A curtain type membrane assembly

A curtain membrane and module technology, applied in the direction of sustainable biological treatment, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve problems such as difficult sludge cleaning, membrane surface pollution, and affecting water effluent effect. To achieve the effect of cleaning the membrane silk easily, not easy to pollute, and improving the water outlet efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

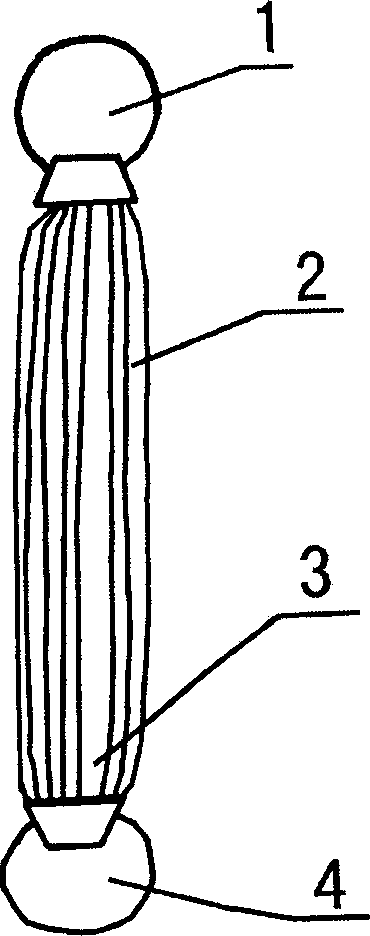

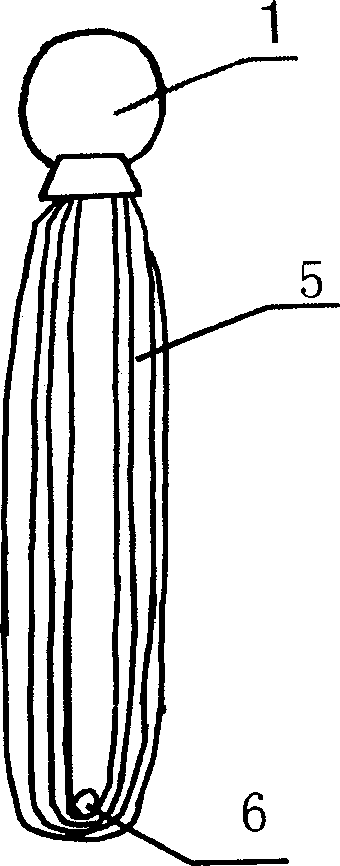

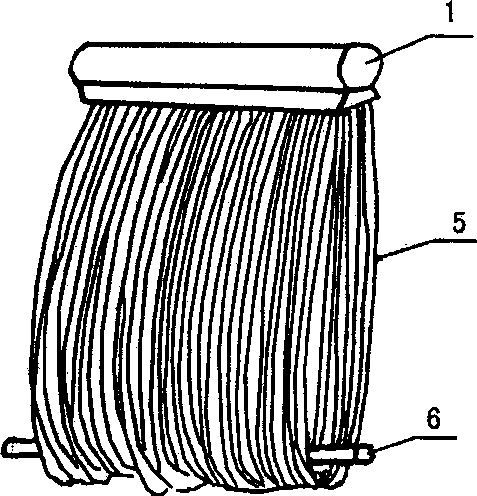

[0015] The present invention adopts the hollow fiber microporous membrane 5 in the form of "U", the opening end of which is bonded to the upper collecting pipe 1, and the lower end is not connected to the collecting pipe. Install a perforated tube thinner than the upper collecting tube in the U-shaped gap, as the lower insertion tube 6, the insertion tube 6 is connected with the aeration tube 8, and the aperture and number of holes of the insertion tube 6 are less than the aeration tube 8 pore diameter and number of holes, and the openings are facing upwards, the released air bubbles blow directly into the voids of the hollow fibers. Because this air blowing pipe is not directly connected with silk, it can be pulled down, so the lower end of U-shaped wire 5 is a free end, and the activated sludge hanging on can be blown or rinsed off easily. Because this little insertion pipe 6 passes through the lower space of this row of U-shaped silk membranes, it also plays a role in posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com