Suspension type steam generator

A steam generator and suspension technology, which is applied in steam generation, steam generation methods, lighting and heating equipment, etc., can solve the problems of consuming the internal energy of water molecules, consuming a lot of energy, and losing, so as to improve production and life efficiency and save energy. energy, speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

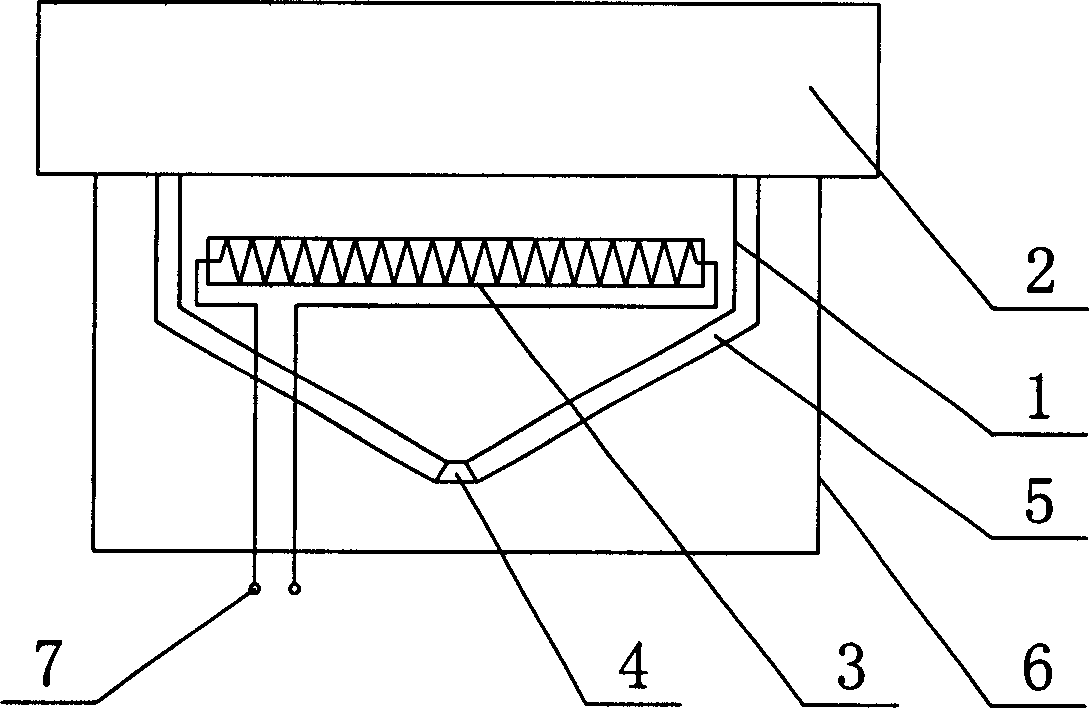

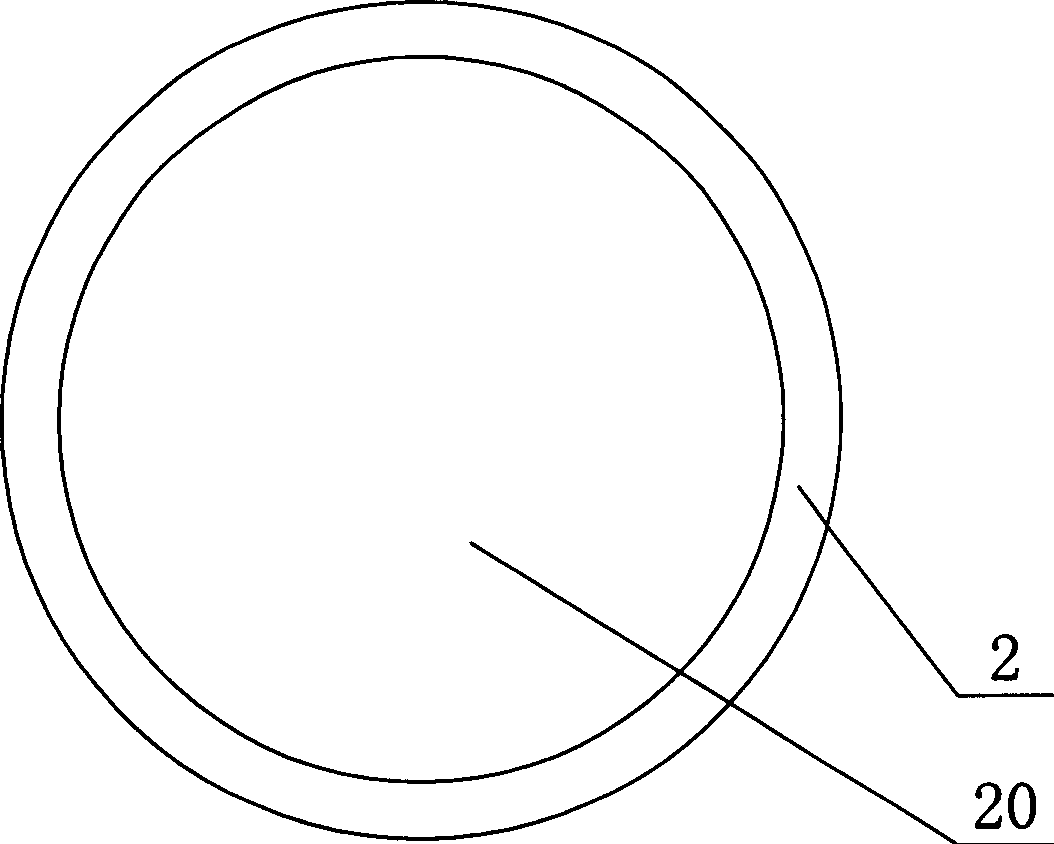

[0024] Such as figure 1 , image 3 , Figure 5 As shown, the present invention includes a container 1, a floating body 2, and an electric heater 3. The top of the container 1 is open, the bottom is provided with a communication port 4, and the wall of the container is provided with an insulating layer 5. The bottom surface of the container 1 is a conical surface. The outside of the container 1 is provided with a protective cover 6 to protect the container 1 from impact, the floating body 2 is fixedly connected to the upper part of the container 1, the floating body 2 is an annular body, and the center of the floating body 2 is set There is a large steam hole 20, the edge is fixedly connected with the container 1, the electric heater 3 is located