Adaptive optical system based on micro-prism sharck Harteman wave-front sensor

A technology of adaptive optics and microprism, which is used in measurement optics, optical radiation measurement, and testing optical performance, etc., to achieve the effect of simplified installation and adjustment, easy processing technology, and easy mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

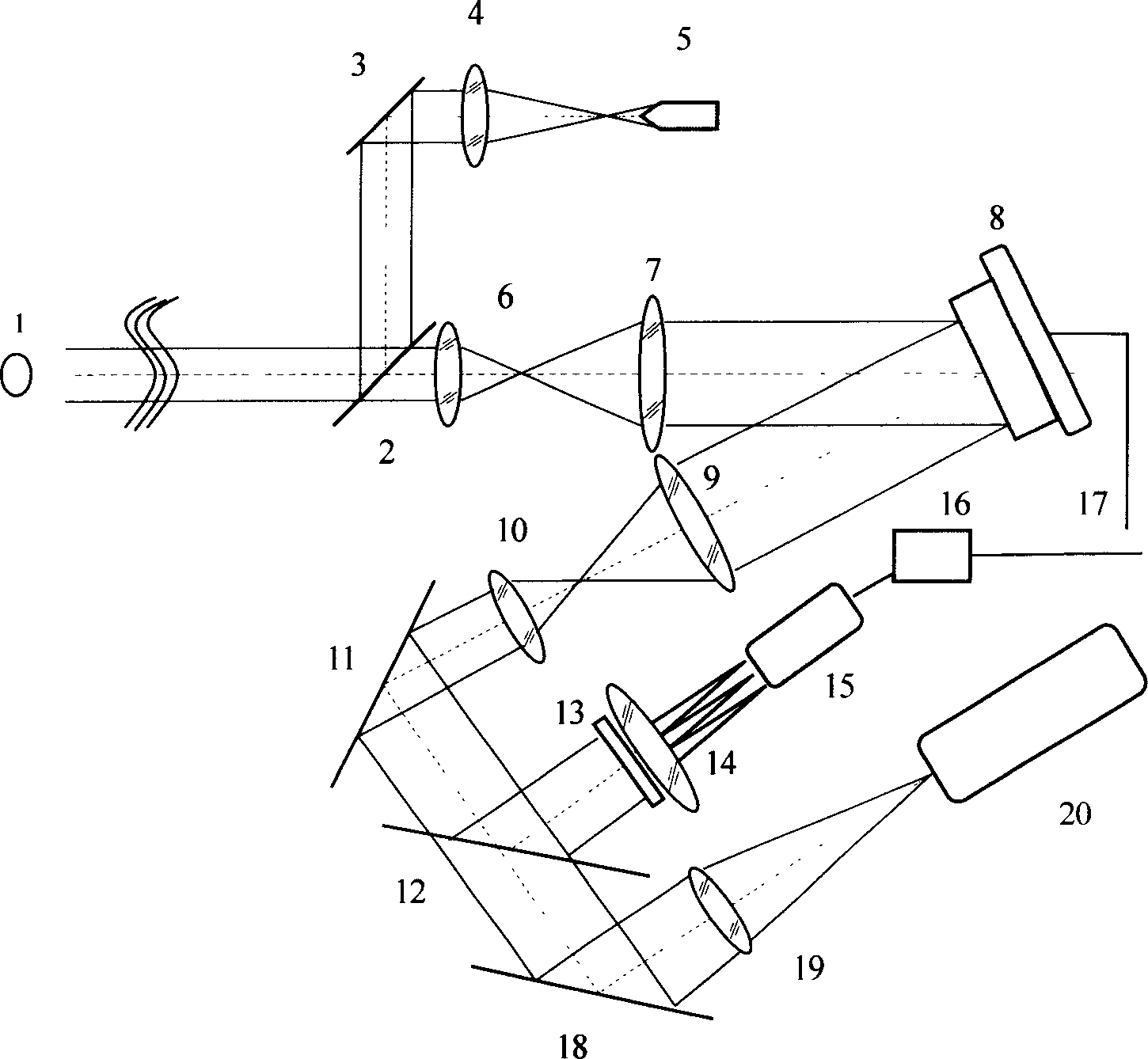

[0029] Such as figure 2As shown, the present invention includes mirrors 2, 3, 11, 12, 18, collimator lens 4, beacon light source 5, lenses 6 and 7 form a beam expander system, wavefront corrector 8, and lenses 9 and 10 form a beam shrinker System, a microprism array 13, a Fourier lens 14 close to it, and a photodetector 15 located on the focal plane of the Fourier lens form a microprism Shack-Hartmann wavefront sensor, a wavefront processor 16, a high-voltage amplifier 17, and a focusing lens 19, photodetector 20, the light emitted by the beacon light source 5 is collimated by the lens 4, and then irradiates the target object 1 after being reflected by the mirrors 2 and 3, and the beacon light 5 reflected by the target object 1 passes through the lenses 6 and 7 The formed beam expander system is reflected by the wavefront corrector 8, then passes through the beam shrinker system composed of lenses 9 and 10, and is reflected by the mirror 12 into the microprism Shack-Hartmann ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com