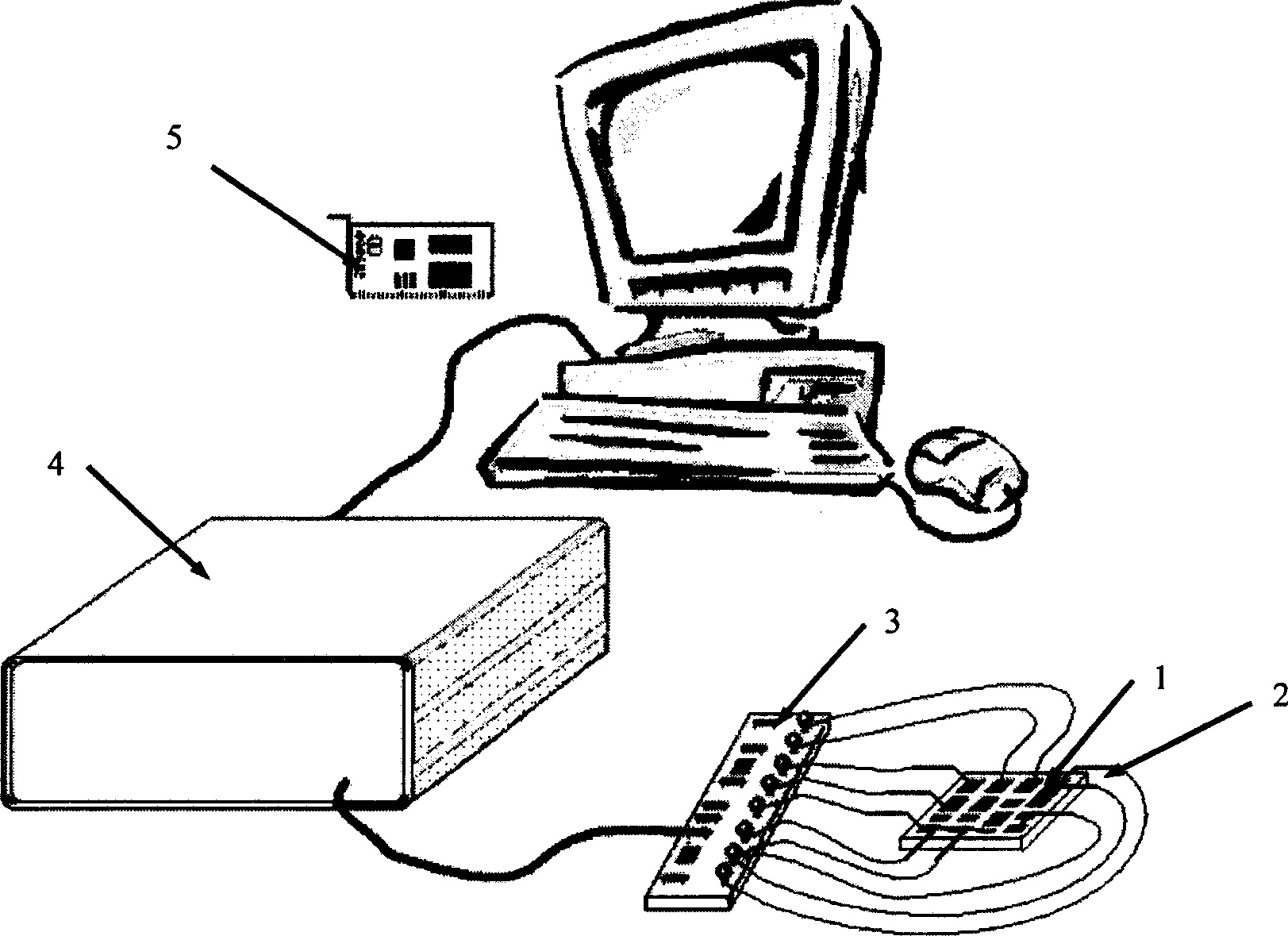

A technology of micro-electromechanical systems and material parameters, which is applied in the direction of analyzing materials and instruments, and can solve problems such as online testing of MEMS material parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

