Multi-spot combustion engine

An engine and multi-point technology, applied in the direction of engine components, engine ignition, combustion engine, etc., can solve the problem of large room for improvement of the engine, and achieve the effects of increasing flame diffusion speed, improving fuel consumption, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

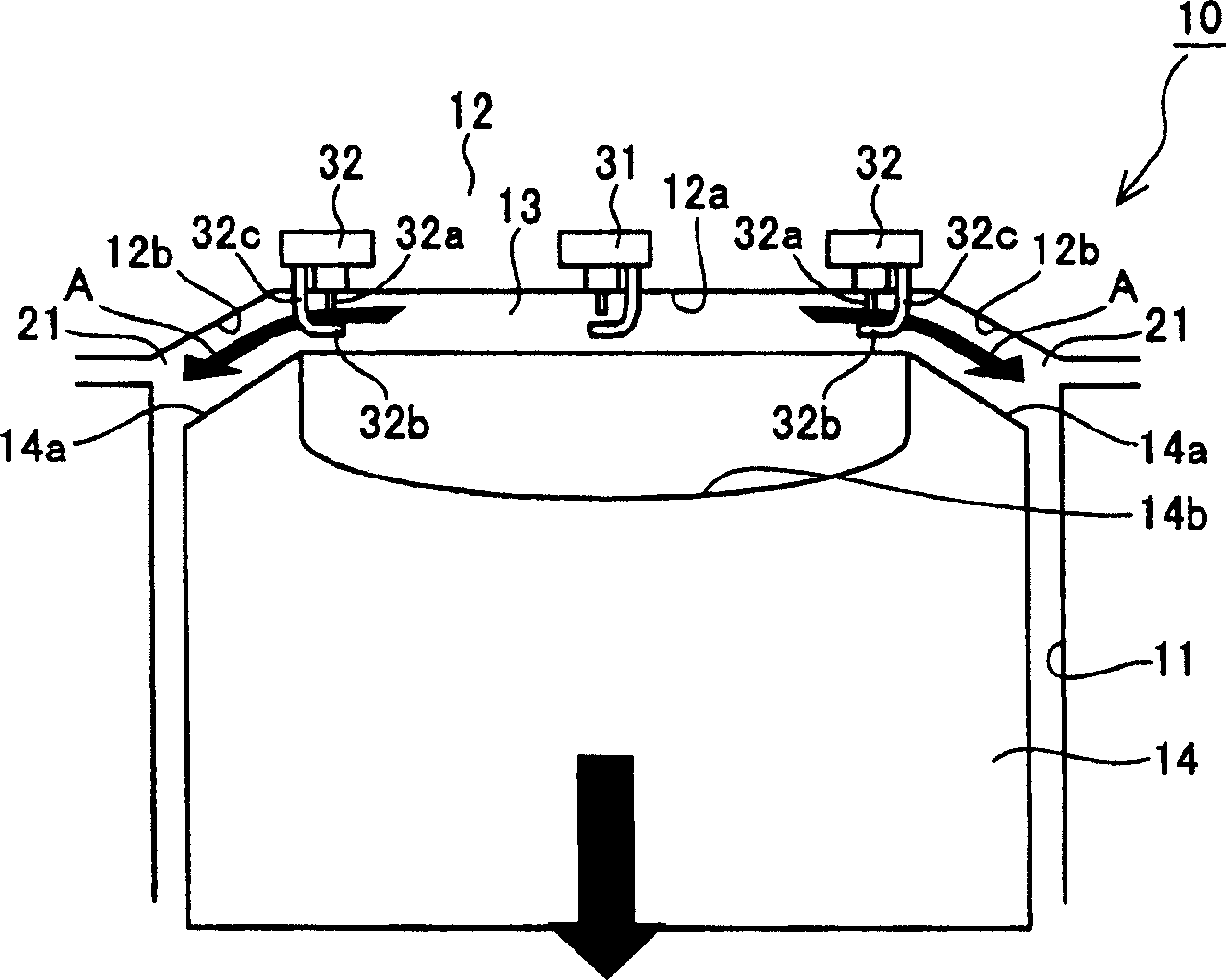

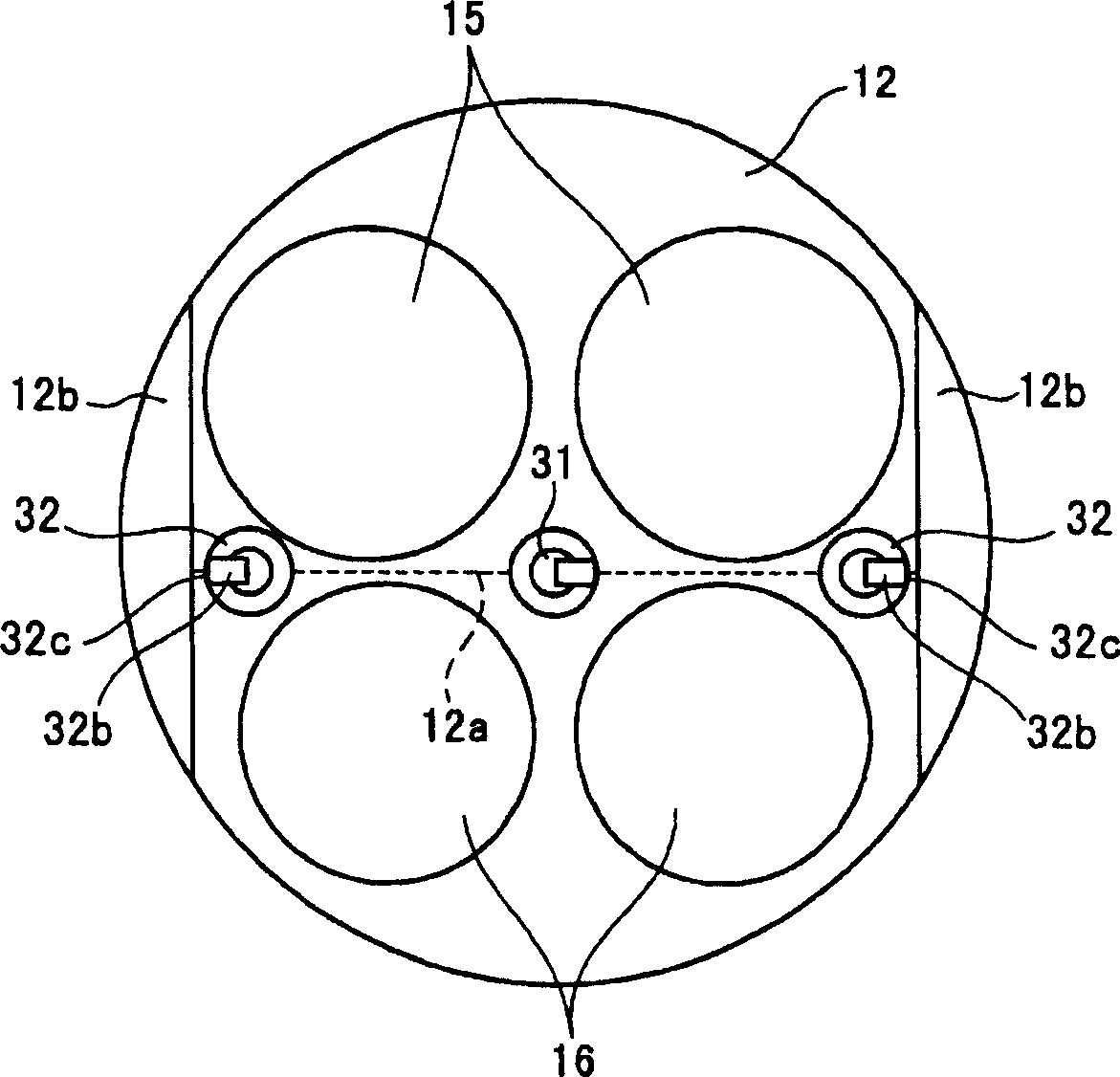

[0020] Figure 1A and 1B The peripheral spark plug arrangement structure of the multi-point ignition engine according to the first embodiment is shown, wherein, Figure 1A is a side elevation view, and Figure 1B is shown in Figure 1A Plan view of the cylinder head in .

[0021] shown in Figures 1A to 1B The multi-point ignition engine 10 in the FIG. 1 includes a combustion chamber 13 , which is constituted by a cylinder block 11 and a cylinder head 12 . The combustion chamber 13 is a ridge-roof type of combustion chamber and is as Figure 1B As shown, the intake valve 15 is provided on one side and the exhaust valve 16 is provided on the other side across the roof ridge line 12a. In addition, the center spark plug 31 and the peripheral spark plug 32 are arranged along the roof ridge line 12a.

[0022] An inclined crown surface 14a that becomes more convex at the center portion of the combustion chamber 13 is formed on the periphery of the crown surface of the piston 14 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap