Gusset for a light-weight bag, a bag assembled therefrom, and methods for the manufacture and assembly thereof

A technology for reinforcing plates and bags, applied in the directions of assembly machines, manufacturing tools, metal processing equipment, etc., can solve problems such as increasing manufacturing costs and increasing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] specific implementation

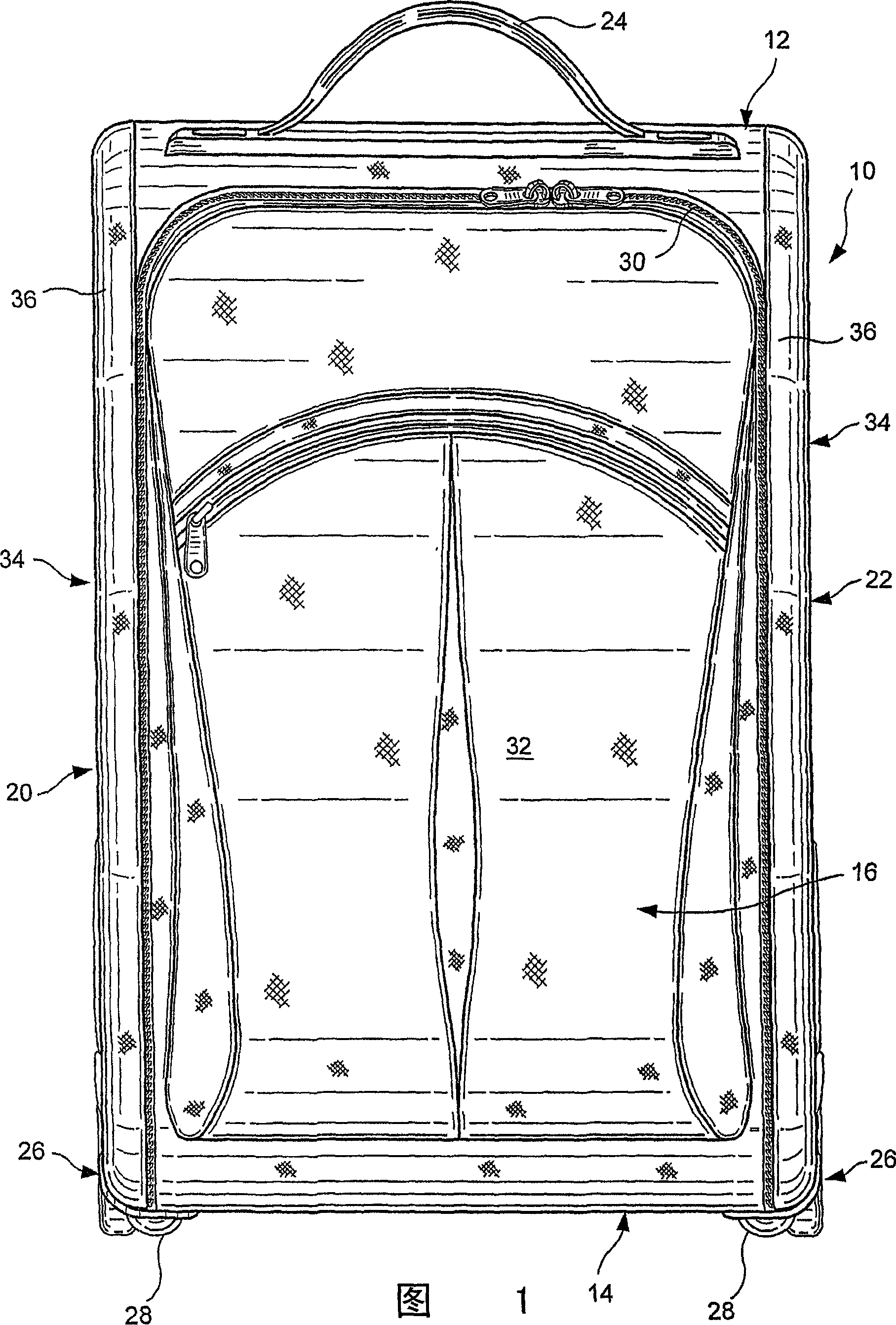

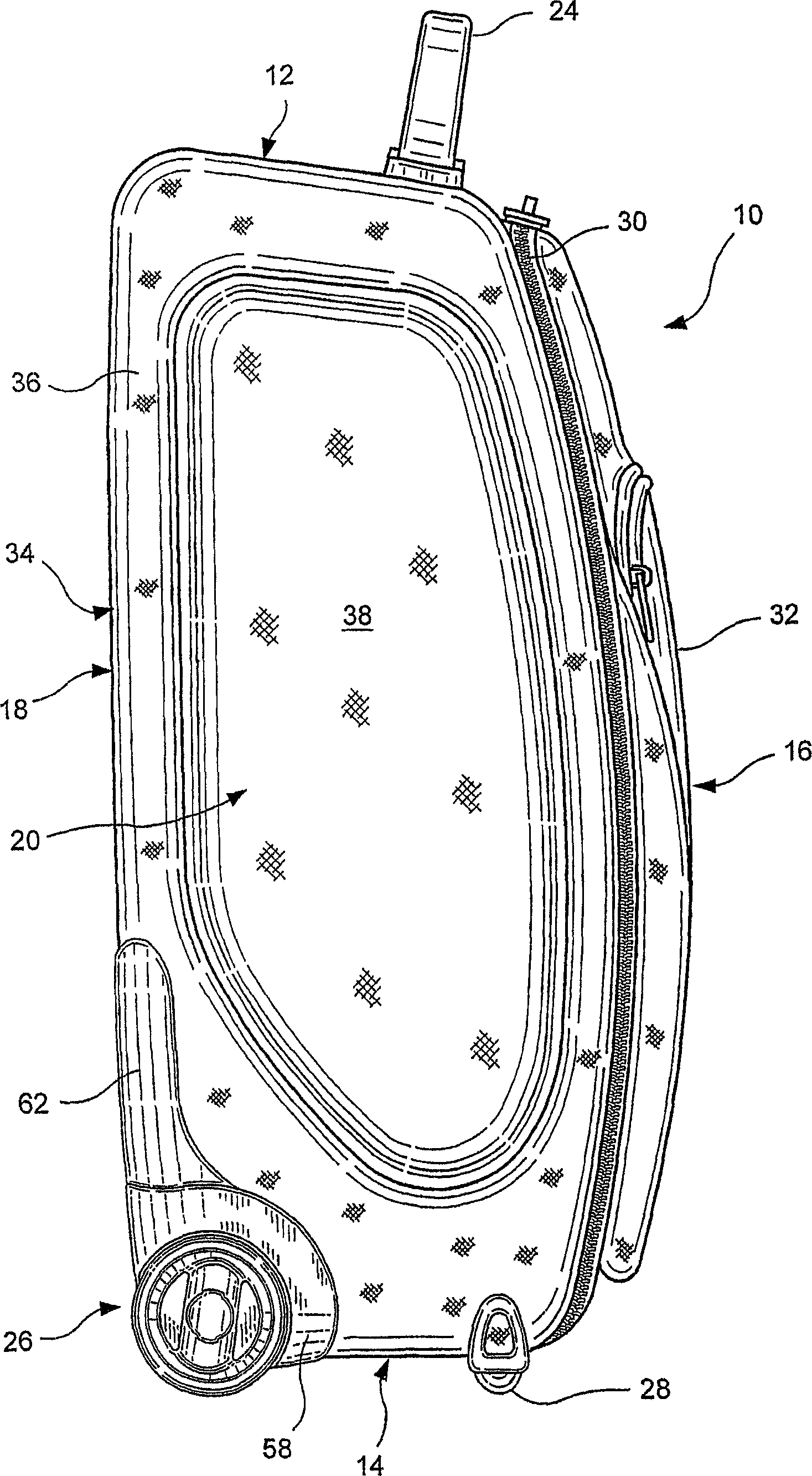