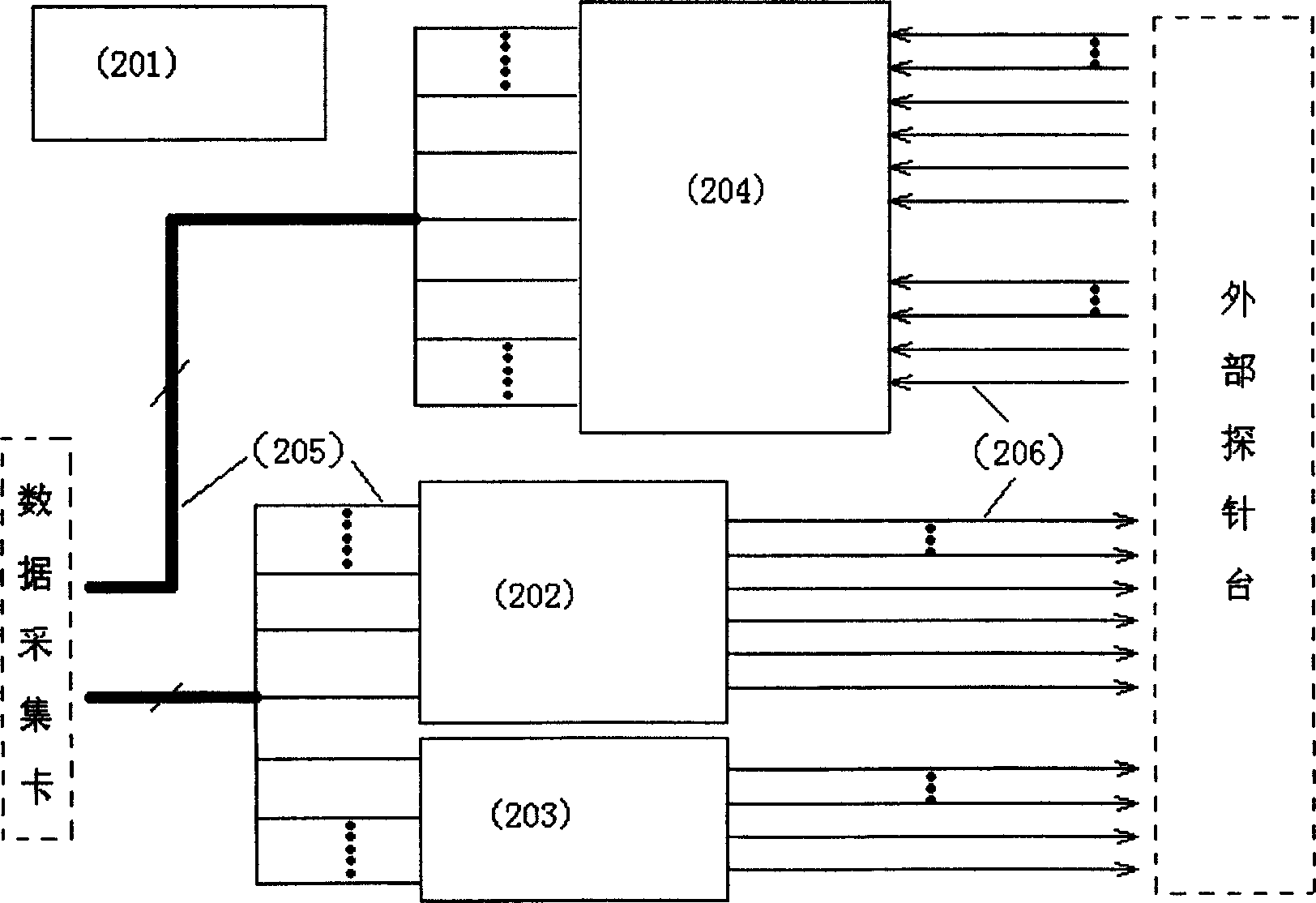

[0050] Specific implementation plan

[0051] According to the above-mentioned basic measurement method, combined with the specific test plan, it is necessary to design the test excitation signal and the design of the test output detection plan. The basic detection methods of test output can be roughly divided into: open circuit critical test; short circuit critical test; excitation-response relaxation test; direct voltage test; direct current test.

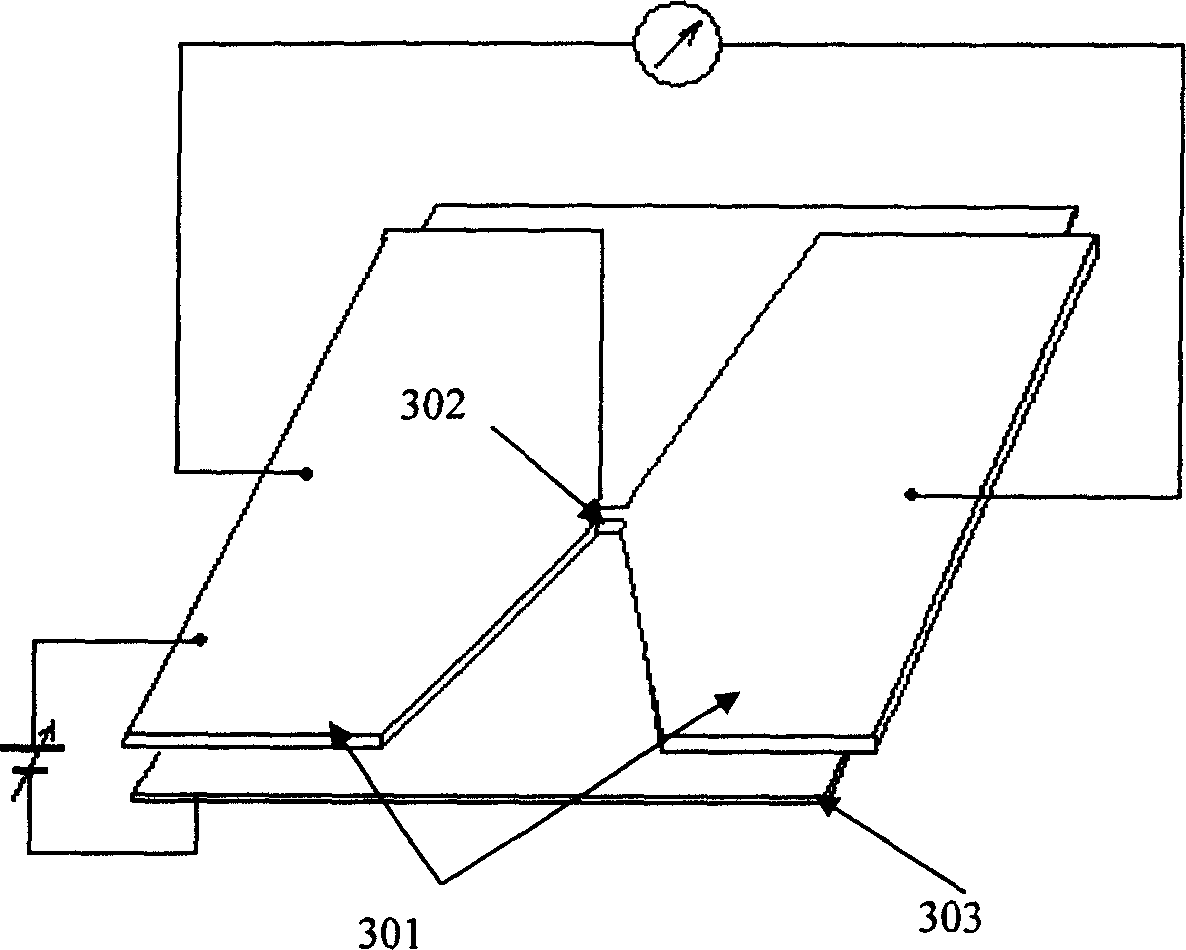

[0052] (1) Open circuit critical test

[0053] The so-called open-circuit criticality refers to continuously checking whether the test structure has an open circuit due to voltage or current while applying input voltage or current excitation. Once an open circuit occurs, record the excitation voltage or current value at the critical open circuit and calculate it as a substitution model Parameters.

[0054] Here we take the measurement of the breaking strength of the material as an example to illustrate the measurement plan. There are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com