Method for electroplating aluminium alloy products

An aluminum alloy product and pre-nickel-plating technology, applied in the field of electroplating, can solve the problems of high cost of raw materials and processing, long total time of electroplating process, high cost of stripping and repairing, etc. The effect of reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

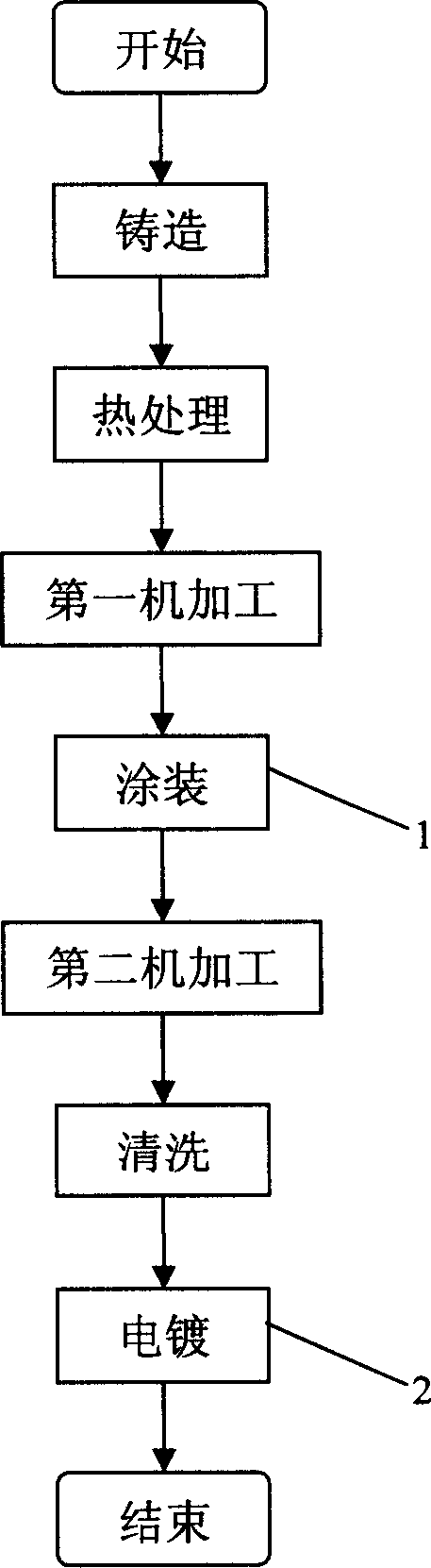

[0025] Such as figure 1 Shown is the flow chart of the electroplating method for aluminum alloy products of the present invention; the present invention improves the traditional process of electroplating first and then painting to first painting and then electroplating, and has achieved good results. After conventional casting, heat treatment, and first machining of aluminum alloy wheels, the first process of coating is directly carried out. After completion, the product is subjected to second machining and then cleaned to ensure that it can conduct electricity during electroplating, and then enters the second process of electroplating to complete the entire process. electroplating process.

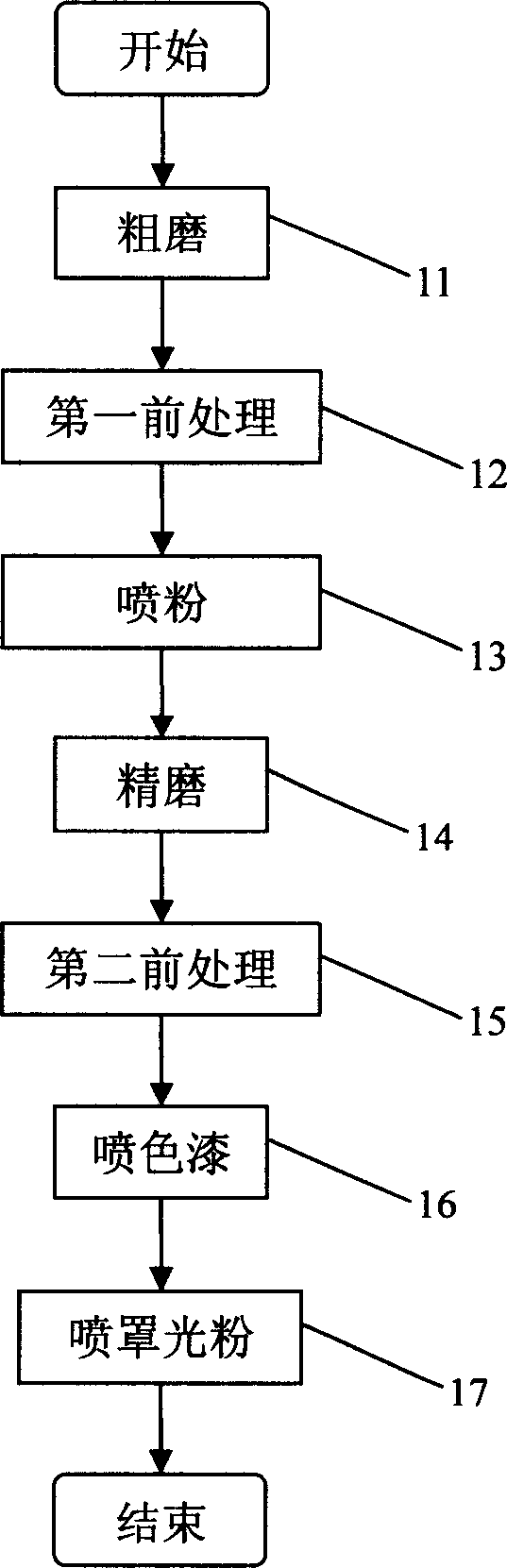

[0026] Such as figure 2 Shown is the flow chart of the coating steps in the electroplating method of the aluminum alloy product of the present invention; coating 1 mainly includes coarse grinding 11, first pretreatment 12, powder spraying 13, fine grinding 14, second pretreatment 15, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com