Air vent apparatus for water tube

A technology for exhaust devices and water pipes, applied in the direction of pipe elements, piping systems, transportation and packaging, etc., which can solve the problems of increased flow rate, peeling of lining, increased pressure loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

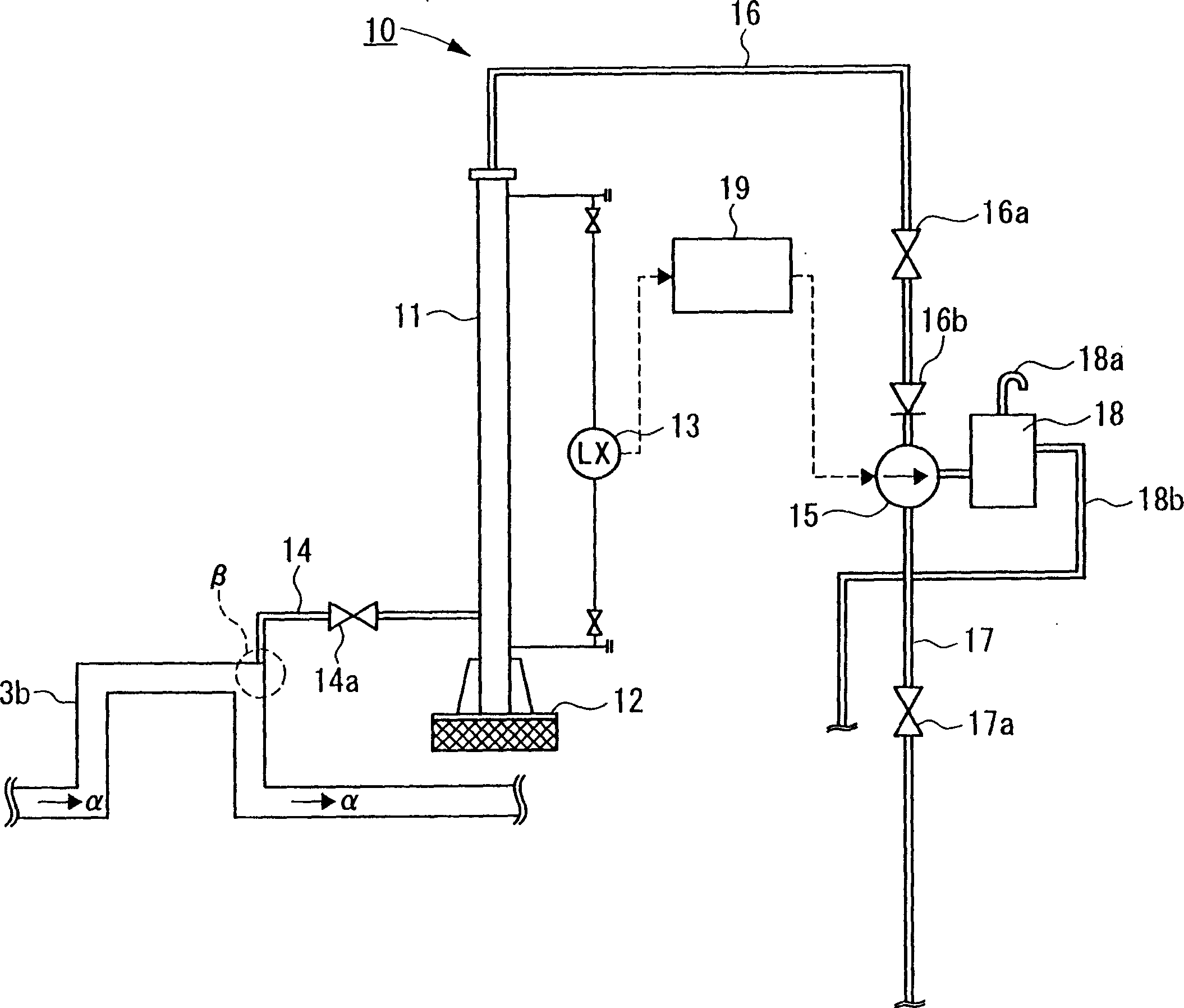

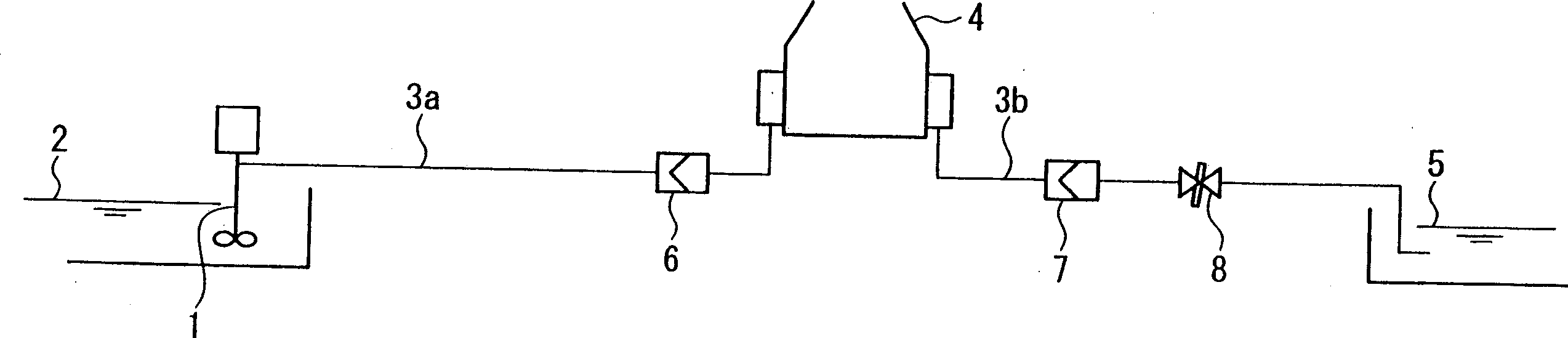

[0041] figure 1 The exhaust device 10 according to the embodiment of the present invention will be described. The air separator pipe 11 of the exhaust device 10 is installed on the ground 12 so as to have an axial direction in a vertical direction. In this embodiment, the length of the air separator pipe 11 is 6 m. The air separator