Method of mfg. optical component

A manufacturing method and technology of optical components, applied in the fields of optics, photographic plate-making process of patterned surface, optical mechanical equipment, etc., can solve problems such as uneven distribution of light energy and difficulty in correct positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

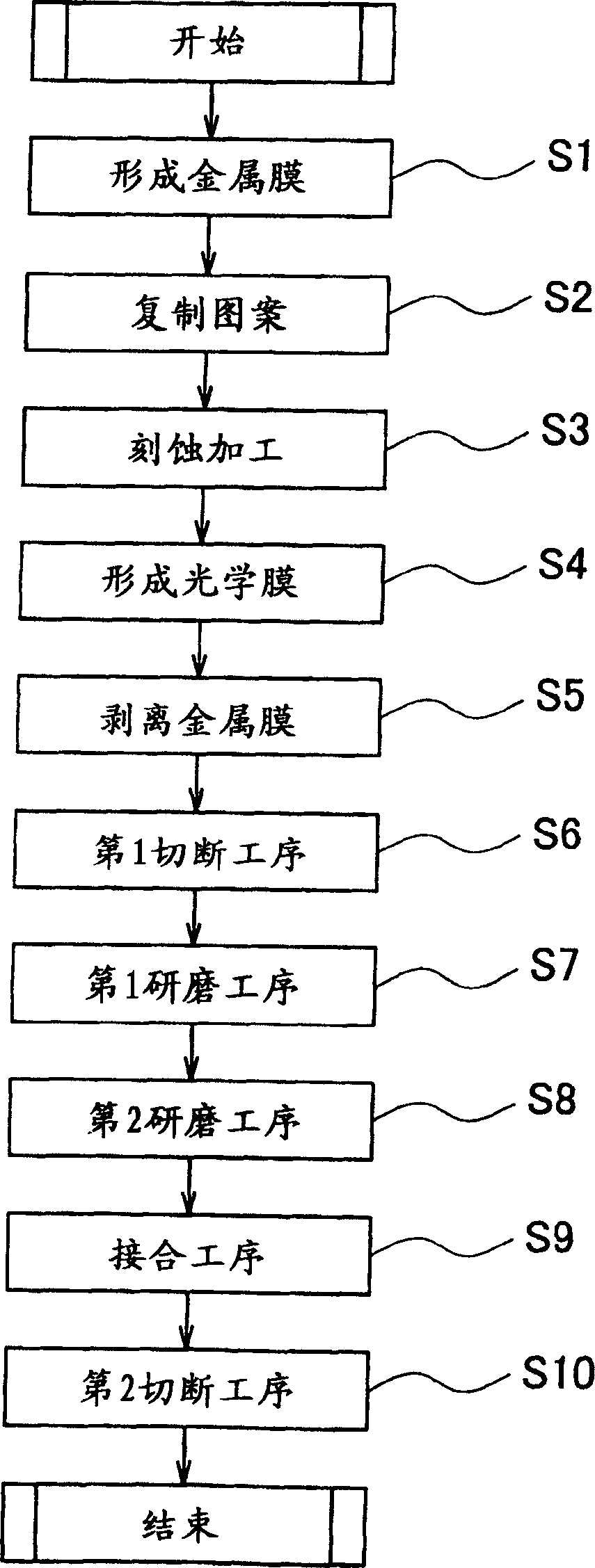

[0022] The following is based on figure 1 The flow chart of the figure illustrates an embodiment of the present invention. First, a large transparent substrate 1 such as a flat glass plate is prepared, and the metal film 9 is uniformly formed thereon (step S1). Here, although a square plate is used as the shape of the transparent substrate 1 for description in this embodiment, the present invention is not limited thereto, and the transparent substrate 1 may be in the shape of a circular plate. In addition, at this time, the surface of the large transparent substrate 1 on which the metal film 9 is formed is previously polished.

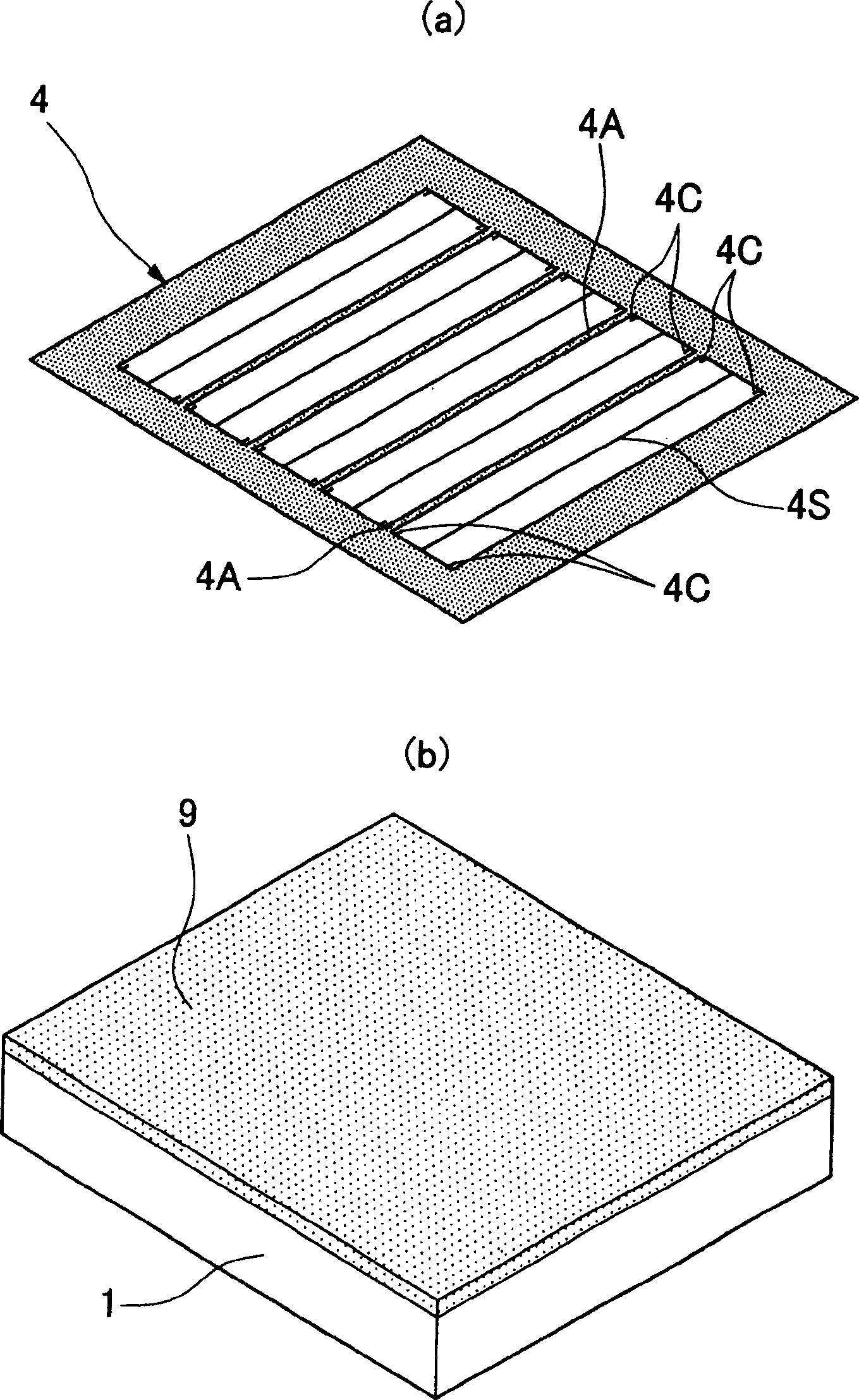

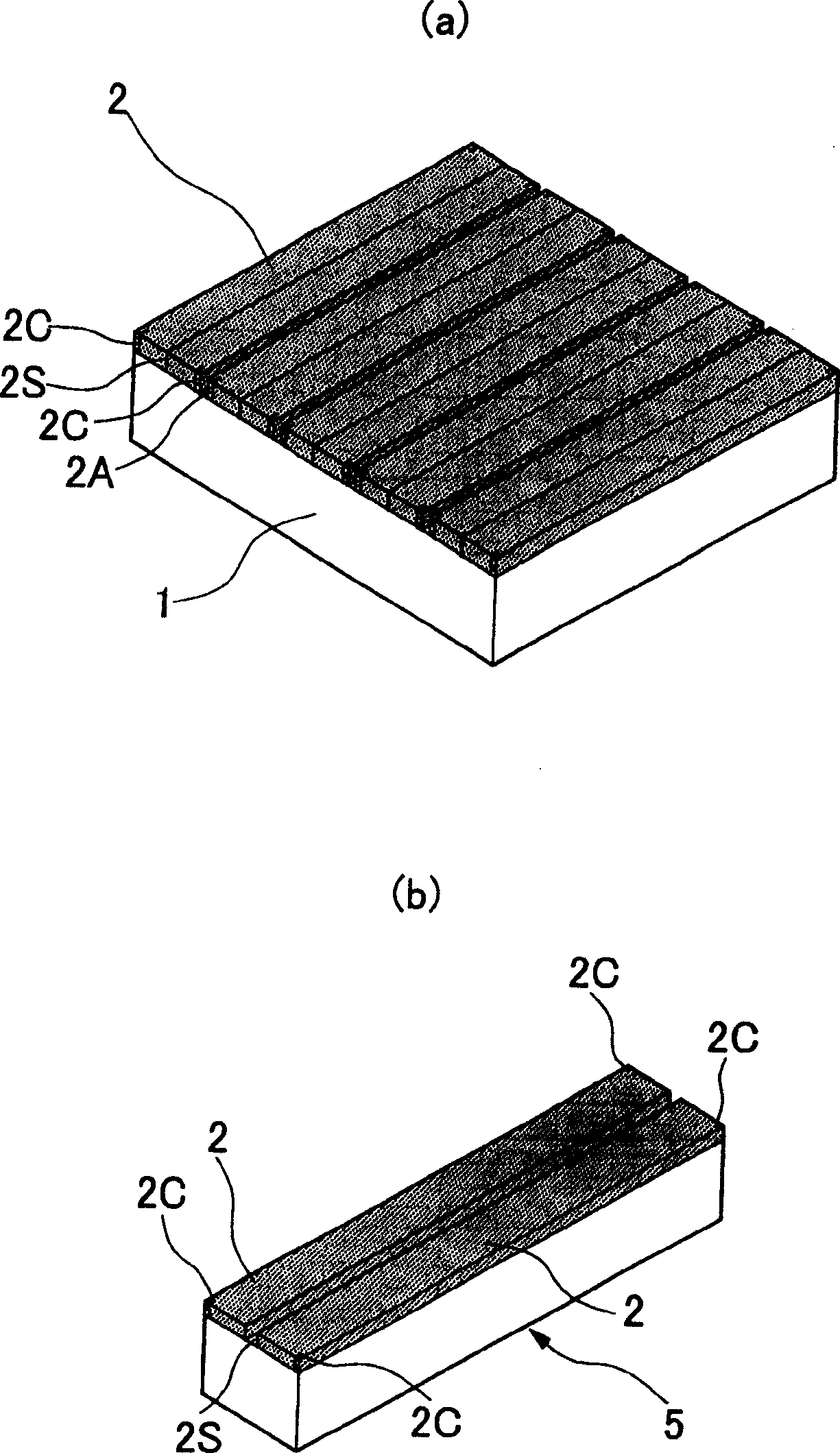

[0023] Then, like figure 2 As shown in (b), the flat plate-shaped large transparent substrate 1 formed with the metal film 9 is kept in a stable state, and a photosensitive agent such as a photoresist is coated on the surface, and used figure 2 The mask member 4 shown in (a) forms an exposure pattern by exposing the punched part of the mask membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com