Grouted screw pile ,construction method therefor and grouting arrangement employing same

A construction method and technology of grouting device, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as limitation of drilling resistance, extension of construction period, straight line section, waste of materials, etc., to improve operating efficiency, Drilling resistance is small, the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

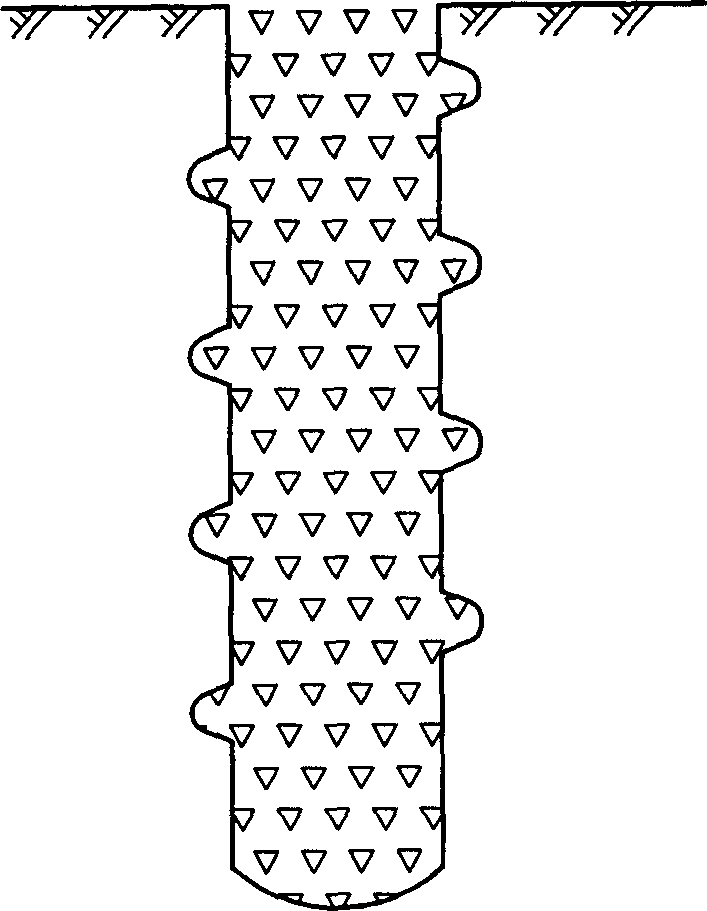

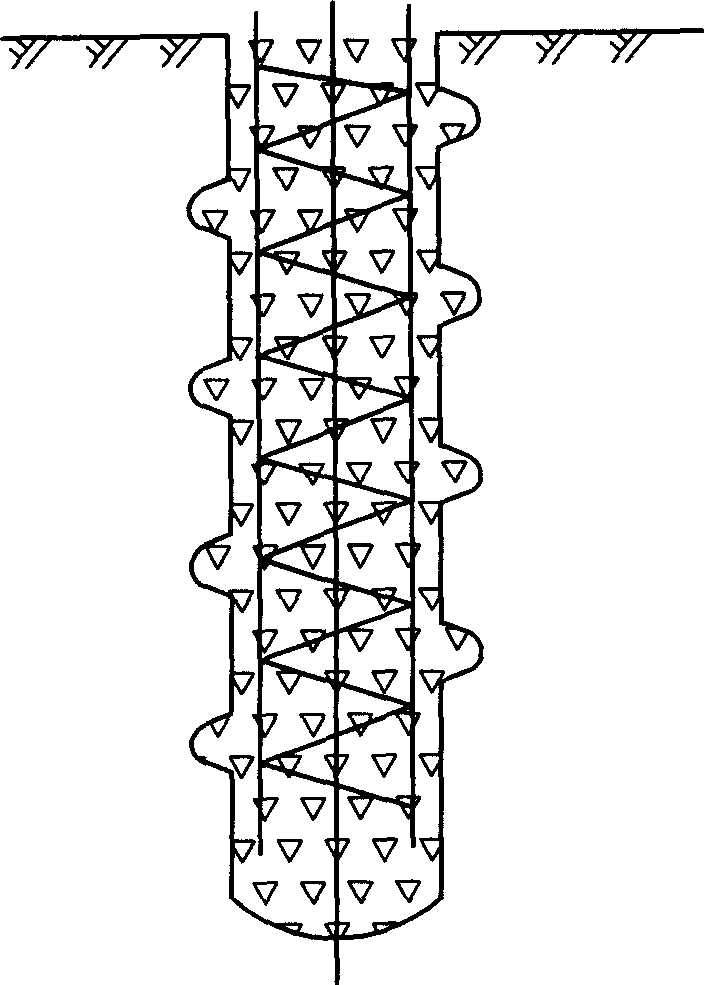

[0034] The grouting threaded pile comprises: a concrete pile body 7, the concrete pile body contains a reinforcement member 8, and the outer surface of the concrete pile body has a spiral protrusion 9.

