Liquid crystal display device and manufacturing method of the same

一种液晶显示、设备的技术,应用在晶体管、静态指示器、仪器等方向,能够解决布线高度差、向错等问题,达到降低侧面高度差、降低电阻、粘附性改善的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

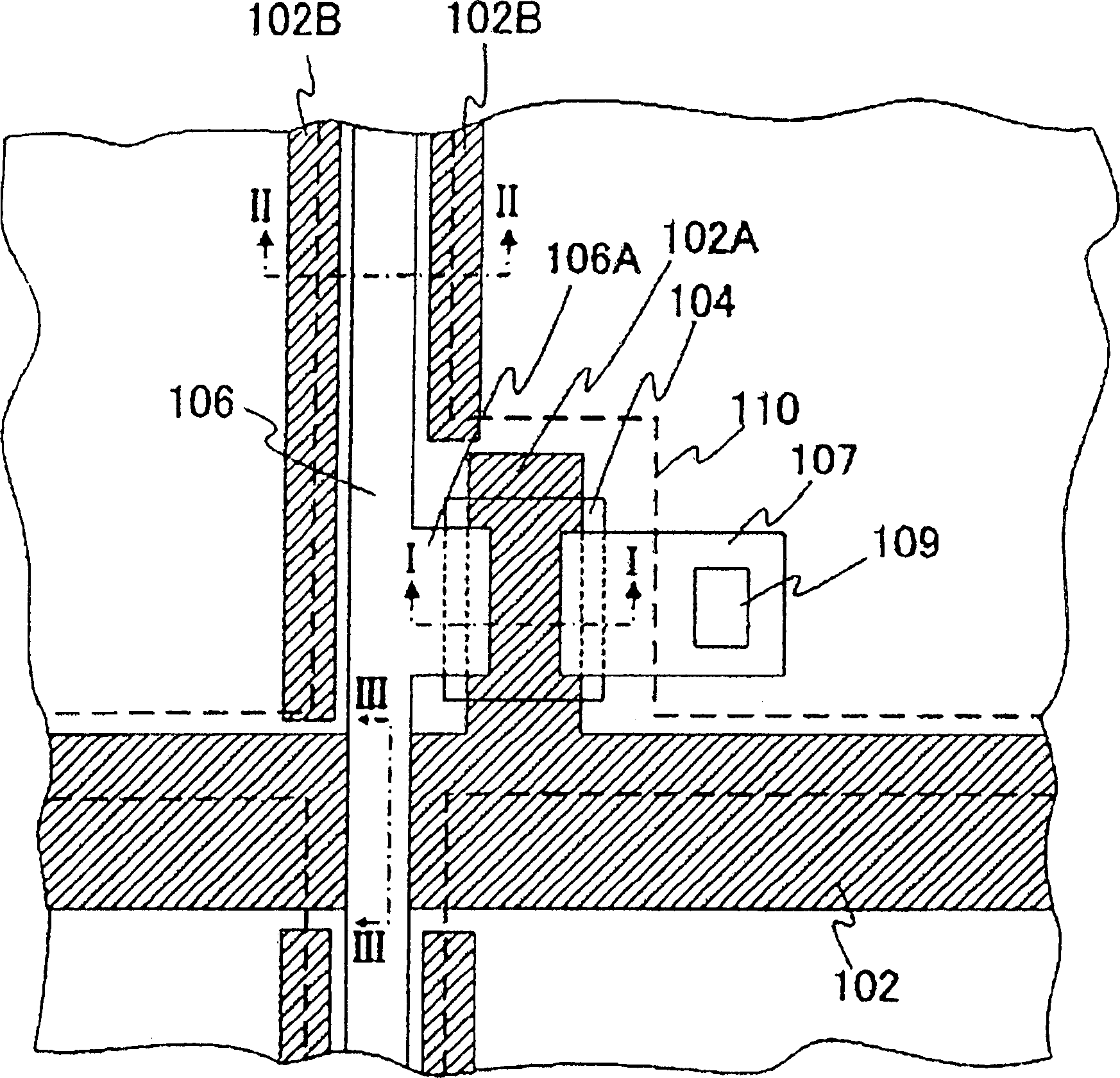

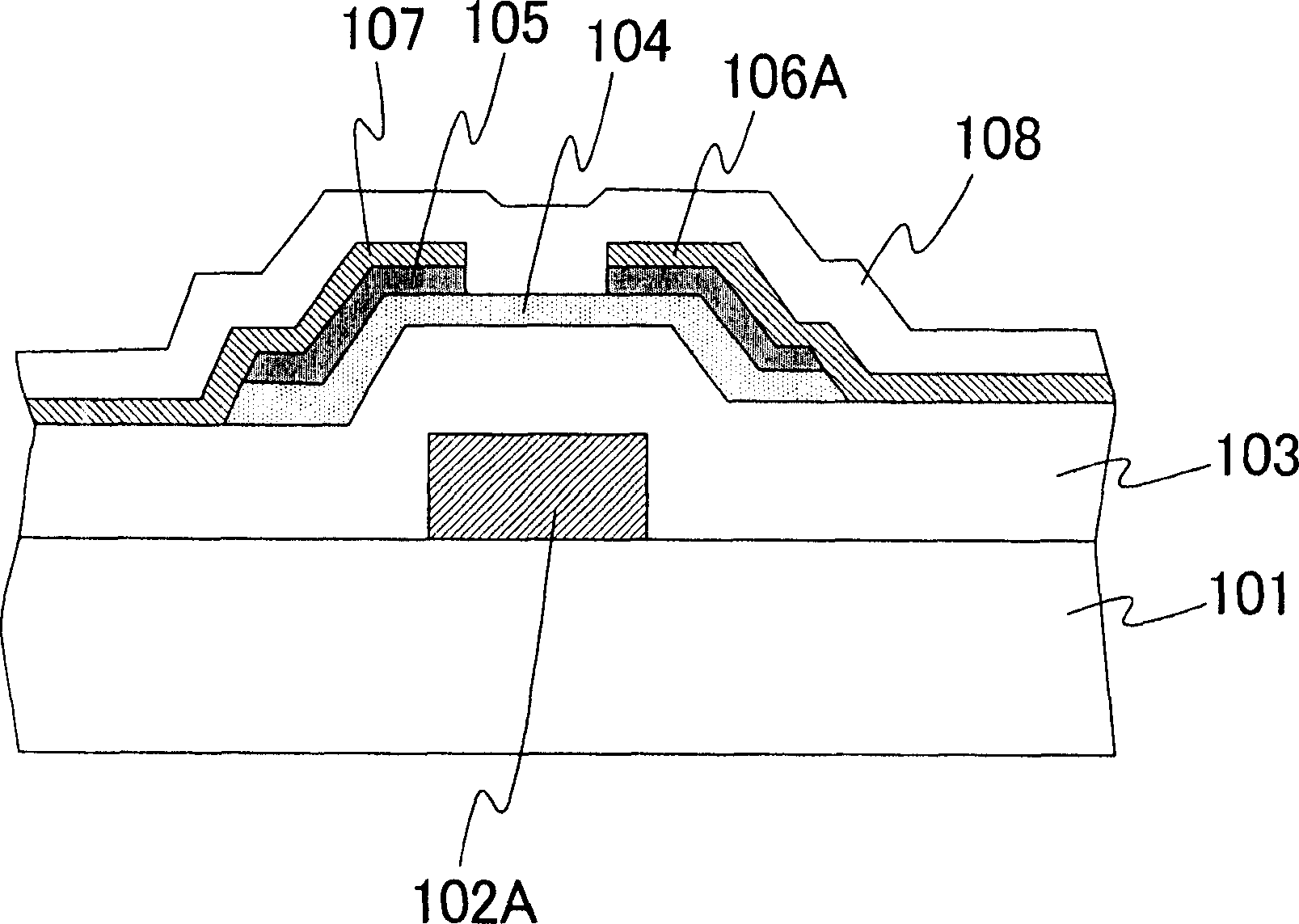

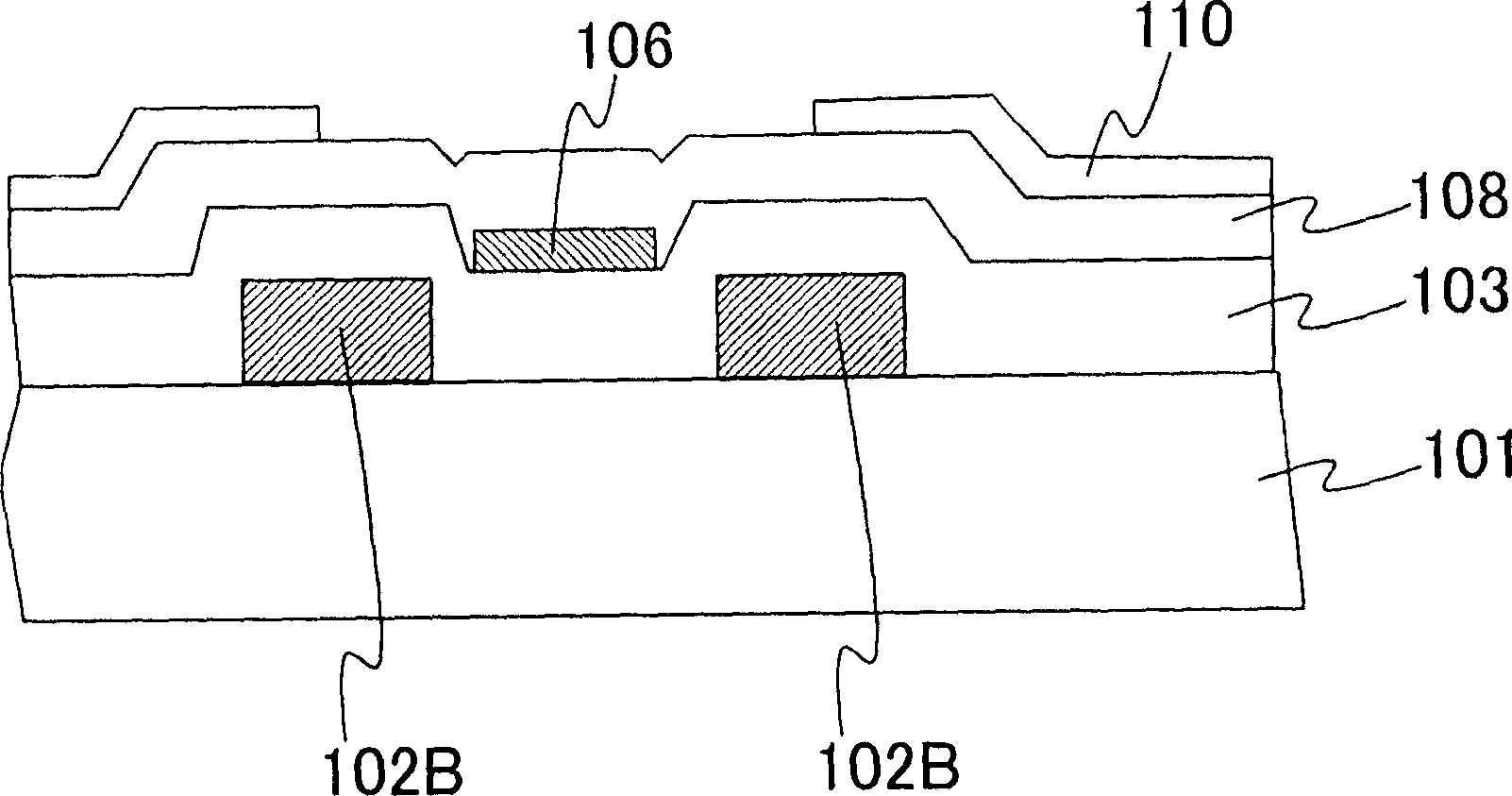

[0024] Embodiments of the LCD device of the present invention will be described with reference to the accompanying drawings. image 3 with Figures 4A to 4C The structure of a TFT substrate as an example of the first substrate for display of the LCD device of the present invention is shown. A gate wiring 2 is formed in a groove on the surface of an insulating substrate 1 made of a glass substrate or a plastic substrate. Incidentally, polycarbonate, polyether sulfone, polyarylate, or the like can be used as the plastic substrate. Drain wiring 6 is formed on insulating substrate 1 so as to be perpendicular to gate wiring 2 . TFTs as switching elements are arranged near the crossing portion between the gate wiring 2 and the drain wiring 6 . The TFT has a gate electrode 2A formed in a trench 12 at the surface of an insulating substrate 1 and a gate insulating film 3 formed on the insulating substrate 1 including the gate electrode 2A, as Figure 4A shown. Gate insulating film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com