pipe 11 is equipped with a water level detector 13 for detecting the water level of seawater which has flowed into the air separator pipe 11 .

[0042] The lower part of the air separator pipe 11 is connected to the circulating water pipe 3b on the water release side through the connecting pipe 14 . More specifically, the connecting pipe 14 is connected to a portion of the circulating water pipe where the air tank is prone to occur.

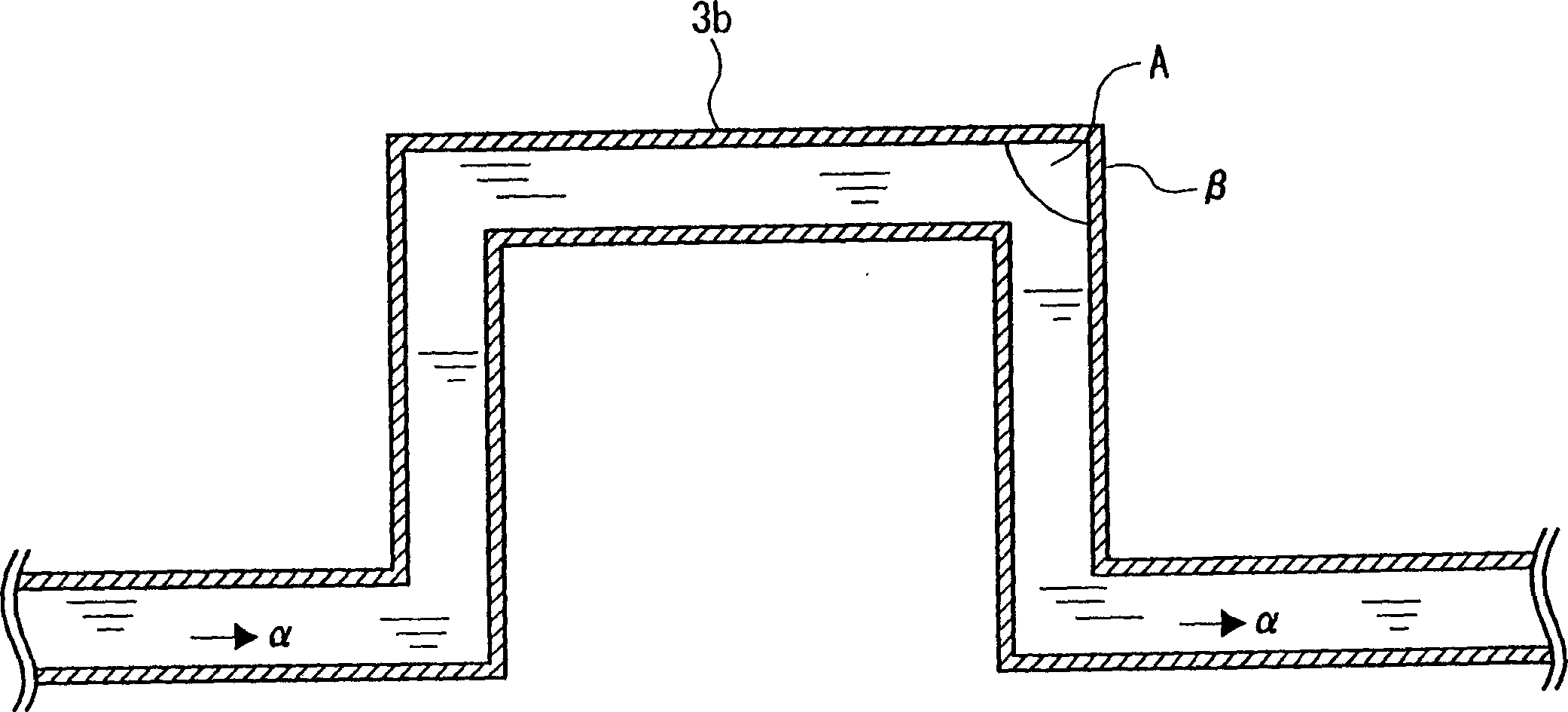

[0043] For example, if the height at which the circulating water pipe 3b is placed is raised along the flow direction of the water and then lowered, (for example, figure 1 α direction), then the air groove is ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com