Power supply method of asynchronous machine

A power supply method and asynchronous motor technology, applied in the field of power electronics and power transmission, can solve the problems of increasing switching loss, stimulating audio noise, interfering with electronic equipment, etc., and achieve the effects of reduced switching noise, high torque and power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

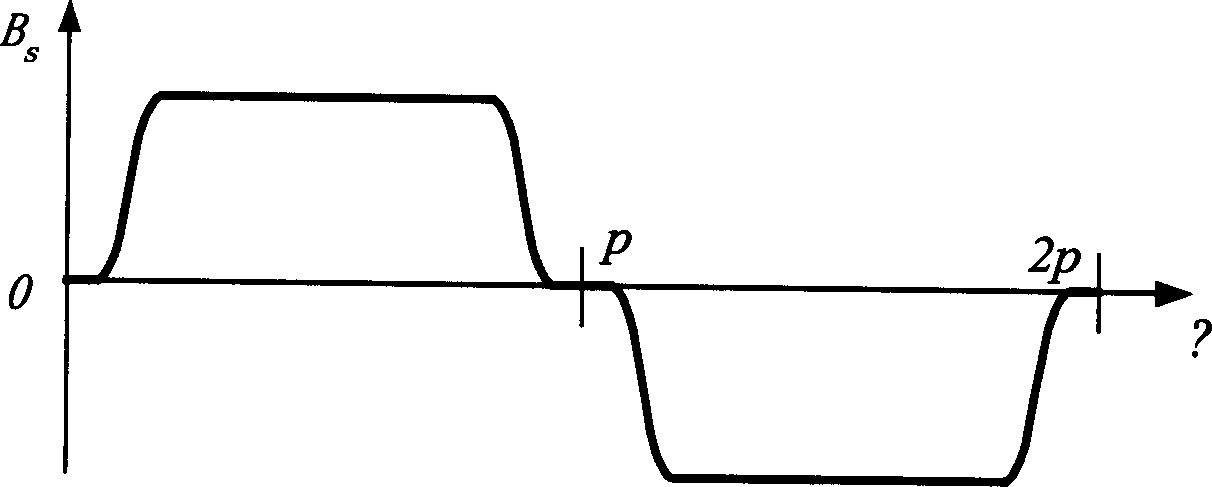

[0017] The technical solution of the present invention considers that the more the number of phases, the closer the magnetic field is to a square wave. Each pole of the existing three-phase asynchronous motor has three phase belts, and each phase has two or more than two slots. Each pole of the asynchronous motor of the present invention adopts m phase belts (m≥3, m may not be a multiple of 3), and each phase belt has only one or a few slots, so that the motor becomes an m-phase (m≥3) motor ;

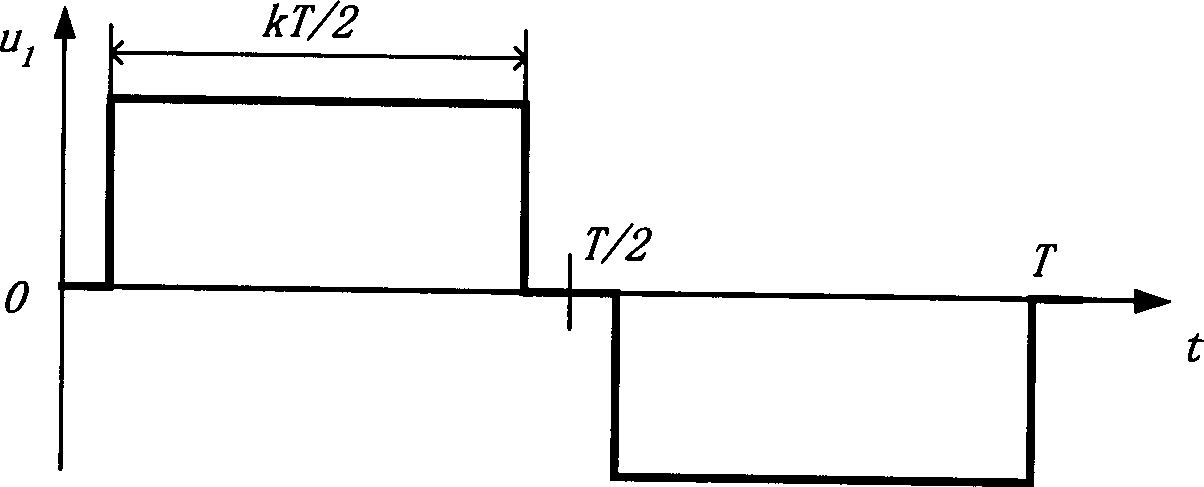

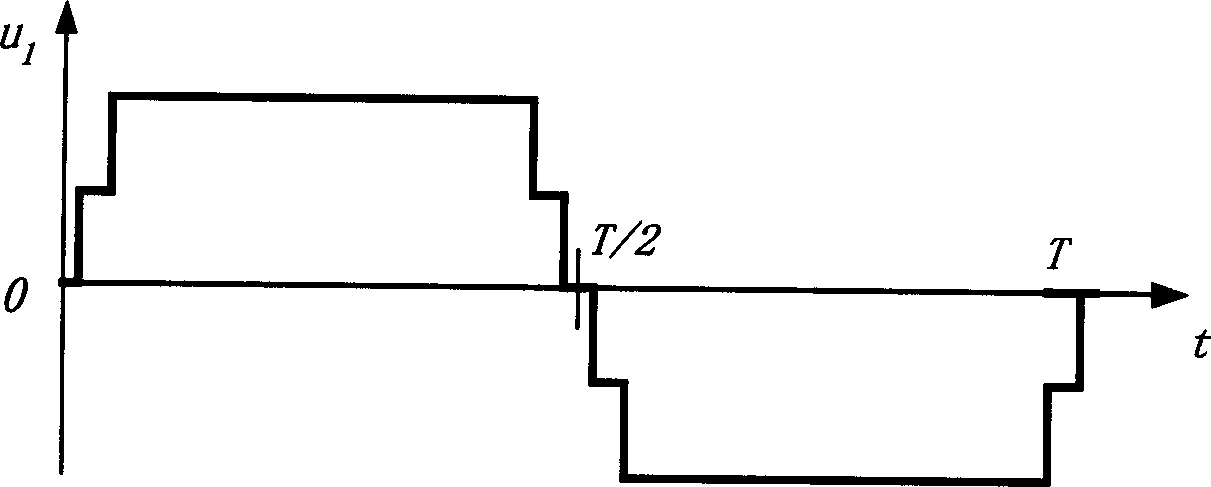

[0018] The voltage applied to the motor in the prior art is generally a sine wave voltage, which is changed to an m-phase (m≥3) quasi-square wave voltage in the present invention. The quasi-square wave voltage mainly refers to the following three voltage waveforms, which are explained with reference to the attached drawings:

[0019] (1) is a short distance square wave voltage, as attached figure 1 shown. where the ordinate u 1 Represents the instantaneous value of a certain phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com