Planetary electromagnet chopped mode stepless speed changer

A continuously variable transmission, chopper technology, applied in transmission parts, gear transmissions, belts/chains/gears, etc., can solve the problems of high material requirements, complex structure of the continuously variable transmission, and strict requirements for speed regulation and speed regulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

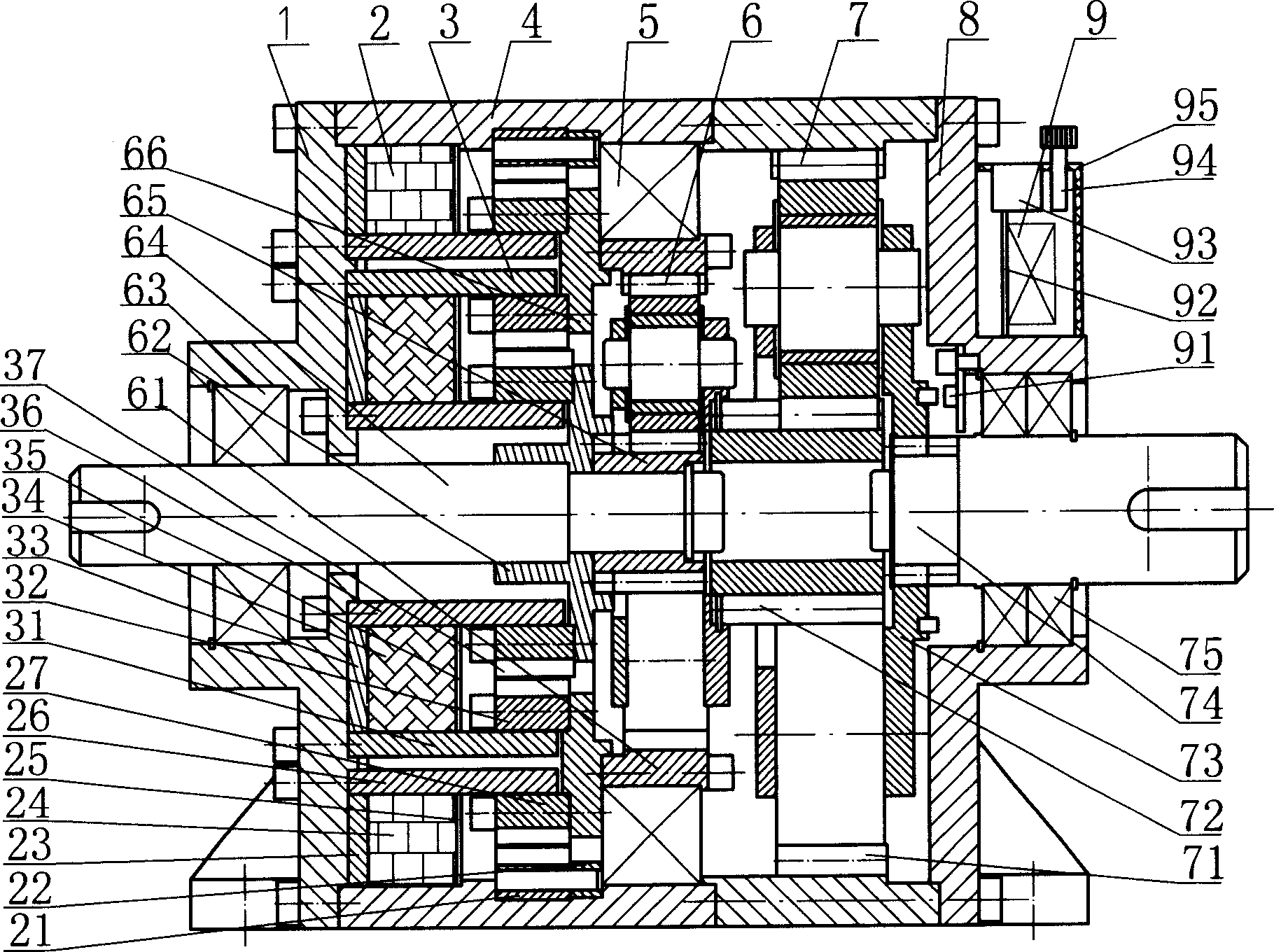

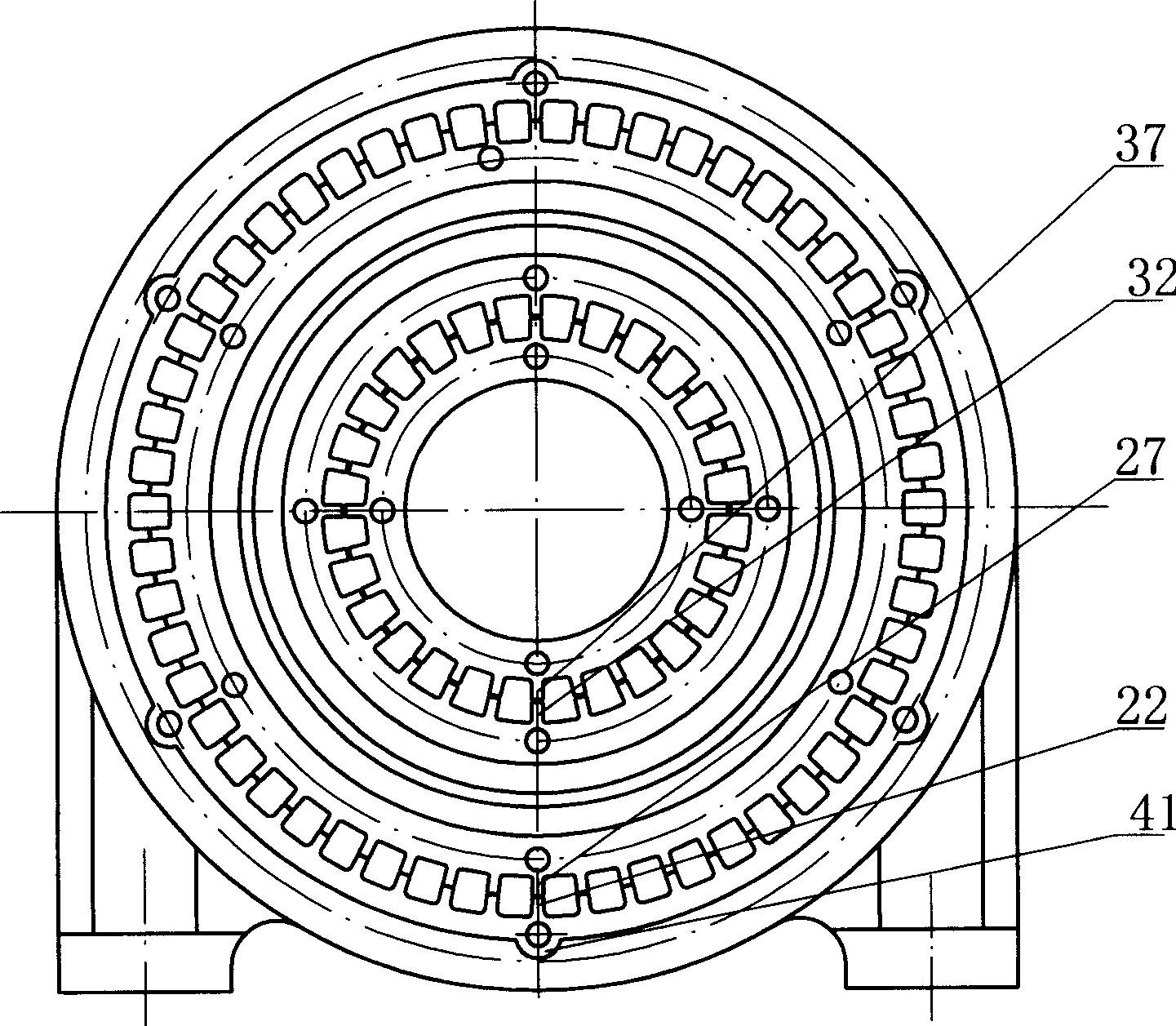

[0012] Planetary electromagnetic chopper type continuously variable transmission of the present invention, as figure 1 As shown, the electromagnetic brake 2 is composed of a front end cover 1, a casing 4, a brake fixed tooth 21, a brake bottom ring 23, a brake coil 24, a brake cover ring 25, a brake inner ring 26, a brake movable tooth 27, and a speed regulating inner ring gear 61 , inner ring gear and tooth plate 66, the brake fixed teeth 21 are fixed through the recess 41 of the casing, the casing 4 and the front end cover 1, and the brake fixed teeth sleeve 22 restricts the position of the brake fixed teeth 21 through the ring gear bearing 5 The brake movable tooth 27 is connected with the speed-regulating inner ring gear 61 through the inner ring gear connecting tooth plate 66, and can rotate around the brake inner ring 26. The brake cover ring 25 seals the brake coil 24 to the casing 4 and the brake bottom ring 23 , In the space of the brake inner ring 26 to protect the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com