Embodiment 2

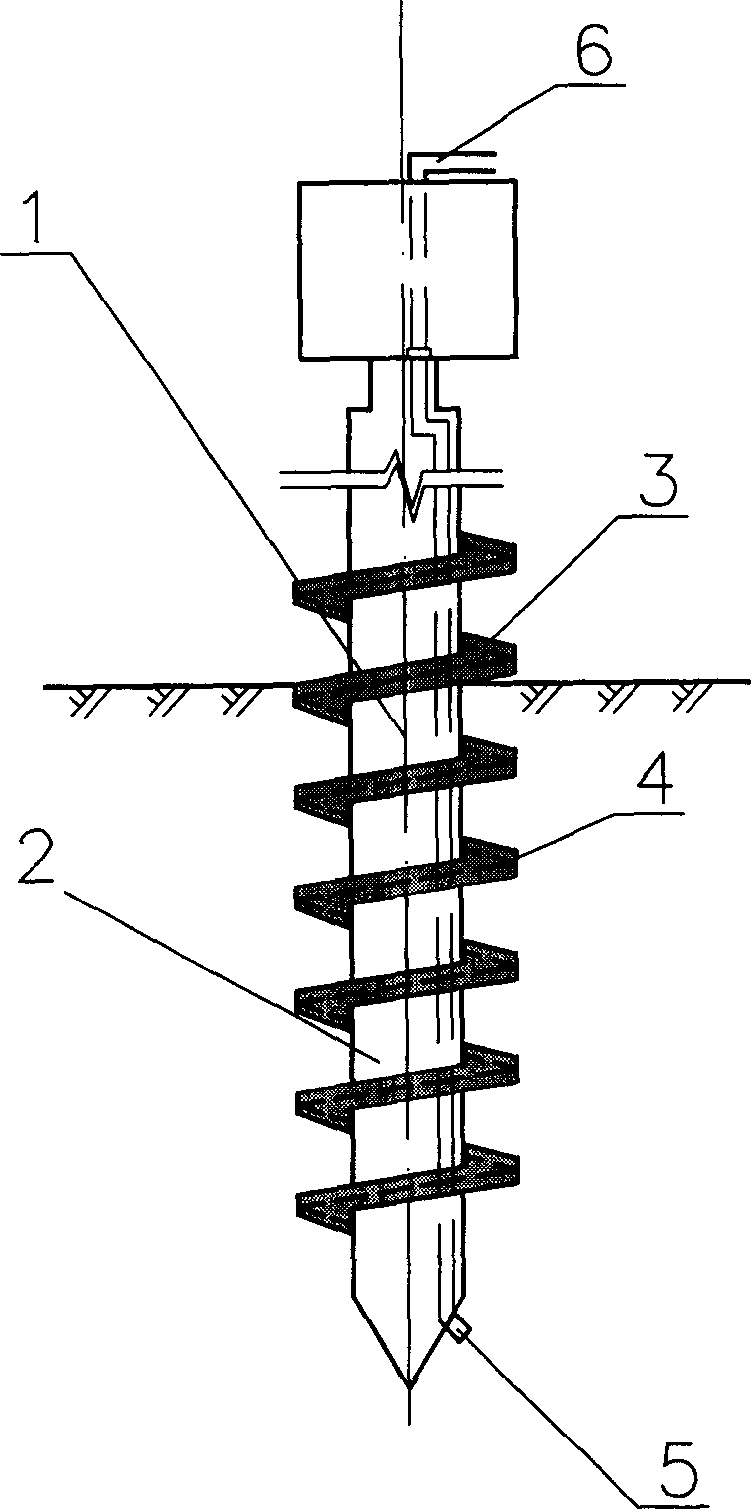

[0036] Grouting device 1, described grouting device 1 has drill pipe 2, and described drill pipe 2 has thread 3 outside, and described thread 3 has hollow grouting channel 4, and described hollow grouting channel 4 reaches As for the drill bit, the drill pipe 2 has a concrete pipeline 6 inside, and the end of the concrete pipeline has a grouting port 5 .

Embodiment 3

[0038] In the above-mentioned grouting screw pile construction method, prefabricated cement slurry, concrete, and steel cage should be prepared before grouting and drilling, the drilling rig is spud drilling, the grouting device is pressurized according to the design speed, and the drill bit is drilled into the soil while passing through the grouting pile. The cement slurry is injected from the slurry channel to the grouting port, and the concrete is also injected along the outer wall of the thread. When the drill reaches the design depth, stop injecting the cement slurry, and then reverse the grouting device at the same speed, lift it to the design pile top, and finally Place the reinforcement cage, and the thread trajectory should be consistent when drilling and lifting.

[0039] Example 3:

[0040] The above-mentioned grouting threaded pile construction method, when the grouting threaded pile is used for the foundation, the prefabricated cement slurry and concrete should be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com