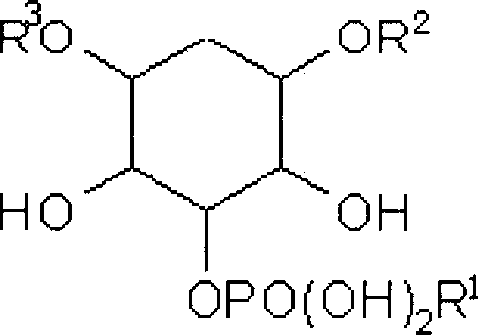

Method for preparing ammonium salts of cyclohexanpentol phosphate ester

A technology of ammonium cyclohexapentyl phosphate and cyclohexapentyl phosphate, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problem of polyol phosphate Ammonium salt report, no preparation method and report of cyclohexapentyl phosphate ammonium salt, achieve the effects of low pollution, common and easy-to-obtain raw materials, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

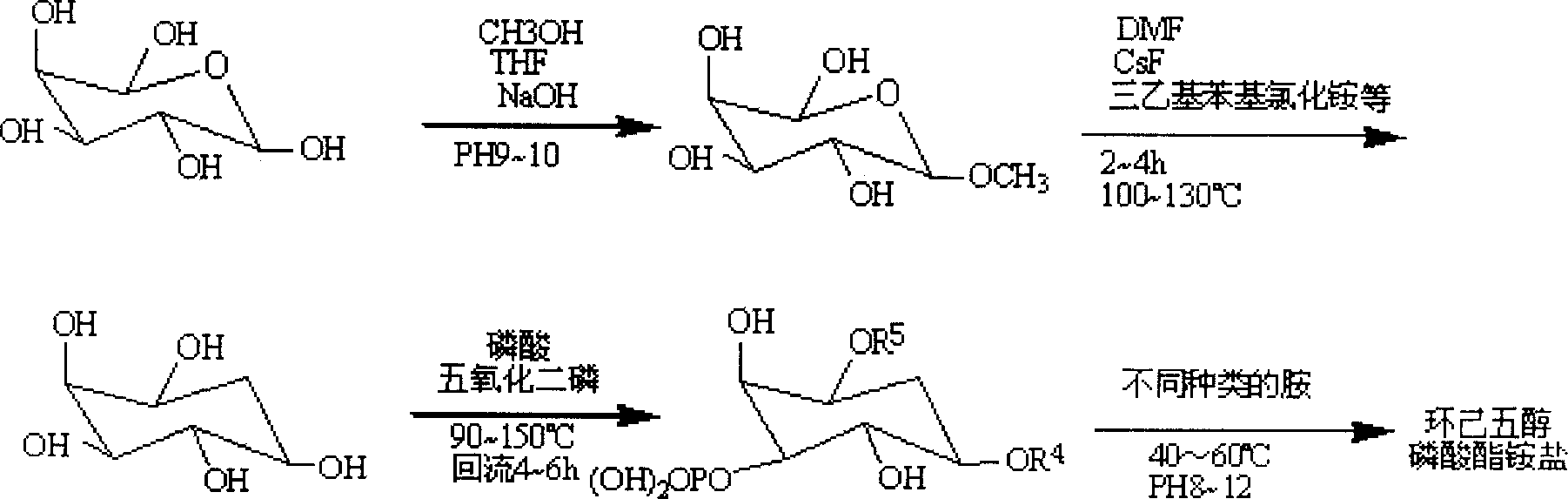

[0024] Prepare cyclohexapentyl phosphate N-hydroxysucciniminium salt by the method of this embodiment, comprising the following steps:

[0025] (1) Synthesis of cyclohexanepentaol: add about 6g of glucose, 2ml of methanol, and 20ml of THF into a three-necked flask; add 2ml of concentrated sulfuric acid dropwise under stirring, continue stirring for about 4 hours after dropping, and adjust the reaction mixture with 40% NaOH aqueous solution pH value to 9-10, filter off the precipitated white solid, distill off THF; use CHCl 3 Extract 3 times, each time with CHCl 3 About 80ml, combine the extracts, add appropriate amount of K 2 CO 3 to dry; then distill off CHCl 3 , the residue was separated by silica gel column chromatography, and CHCl 3 As a eluting agent, the obtained eluent is desolvated to obtain a viscous substance, namely methyl glucoside. Add 30mlDMF to methyl glucoside, use appropriate amount of CsF and triethylphenyl ammonium chloride as catalyst, realize phase tr...

Embodiment 2

[0029] Prepare tricyclohexapentyl phosphate N-hydroxysucciniminium salt by the method of this embodiment, comprising the following steps:

[0030] (1) Synthesis of cyclohexanepentol: Add 5.72g of glucose, 2ml of methanol, and 20ml of THF into a three-necked flask; add 2ml of concentrated sulfuric acid dropwise under stirring, continue stirring for about 3h after dropping, and adjust the reaction mixture with 40% NaOH aqueous solution pH value to 9-10, filter off the precipitated white solid, distill off THF; use CHCl 3 Extract 3 times, each time with CHCl 3 About 70ml, combine the extracts, add appropriate amount of K 2 CO 3 to dry; then distill off CHCl 3 , the residue was separated by silica gel column chromatography, and CHCl 3 As a eluting agent, the obtained eluent is desolvated to obtain a viscous substance, namely methyl glucoside. Add 30ml DMF to methyl glucoside, use appropriate amount of CsF and triethylphenylammonium chloride as catalyst to realize phase transfer...

Embodiment 3

[0034] Prepare diisopropylammonium cyclohexapentyl phosphate by the method of this embodiment, comprising the following steps:

[0035] (1), synthesis of cyclohexanepentaol: add 5g glucose, 2ml methanol, and 20ml THF to a three-necked flask; add 2ml concentrated sulfuric acid dropwise under stirring, continue stirring for about 3h after dropping, adjust the reaction mixture with 40% NaOH aqueous solution pH value to 9 ~ 10, filter off the precipitated white solid, distill off THF; use CHCl 3 Extract 2 times, each time with CHCl 3 About 70ml, add appropriate amount of K 2 CO 3 to dry; then distill off CHCl 3 , the residue was separated by silica gel column chromatography, and CHCl 3 As a eluting agent, the obtained eluent is desolvated to obtain a viscous substance, namely methyl glucoside. Add 30ml of DMF to methyl glucoside, and use appropriate amount of CsF and triethylphenyl ammonium chloride as catalyst to realize phase transfer catalysis, and obtain the intermediate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com