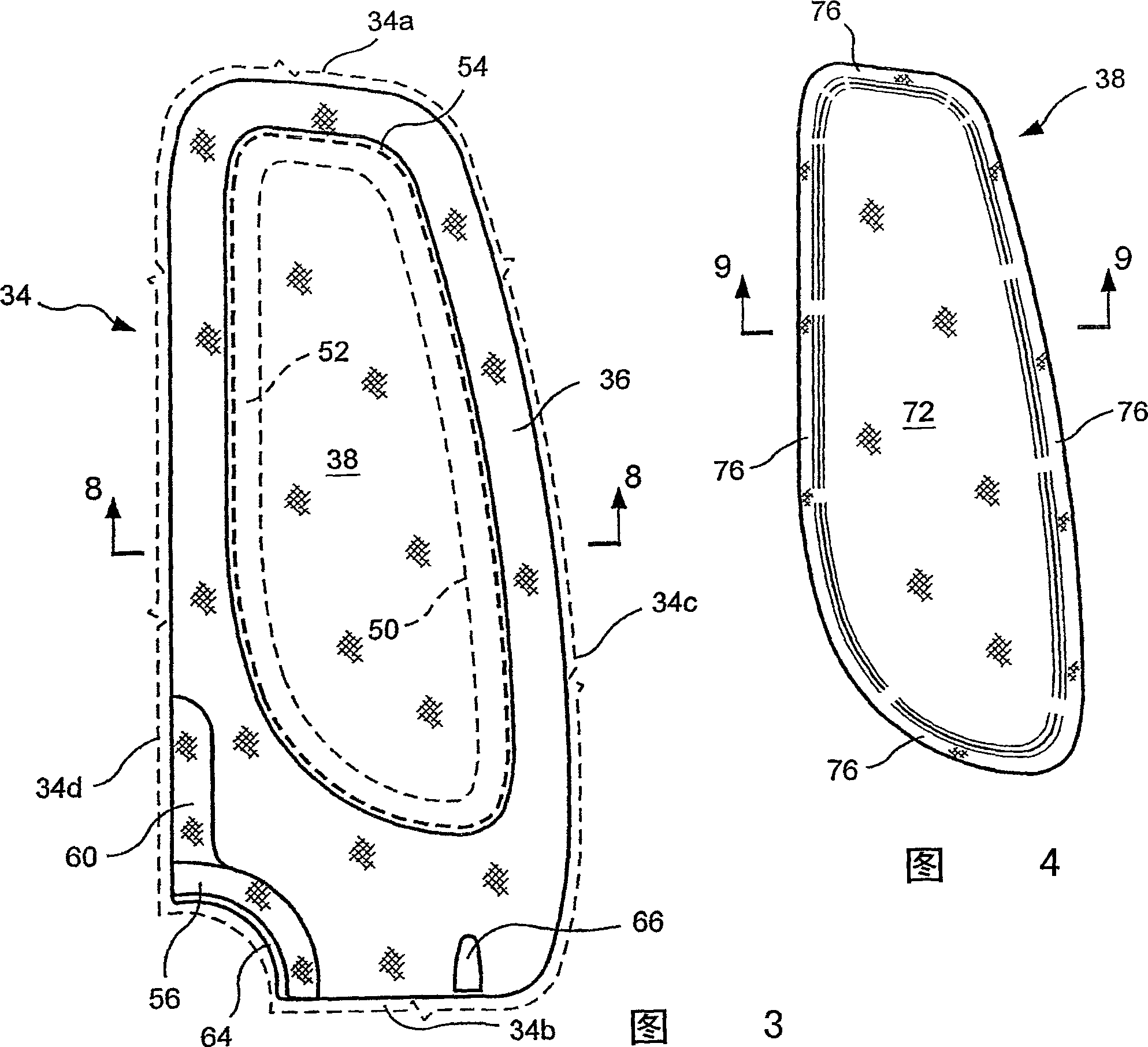

[0051] 1 and 2 illustrate a bag embodiment having a top 12 , a bottom 14 , a front 16 , a back 18 , a left side 20 and a right side 22 . The top, bottom, front and back preferably fit together to form the main body of the bag. At least the front 16 and back 18 of the main body are preferably made of a soft, wear-resistant material such as nylon or a polymer / nylon combination or other high denier fiber content fabric. The top 12 and bottom 14 are also preferably covered by a soft wear resistant material, preferably the same material at the front and rear, but may also include internal or external reinforcement elements, or alternatively may be of a harder higher strength material constitute.

[0052] Carrying handles 24 are attached to the top 12 of the bag, while roller assemblies 26 are mounted at the lower ends of the sides of the bag. If desired, front feet 28 may be mounted near the front on each side to provide support for the bag 10 wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com