inside the container 1, the electric heating wire of the electric heater 3 is connected with the power connector 7, and the present invention is put into the water It should be ensured that the electric heater 3 is immersed below the...

Embodiment 2

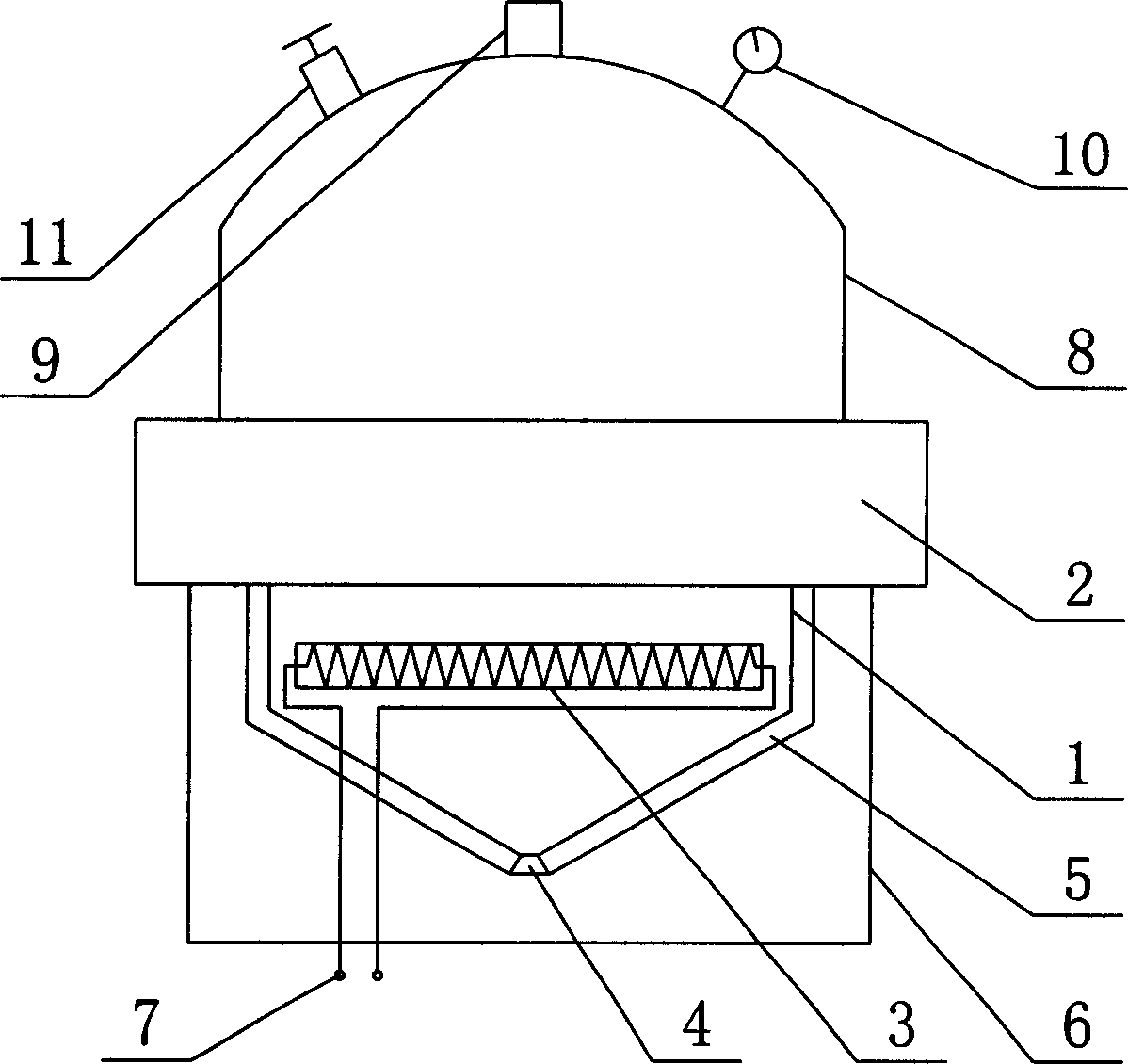

[0027] Such as figure 2 , Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that it also includes a steam collecting hood 8, which is fixedly connected to the upper part of the floating body 2, and the top of the steam collecting hood 8 is provided with a steam Outlet 9, pressure gauge 10, pressure relief valve 11, the steam collecting cover 8 is convenient for steam collection, and the floating body 2 is provided with seven small steam holes 21 evenly spaced. All the other features are the same as in Embodiment 1.

Embodiment 3

[0029] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the container 1 in this embodiment is not provided with a protective cover 6, and the floating body 2 is divided into several independent small pieces that are fixedly connected to the container. 1, all the other features are the same as in Embodiment 1. The present embodiment is characterized in that it is light and handy.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap