Method and device for inspecting a wafer

A measurement device and wafer technology, which is applied in the field of macroscopic defect detection, can solve the problems of inability to adjust, expensive image measurement and image processing, etc., and achieves the effect of reliable identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The same reference symbols in the various figures denote identical - or substantially identical - acting elements or groups of elements.

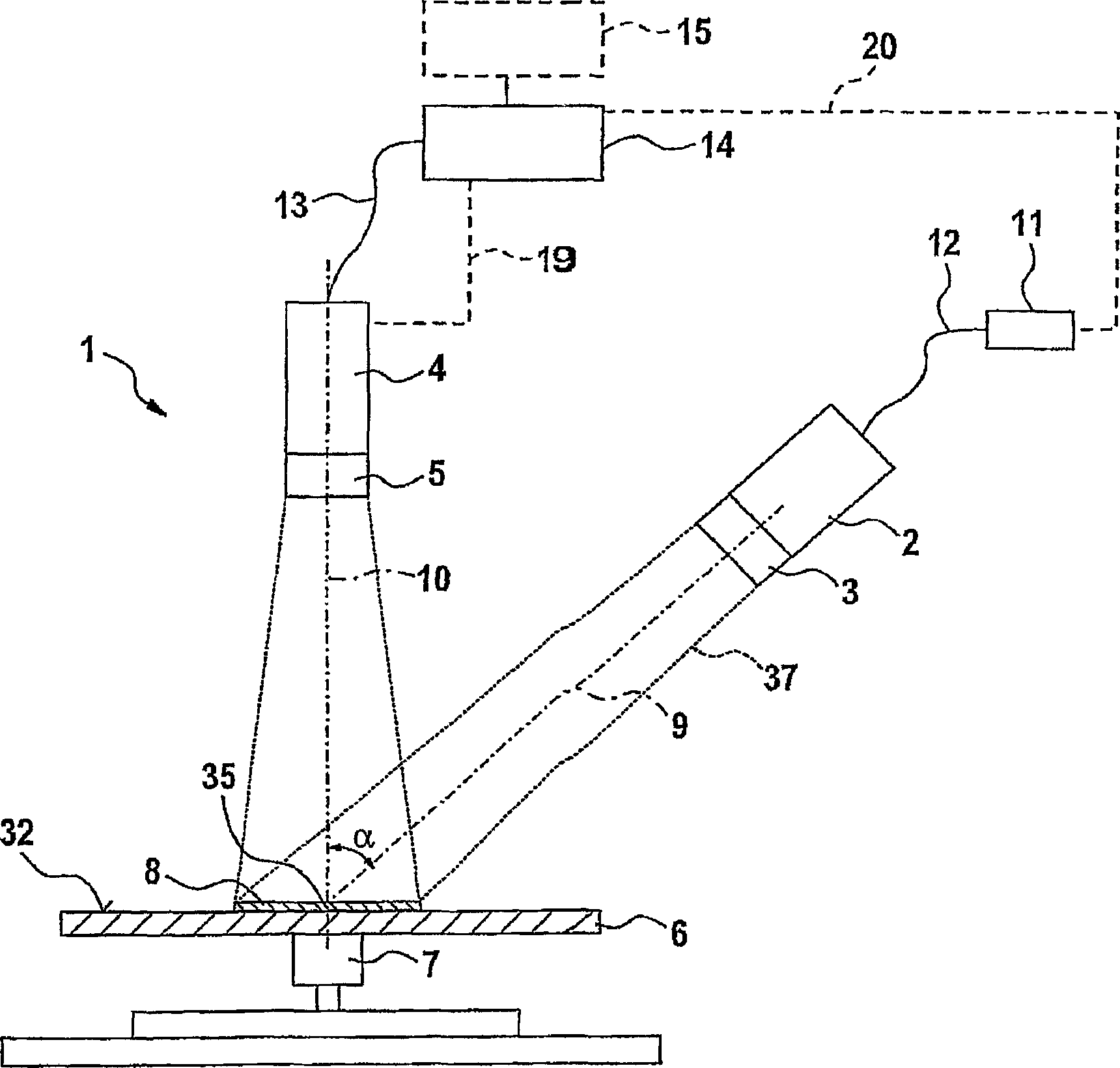

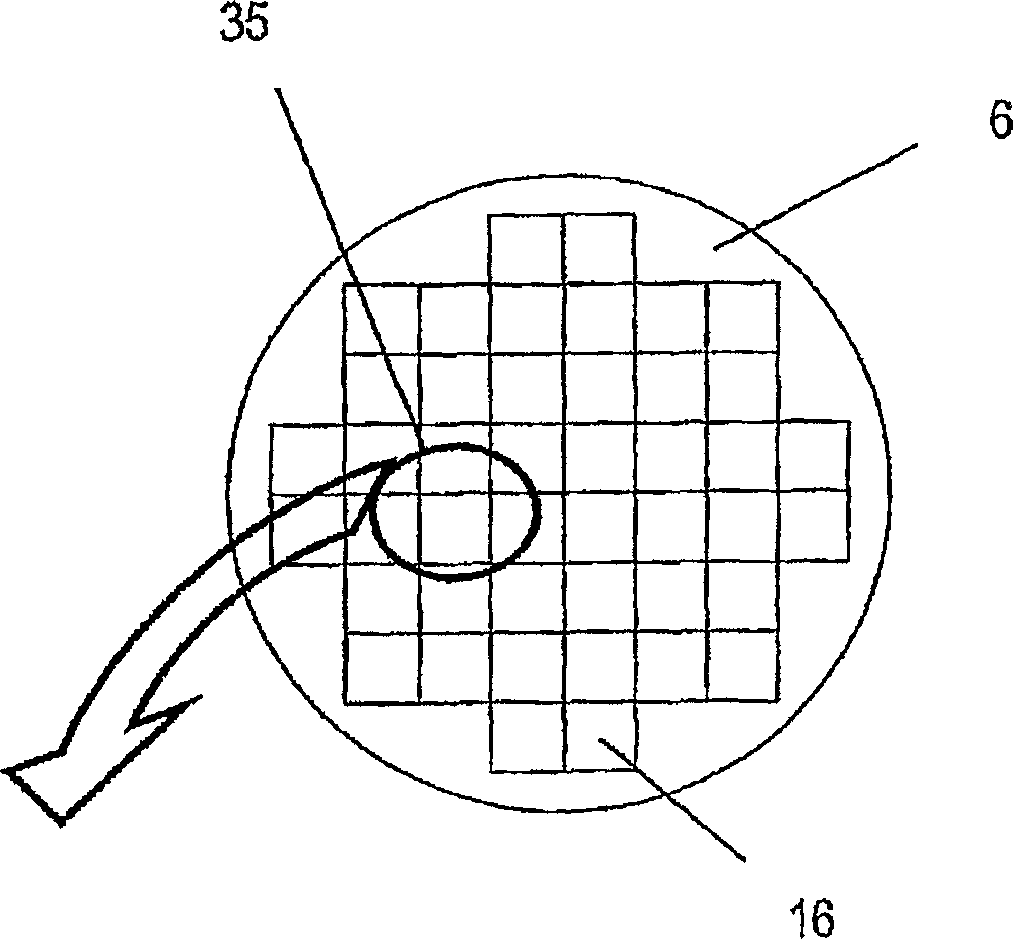

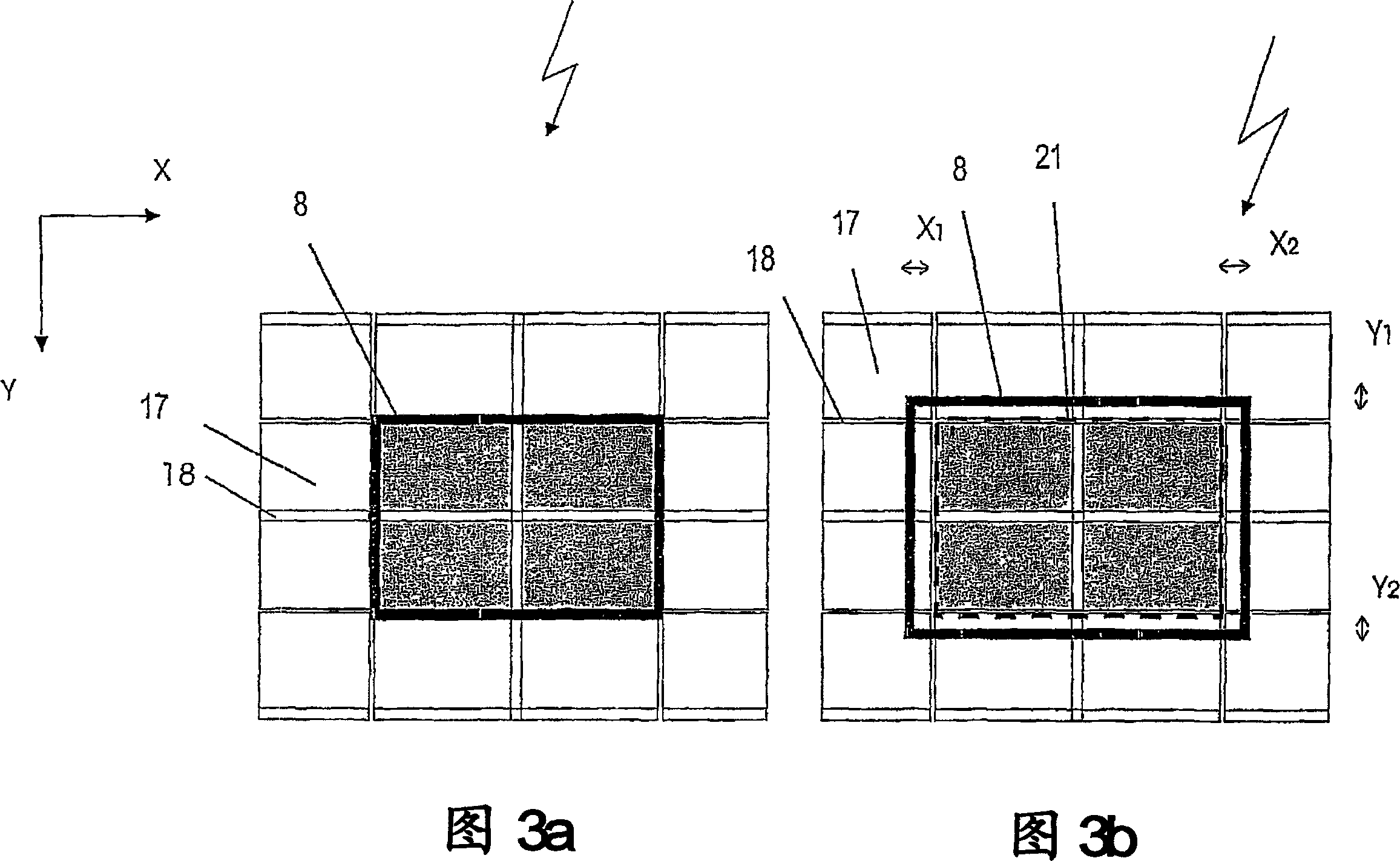

[0044] Such as figure 1 As shown, in the wafer detection device 1, when compared with the prior art, the present invention adopts the following preventive measures: the image measurement device 4 (for example, a column camera or a matrix camera, preferably a CCD- camera) comprising a zoom objective 5 whose focal length can be varied manually or electronically, while the surface 32 of the wafer 6 is continuously imaged in a significant manner in the image measuring device 4 . Alternatively, the distance between the image measuring device 4 and the surface 32 of the wafer 6 can be varied, for example by moving the image measuring device 4 along the imaging axis 10 manually or by an electric motor. After a change in the image distance, this objective 5 has to be precisely readjusted. Another way is to also make the distance between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com